Method for treating wastewater of terephthalic acid by using aerating bio filter

An aerated biological filter and terephthalic acid technology, which is applied in the field of environmental engineering, can solve the problems of large pH change range, large water volume fluctuation, and high organic matter concentration, and achieves low engineering investment, low operating costs, and small land occupation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

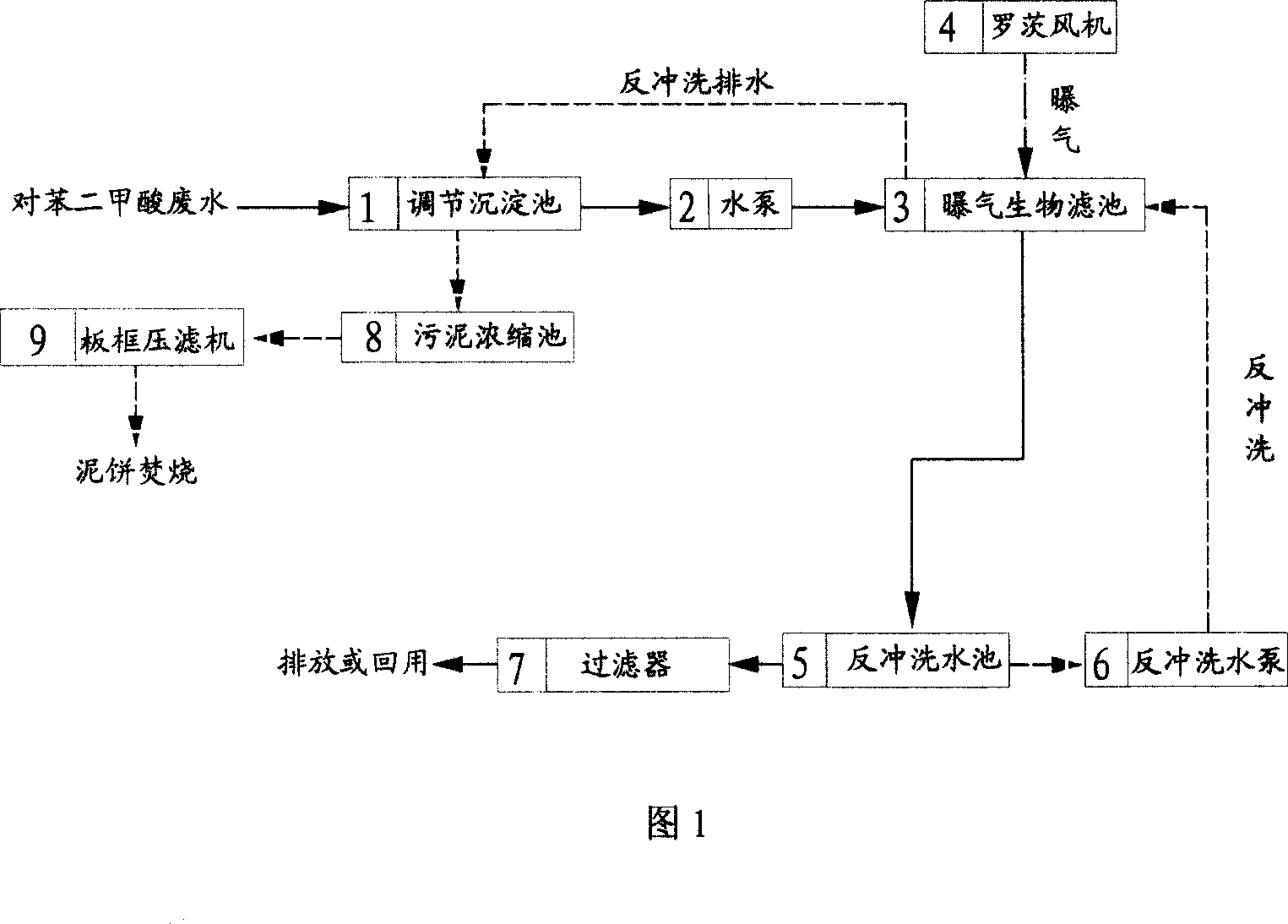

[0024] The biological purification process of terephthalic acid (TA) wastewater of the present invention first adopts the process of secondary filtration after the biological purification of the primary aerated biological filter, and its process flow is shown in Figure 1. The process is as follows: TA wastewater is injected into the bottom of the biological aerated filter 3 by the water pump 2 through the regulated sedimentation tank 1, and enters the filter material layer through the long handle filter head inside the tank, and at the same time, the Roots blower 4 aerates and oxygenates the filter material layer , the effluent enters the filter 7 through the backwash pool 5; the effluent from the filter 7 meets the water quality requirements of general industrial water, and can be directly discharged or reused. The backwashing of biological aerated filter 3 adopts air-water combined backwashing. The method is to use the compressed air provided by Roots blower 4 to backwash for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com