Method for preparing uridine diphosphate

A technology of uridine diphosphate and uridine triphosphate, applied in microorganism-based methods, biochemical equipment and methods, microorganisms, etc., can solve problems such as increased cost, low recovery rate, increased production cost, etc., and achieve shortened time. , The effect of improving product recovery rate and reducing burden

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

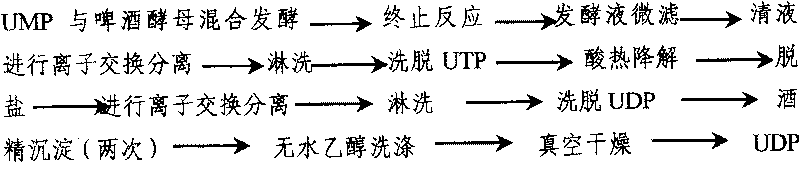

[0060] figure 1 It is the production process flow of uridine diphosphate of the present invention; this embodiment adopts the method of primary fermentation and degradation to produce uridine diphosphate.

[0061] 1. Fermentation

[0062] First, adopt one-step method to ferment uridine monophosphate (6-liter scale), fermentation conditions: UMP318.7g (feeding according to electrophoretic purity 75.3%); Saccharomyces cerevisiae 3kg; Glu 432g; NaH 2 PO 4 280.8g; MgCl 2 24.4g; pH 6.7; H 2 Add O to 6 liters; keep warm at 37°C, and ferment statically for 6 hours.

[0063] Brewer's yeast is eliminated yeast in beer production, and the survival rate of yeast cells is more than 98%, and the content (percentage by weight) of yeast in the dried yeast after pressing is 25%.

[0064] Then use fast paper electrophoresis to track and detect the fermentation products.

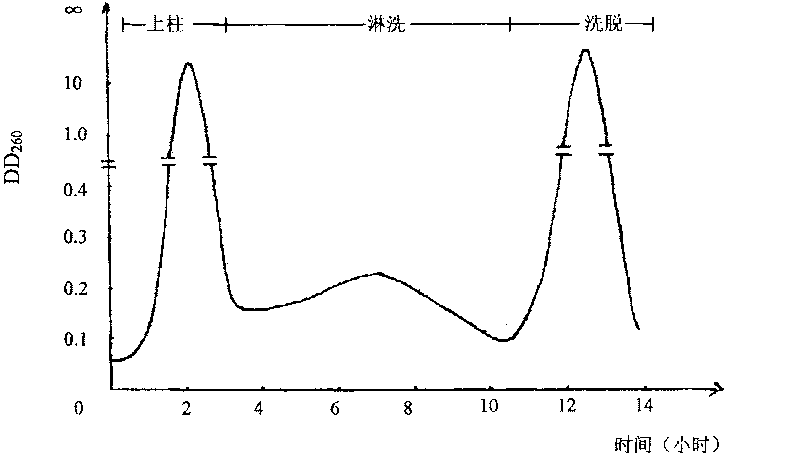

[0065] The pH value was adjusted to 2.0 with trichloroacetic acid, the fermentation was terminated, and the ferment...

Embodiment 2

[0105] 1. Fermentation

[0106] First, adopt one-step method to ferment uridine monophosphate (5 liter scale), fermentation conditions: UMP 240g (feeding according to electrophoretic purity 75.3%); Saccharomyces cerevisiae 2.4kg; Glu 312g; NaH 2 PO 4 216g; MgCl 2 57.1g; pH 6.2; H 2 Add O to 5 liters; keep warm at 32°C and ferment statically for 8 hours.

[0107] Brewer's yeast is eliminated yeast in beer production, and the survival rate of yeast cells is more than 90%, and the yeast content (percentage by weight) in the dried yeast after pressing is 20%.

[0108] Then use fast paper electrophoresis to track and detect the fermentation products.

[0109] The pH value was adjusted to 3.0 with trichloroacetic acid to terminate the reaction, and the fermentation conversion rate was 78.9%.

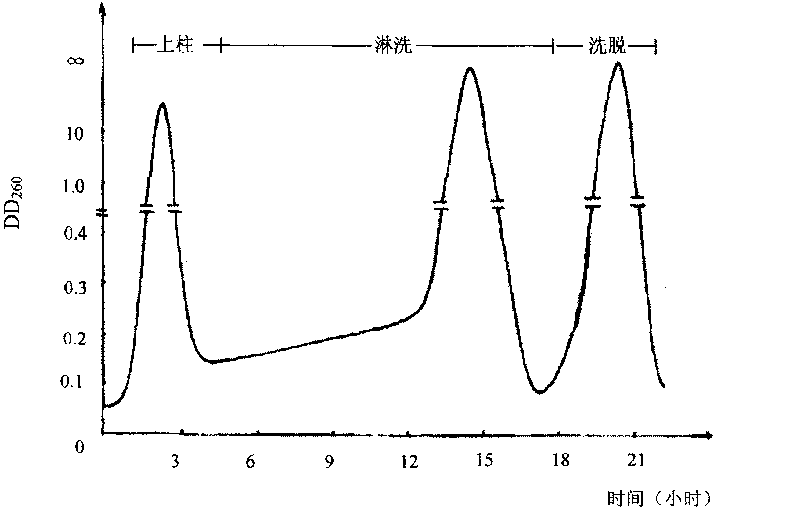

[0110] 2. Microfiltration to remove protein:

[0111] Use an inorganic ceramic membrane with a pore size of 0.1 μm to treat the fermentation broth. Before microfiltration, pass through ...

Embodiment 3

[0148] The basic steps are the same as in Example 1, except that during one-step fermentation, fermentation conditions: UMP 500g (feeding according to electrophoretic purity 75.3%); brewer's yeast (fresh) 3.5kg; Glu 493.8g; NaH 2 PO 4 360g; MgCl 2 5.71g; pH7.0; H 2 Add O to 8 liters; keep warm at 39°C, and ferment statically for 7 hours. The fermentation conversion rate was 77.5%.

[0149] When using 717 chlorine type strong base anion exchange resin for UTP separation and purification, the upper column: pH 2.5, upper column flow rate 26L / hr; low salt elution: 0.02N, pH 2.0NaCl solution; elution flow rate 26L / hr; Salt elution: 0.5N NaCl, pH 2.0 solution; elution flow rate 2.8L / hr.

[0150] Loading volume: 2.36% of the total exchange volume of 717 resin, that is, 40mg UTP / ml resin,

[0151] For acid-thermal degradation, the pH value was first adjusted to 1.2 with 6N hydrochloric acid, heated and boiled for 30 minutes, and detected by high performance liquid phase and pap...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com