Method for preparing polyurethane, and polyurethane prepared from the method, and usage

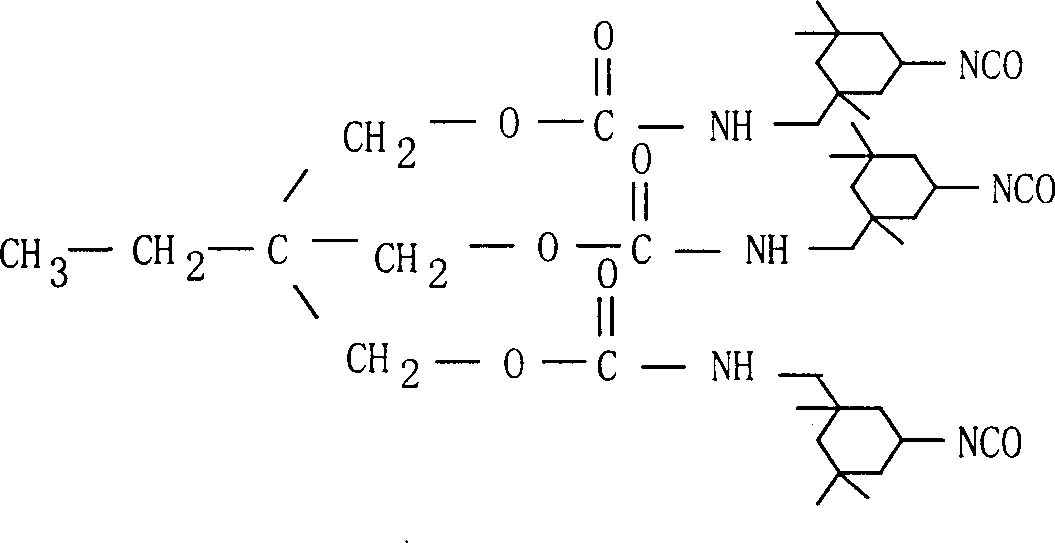

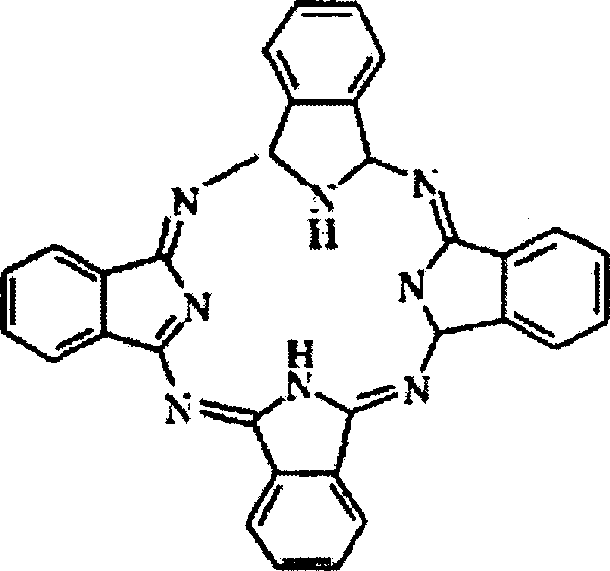

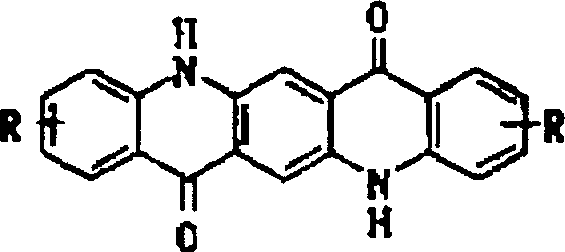

A polyurethane and trimer technology, applied in chemical instruments and methods, transportation and packaging, dissolution and other directions, can solve the problems of insufficient stability of heterocyclic organic pigments and inability to play a stabilizing role, and achieve good adsorption stability and good adsorption. Stable performance and improved tolerance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Table 1

[0039] raw material

Dosage

IPDI homotrimer ①

PEG2000

Polyε-caprolactone monohydric alcohol (M w =1500)

mixed solvent ②

1.0mol

0.3mol

1.0mol

0.25mol

Accounting for 0.05wt% of the total amount of the above 4 raw materials

4000g

[0040] ① IPDI homotrimer was purchased from Degussa Company, trade name T1890;

[0041] ② A mixed solvent of isobutanol and propylene glycol methyl ether acetate with a weight ratio of 1:1.

[0042] The PEG2000 was dehydrated under vacuum at 115°C for 3 hours to obtain dry PEG2000, which was set aside. In the dry four-neck bottle reaction bottle that stirrer, dropping funnel, condenser and thermometer are equipped with, add IPDI homopolymerization trimer, account for the solvent of 70% solvent total amount, catalyzer dibutyl tin dilaurate, pass Under the protection of nitrogen, stir and heat to 75°C; slowly add polyε-ca...

Embodiment 2

[0045] ③A mixed solvent of isobutanol and propylene glycol methyl ether acetate with a weight ratio of 1:1

[0046] The PEG2000 was dehydrated under vacuum at 115°C for 3 hours to obtain dry PEG2000, which was set aside. In the dry four-neck bottle reaction bottle that stirrer, dropping funnel, condenser and thermometer are equipped with, add IPDI homopolymerization trimer, account for the solvent of 70% solvent total amount, catalyzer dibutyl tin dilaurate, pass Under nitrogen protection, stir and heat to 75°C; slowly add polyε-caprolactone monohydric alcohol and a mixed solvent accounting for 10% of the total solvent to the reaction flask, and react at 80°C for 1 hour; then dehydrated PEG2000 and account for the total solvent Mix 15% of the solvent evenly and add it dropwise into the reaction bottle, react at 80°C for 1 hour; slowly raise the temperature to 90°C and keep it warm for 1 hour; finally cool down to 80°C, add the mixture of imidazole and the remaining solv...

Embodiment 3

[0049] ④ A mixed solvent of isobutanol and propylene glycol methyl ether acetate with a weight ratio of 1:1

[0050] The PEG2000 was dehydrated under vacuum at 115°C for 3 hours to obtain dry PEG2000, which was set aside. In the dry four-neck bottle reaction bottle that stirrer, dropping funnel, condenser and thermometer are equipped with, add IPDI homopolymerization trimer, account for the solvent of 70% solvent total amount, catalyzer dibutyl tin dilaurate, pass Under nitrogen protection, stir and heat to 75°C; slowly add polyε-caprolactone monohydric alcohol and a mixed solvent accounting for 10% of the total solvent to the reaction flask, and react at 80°C for 1 hour; then dehydrated PEG2000 and account for the total solvent Mix 15% of the solvent evenly and add it dropwise into the reaction bottle, react at 80°C for 1 hour; slowly raise the temperature to 90°C and keep it warm for 1 hour; finally cool down to 80°C, add the mixture of triazine and the remaining solv...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com