Method for preparing anthoid crystalline magnesium hydroxide film in microcosmic appearance

A magnesium hydroxide, micro-morphology technology, applied in the electrolysis process, electrolysis components and other directions, to achieve the effect of short time, low temperature and energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

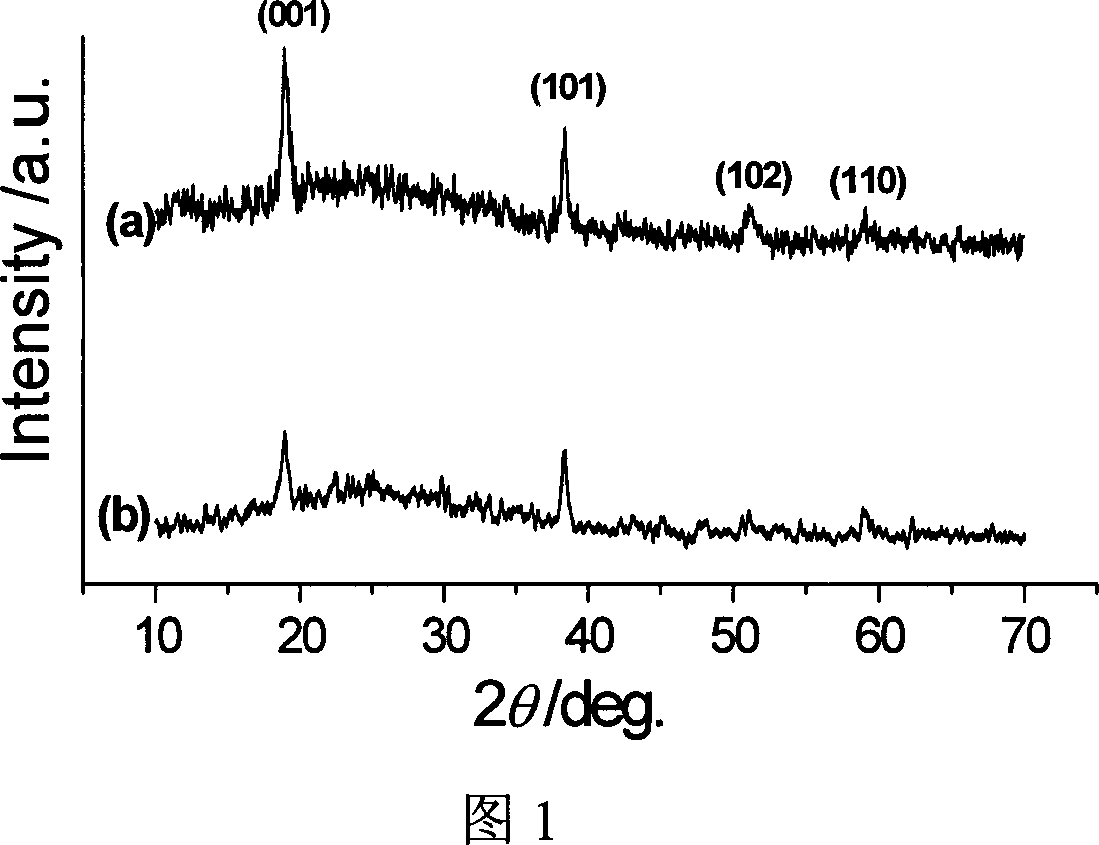

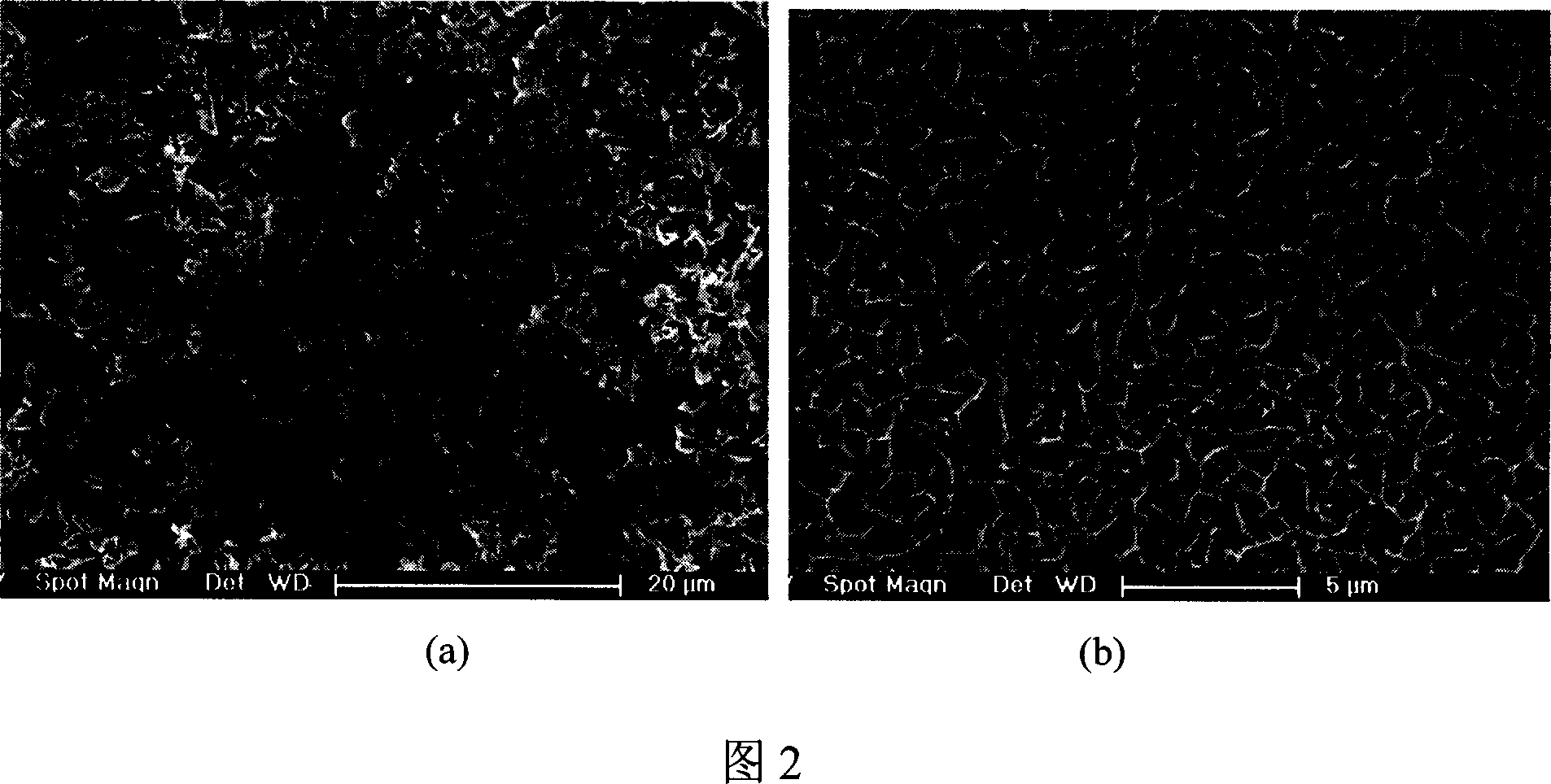

[0036] A traditional glass electrolytic cell was used, with ITO as the cathode, a platinum electrode as the counter electrode, and a saturated calomel electrode (SCE) as the reference electrode. The electrolyte solution is an aqueous solution of 0.1mol / L magnesium nitrate and 0.2 sodium acetate, the cathode potential is at -1.5V (relative to SCE), the time is 2 hours, room temperature. As a comparison, a magnesium nitrate solution without sodium acetate was used as the electrolyte, that is, a 0.1mol / L magnesium nitrate aqueous solution, and other conditions were the same. The prepared magnesium hydroxide thin film was characterized by XRD and SEM.

[0037] The characterization results show that the XRD diffraction peaks of the prepared film (see Figure 1) are consistent with the standard magnesium hydroxide diffraction card, indicating that both are films of magnesium hydroxide. But the SEM result (see Fig. 2) shows that the film prepared from the cathode electrodeposition of...

