Double-purpose oxygen pole used for integral reproducible fuel battery and its manufacturing method

A double-effect oxygen electrode and fuel cell technology, which is applied to fuel cell components, fuel cells, battery electrodes, etc., to achieve the effects of easy pore structure and pore distribution, improved cycle life, and high battery performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

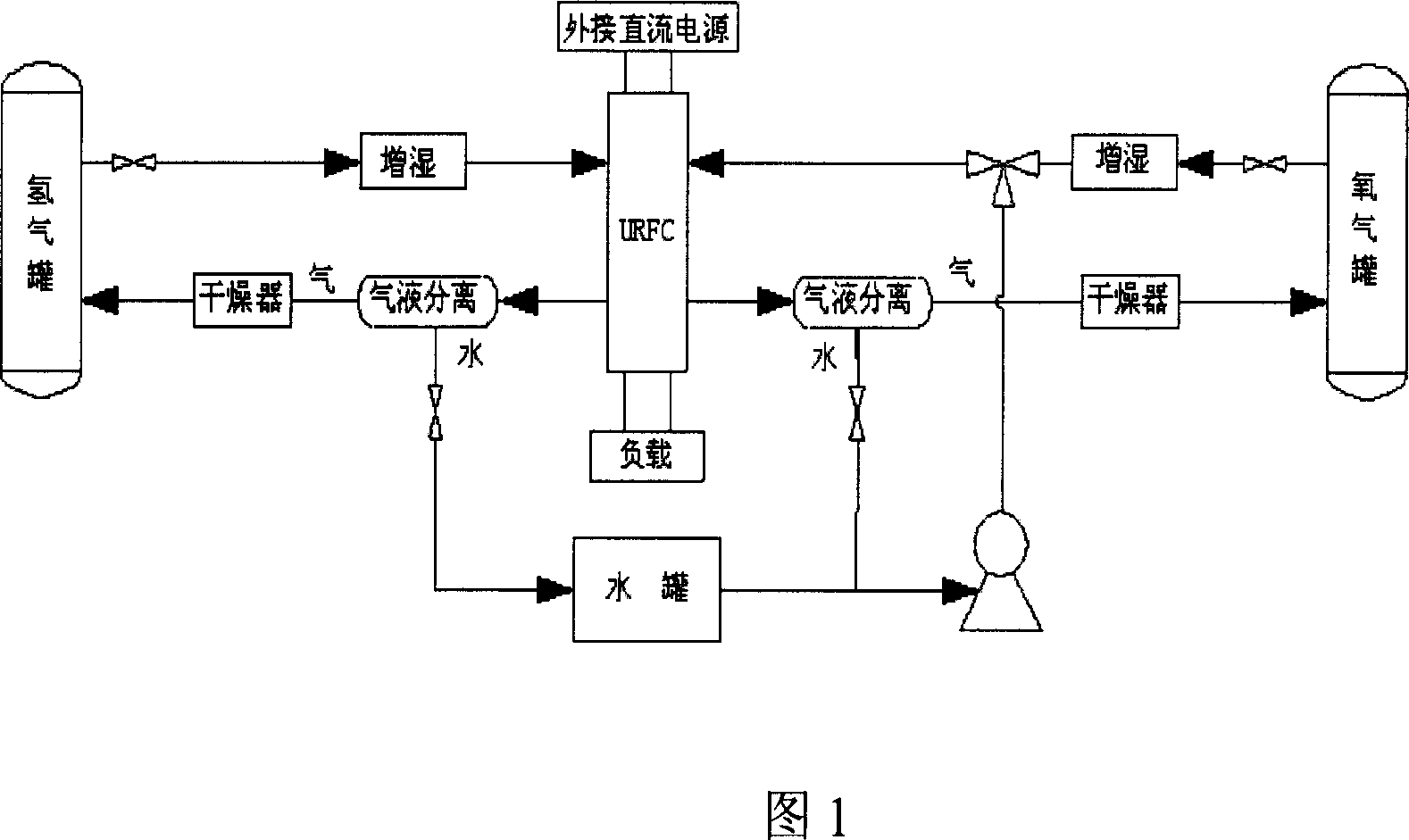

Method used

Image

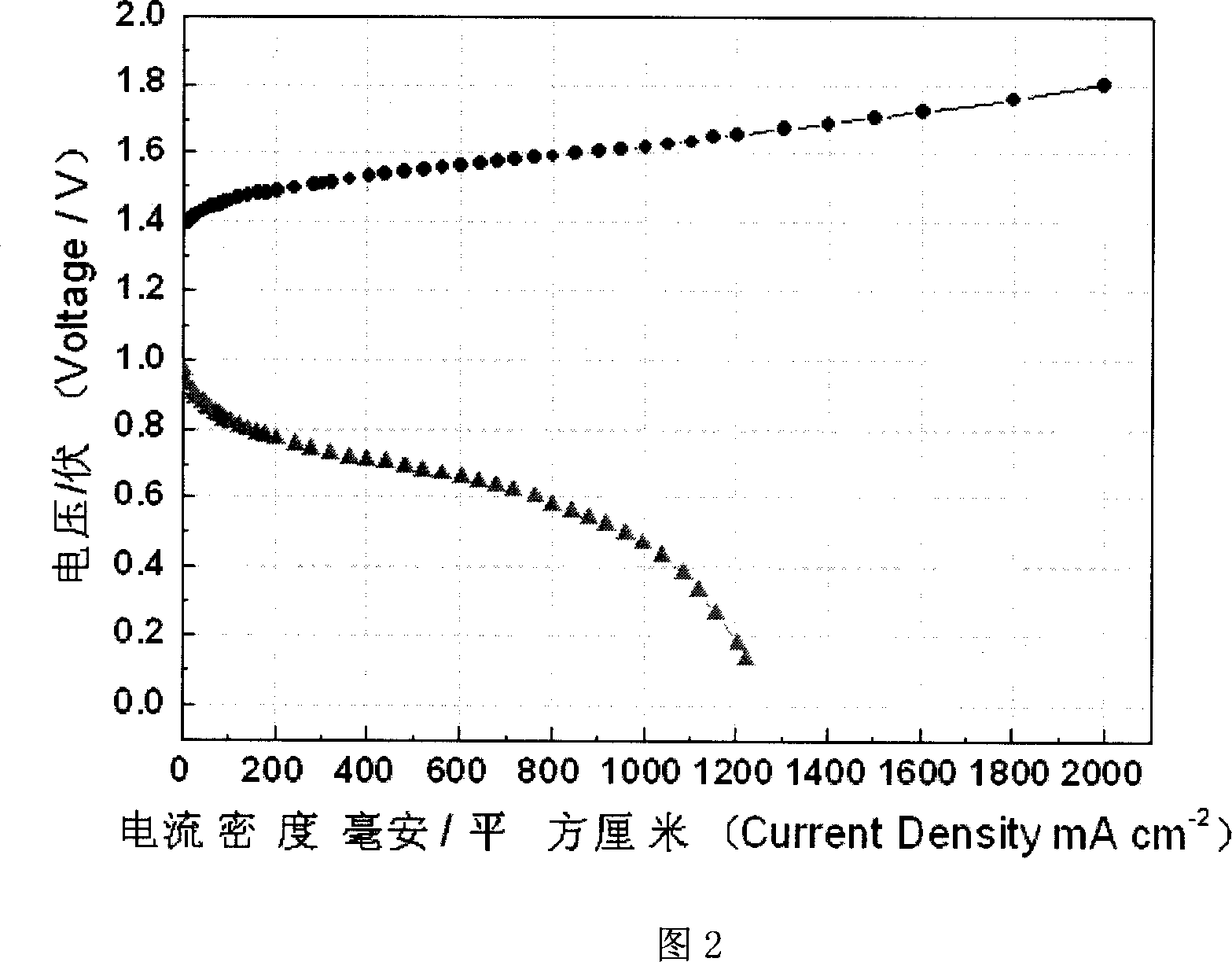

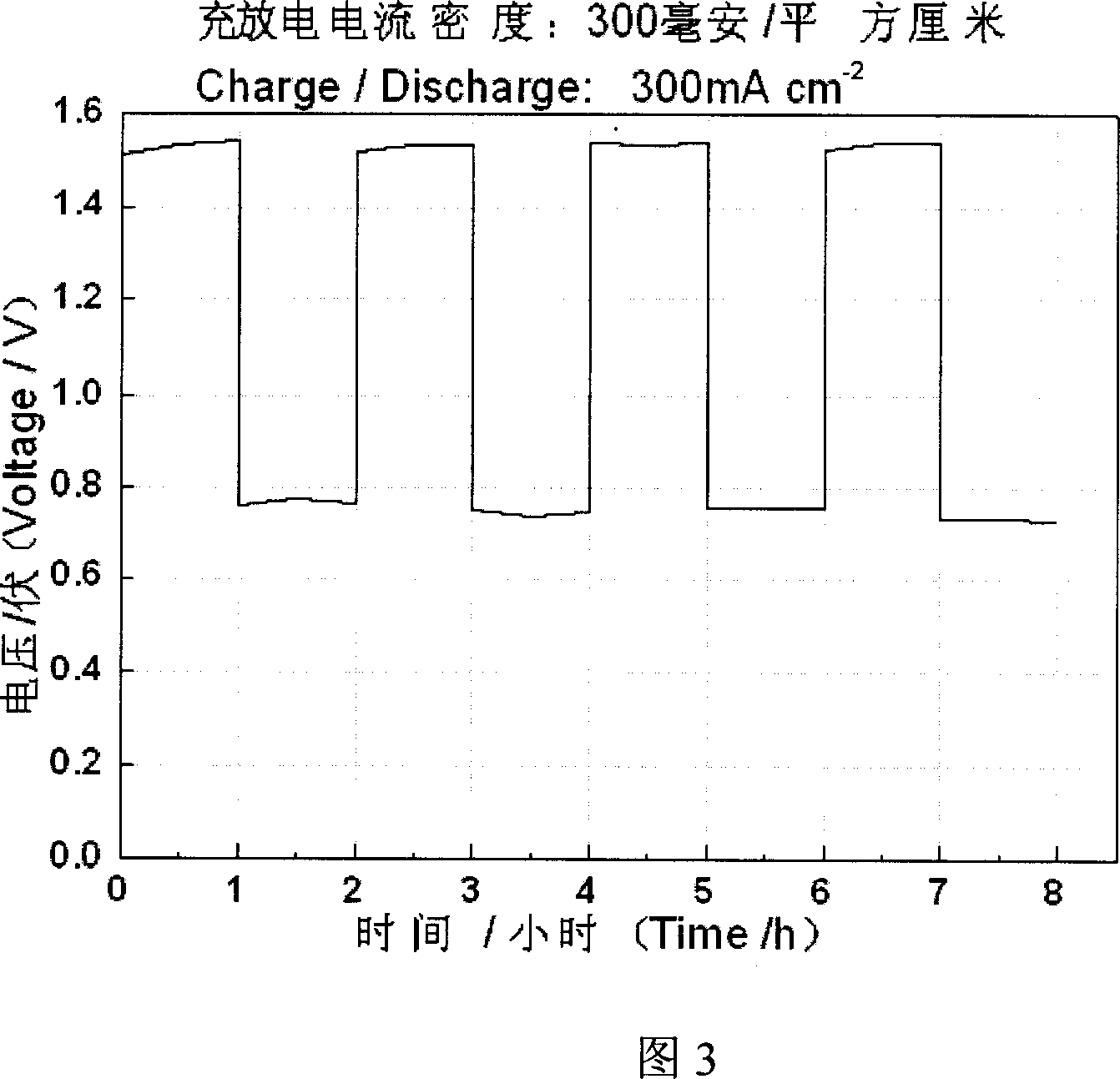

Examples

Embodiment 1

[0044] Weigh out 1.1485 g H 2 IrCl 6 ·XH 2 O dissolved in 530ml 0.038mol L -1 In the NaOH solution, at 40°C, N 2 Stir continuously for 4 h under the same conditions, cool to 5°C, add 0.5 g of Pt black, and add 0.1 mol L -1 HClO 4 Adjust the pH value to 8 to obtain a black-yellow precipitate, filter it with suction, wash it, dry it in vacuum, and sinter it at 500°C for 1 hour to obtain 1 g of IrO loaded on Pt. 2 Catalyst (mass ratio 1:1).

