Treatment method and device for sulfur dioxide-containing waste gas

A technology for sulfur dioxide and treatment methods, which is applied in gas treatment, chemical instruments and methods, separation methods, etc., and can solve problems such as inappropriate adsorption materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

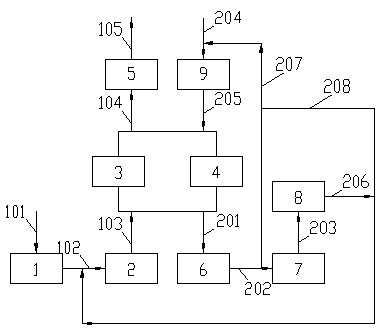

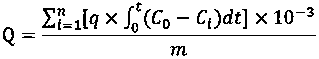

Method used

Image

Examples

Embodiment 1

[0030] Contains SO 2 The gas is catalytic cracking regeneration flue gas, which is pretreated by dust removal, cooling, dehydration and drying before compression, and SO in the exhaust gas after treatment 2 The volume concentration is 0.05~0.2% (about 285~5700mg / m 3 ), O 2 The volume concentration is 3%~5%, and the flue gas treatment capacity is 1000Nm 3 / h.

[0031] Preparation of modified MIL-(Al) metal-organic framework material: Take MIL-100(Al) as the matrix and the specific surface area is 1180m 2 / g, the pore volume is 0.64cm 3 / g, the Al content is 15.2%. In the presence of nitrogen, after carbonization at 800°C for 6 hours, it was immersed and stirred in a 10% hydrochloric acid solution with mass concentration for 12 hours for pickling, filtered and dried at 100°C for 8 hours. Put the above materials in an aqueous solution of ethylenediamine with a volume concentration of 30%, in the presence of nitrogen, modify at 600°C for 1 hour to obtain SO 2 Adsorption material. Aft...

Embodiment 2

[0035] Contains SO 2 The gas is S-zorb adsorbent regeneration flue gas, which is pretreated by dust removal, cooling, dehydration and drying before compression, and SO in the exhaust gas after treatment 2 The volume concentration is 2%~5%, O 2 The volume concentration is less than 0.2%, and the flue gas processing capacity is 500Nm 3 / h.

[0036] Preparation of modified MIL-(Al) metal-organic framework material: Take MIL-100(Al) as the matrix and the specific surface area is 1180m 2 / g, the pore volume is 0.64cm 3 / g, the Al content is 15.2%. In the presence of nitrogen, after carbonization at 800°C for 6 hours, it was immersed and stirred in a 10% hydrochloric acid solution with mass concentration for 12 hours for pickling, filtered and dried at 100°C for 8 hours. Put the above materials in an aqueous solution of ethylenediamine with a volume concentration of 30%, in the presence of nitrogen, modify at 600°C for 1 hour to obtain SO 2 Adsorption material. After testing, the speci...

Embodiment 3

[0040] Contains SO 2 The gas is catalytic cracking regeneration flue gas, which is pretreated by dust removal, cooling, dehydration and drying before compression, and SO in the exhaust gas after treatment 2 The volume concentration is 0.05%~0.2%, O 2 The volume concentration is 3%~5%, and the flue gas treatment capacity is 1000Nm 3 / h.

[0041] Preparation of modified MIL-(Al) metal-organic framework material: Take MIL-100(Al) as the matrix and the specific surface area is 1180m 2 / g, the pore volume is 0.64cm 3 / g, the Al content is 15.2%. In the presence of nitrogen, after carbonization at 800°C for 6 hours, it was immersed and stirred in a 10% hydrochloric acid solution with mass concentration for 12 hours for pickling, filtered and dried at 100°C for 8 hours. Put the above materials in an aqueous solution of ethylenediamine with a volume concentration of 30%, in the presence of nitrogen, modify at 600°C for 1 hour to obtain SO 2 Adsorption material. After testing, the specifi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com