Embodiment 2

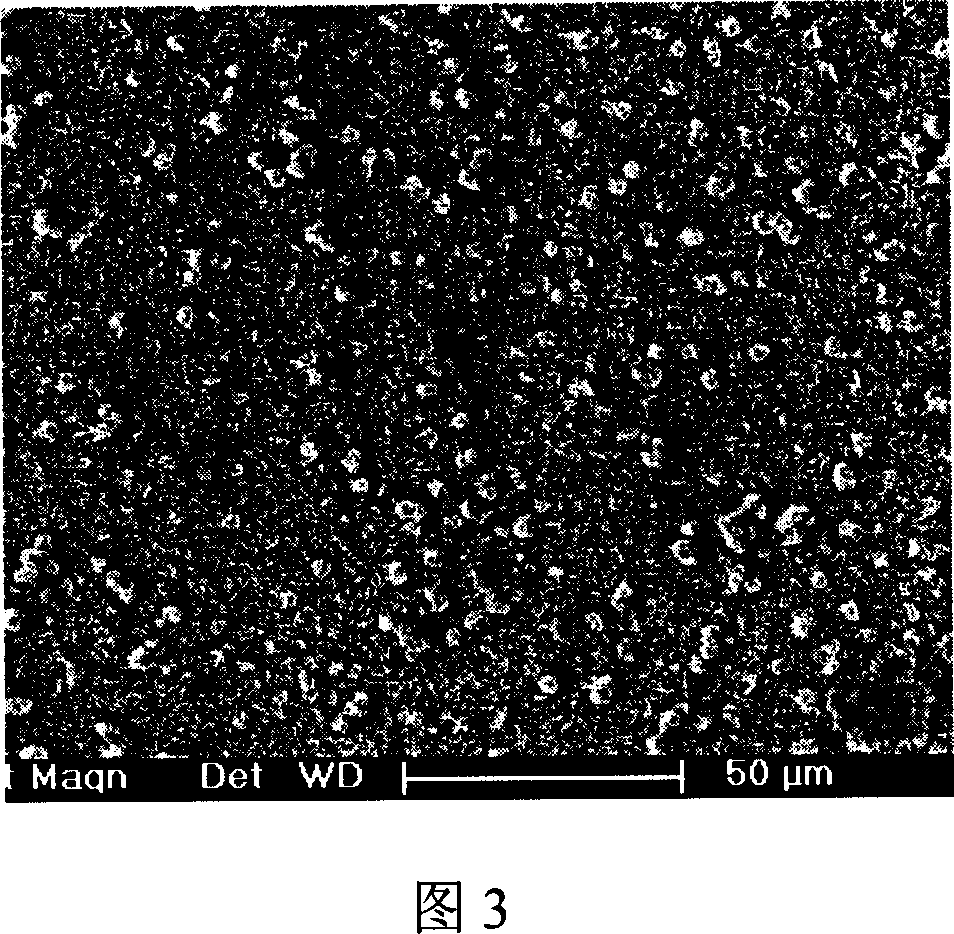

[0039] A traditional glass electrolytic cell was used, with ITO as the cathode, a platinum electrode as the counter electrode, and a saturated calomel electrode (SCE) as the reference electrode. The electrolyte solution is an aqueous solution of 0.1mol / L magnesium nitrate and 0.025 sodium acetate, the cathode potential is at -1.5V (relative to SCE), the time is 2 hours, room temperature.

[0040] XRD characterization results show that the prepared film is magnesium hydroxide film. The SEM results (see Figure 3) show that the magnesium hydroxide film is composed of magnesium hydroxide with flower-like crystal morphology and porous network magnesium hydroxide, wherein the ratio of magnesium hydroxide with flower-like crystal morphology in the film is about 5-5. 7%.

Embodiment 3

[0042] A traditional glass electrolytic cell was used, with ITO as the cathode, a platinum electrode as the counter electrode, and a saturated calomel electrode (SCE) as the reference electrode. The electrolyte solution is an aqueous solution of 0.1mol / L magnesium nitrate and 0.1 sodium acetate, the cathode potential is -1.5V (relative to SCE), the time is 2 hours, room temperature.

[0043] XRD characterization results showed that the films prepared by cathodic electrodeposition were all magnesium hydroxide films. SEM results (see Figure 4) show that the magnesium hydroxide film is composed of magnesium hydroxide with flower-shaped crystal morphology and porous network magnesium hydroxide, wherein the ratio of magnesium hydroxide with flower-shaped crystals in the film is about 40~ 60%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com