[0045] Cut 2×2.5cm 2 The carbon paper was dipped in 60% PTFE emulsion (polytetrafluoroethylene) for hydrophobic treatment, and then fired at 360° C. for 1 hour to obtain the hydrophobic carbon paper. IrO on 10 mg Pt 2 Add ethanol to the catalyst (mass ratio 1: 1), add 11.1 mg of 60% PTFE emulsion after mixing evenly, obtain a catalytic leveling layer slurry after ultrasonic mixing, apply the slurry evenly on carbon paper, and then heat it at 360°C The multifunctional diffusion layer was obtained by lower firing for 1 hour.

[0046]...

Embodiment 2

[0048] Weigh out 1.1485 g H 2 IrCl 6 ·XH 2 O dissolved in 530ml 0.038mol L -1 In the NaOH solution, at 40°C, N 2 Stir continuously for 4 h under the same conditions, cool to 5°C, add 0.5 g of Pt black, and add 0.1 mol L -1 HClO 4 Adjust the pH value to 8 to obtain a black-yellow precipitate, filter it with suction, wash it, dry it in vacuum, and sinter it at 500°C for 1 hour to obtain 1 g of IrO loaded on Pt. 2 Catalyst (mass ratio 1:1).

[0049] Cut 2×2.5cm 2 The titanium foam is dipped in 60% PTFE emulsion (polytetrafluoroethylene) for hydrophobic treatment, and then baked at 360°C for 1 hour to make it hydrophobic. IrO on 10 mg Pt 2 Add ethanol in the catalyzer (mass ratio 1: 1), add the PTFE emulsion of 11.1 milligrams of 60% after mixing uniformly, obtain catalytic leveling layer slurry after mixing uniformly, slurry is evenly coated on the foamed titanium of hydrophobization, then Calcined at 360° C. for 1 hour to obtain a multifunctional diffusion layer.

[00...

Embodiment 3

[0052] Weigh out 1.1485 g H 2 IrCl 6 ·XH 2 O dissolved in 530ml 0.038mol L -1 In the NaOH solution, at 40°C, N 2 Stir continuously for 4 h under the same conditions, cool to 5°C, add 0.5 g of Pt black, and add 0.1 mol L -1 HClO 4 Adjust the pH value to 8 to obtain a black-yellow precipitate, filter it with suction, wash it, dry it in vacuum, and sinter it at 500°C for 1 hour to obtain 1 g of IrO loaded on Pt. 2 Catalyst (mass ratio 1:1). .

[0053] Cut 2×2.5cm 2 The porous titanium plate was dipped in 60% PTFE emulsion (polytetrafluoroethylene) for hydrophobic treatment, and then baked at 360° C. for 1 hour to make it hydrophobic. IrO on 10 mg Pt 2 Add ethanol in the catalyst (mass ratio 1: 1), add 11.1 mg of 60% PTFE emulsion after mixing uniformly, obtain catalytic leveling layer slurry after mixing uniformly, and evenly coat the slurry on a hydrophobic porous titanium plate , and then fired at 360°C for 1 hour to obtain a multifunctional diffusion layer.

[0054]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com