N, N'- dicyclohexyl thiourea microwave synthesis method

A technology of dicyclohexylthiourea and microwave synthesis, applied in the N field, can solve the problems of expensive reagents, hidden dangers, long reaction time, etc., and achieve the effects of simple feeding and post-processing, mild reaction conditions, and short reaction time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

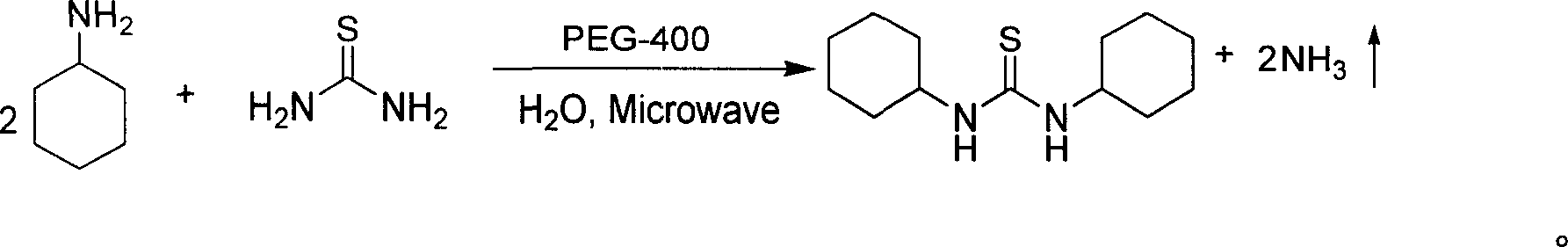

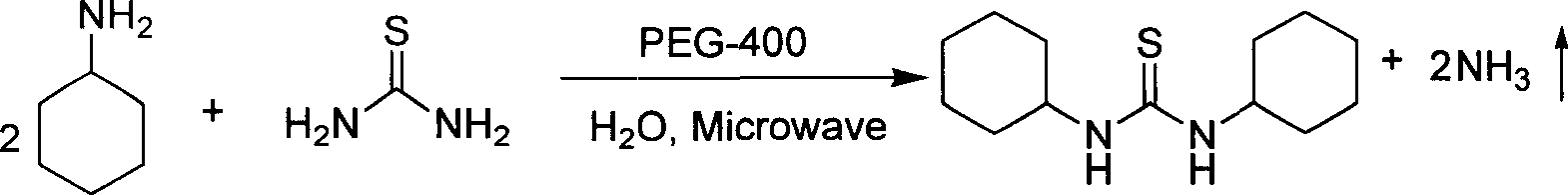

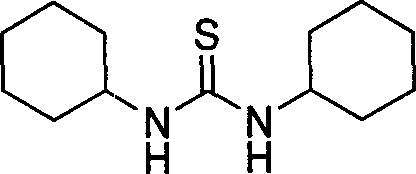

[0014] The specific reaction steps of the microwave synthesis method of N, N '-dicyclohexylthiourea are as follows:

[0015] With water as the reaction solvent and PEG-400 as the catalyst, thiourea and cyclohexylamine are heated and reacted in microwave for 0.5 to 2 minutes. After filtration and washing, high yield and high purity N,N'-dicyclohexylsulfide can be obtained by separation. Urea; reaction solvent and catalyst can be recycled. The molar equivalent ratio of thiourea and cyclohexylamine is 0.4-0.6:1; the dosage of catalyst PEG-400 is 1-5% molar equivalent of thiourea; the microwave frequency is 2450MHz; the microwave power is 400-800W. It is recommended that the molar equivalent ratio of thiourea and cyclohexylamine be 0.45-0.55:1, and the most preferred ratio is 0.5:1; the recommended dosage of catalyst PEG-400 is 1-4% molar equivalent of thiourea, and the most preferred is 3% molar equivalent. The recommended microwave power is 500-700W, with 600W being the most p...

Embodiment 1

[0018] Mix 10 mmoles of thiourea, 20 mmoles of cyclohexylamine and 0.3 mmoles of PEG-400 in 15 milliliters of water, set the microwave power to 600W, heat the reaction for 1 minute, end the reaction, cool down, precipitate the product, filter (the filtrate is recovered ), washed with water, and dried to obtain 2.2 grams of N, N'-dicyclohexylthiourea, with a yield of 92% and a melting point of 180-182°C.

Embodiment 2

[0020] Mix 8 millimoles of thiourea and 20 millimoles of cyclohexylamine in the filtrate recovered in Example 1, set the microwave power to 650W, heat the reaction for 1 minute, end the reaction, cool, separate out the product, filter (recover the filtrate) , washed with water, and dried to obtain N,N'-dicyclohexylthiourea with a yield of 76% and a melting point of 179-182°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com