Process for preparing micro Azithromycin powder

A technology of azithromycin and micronization is applied in the field of preparation of azithromycin ultrafine powder, which can solve the problems of dust pollution, static electricity, wide particle size distribution, particle agglomeration, etc., and achieves the effects of safe operation, controllable particle size and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

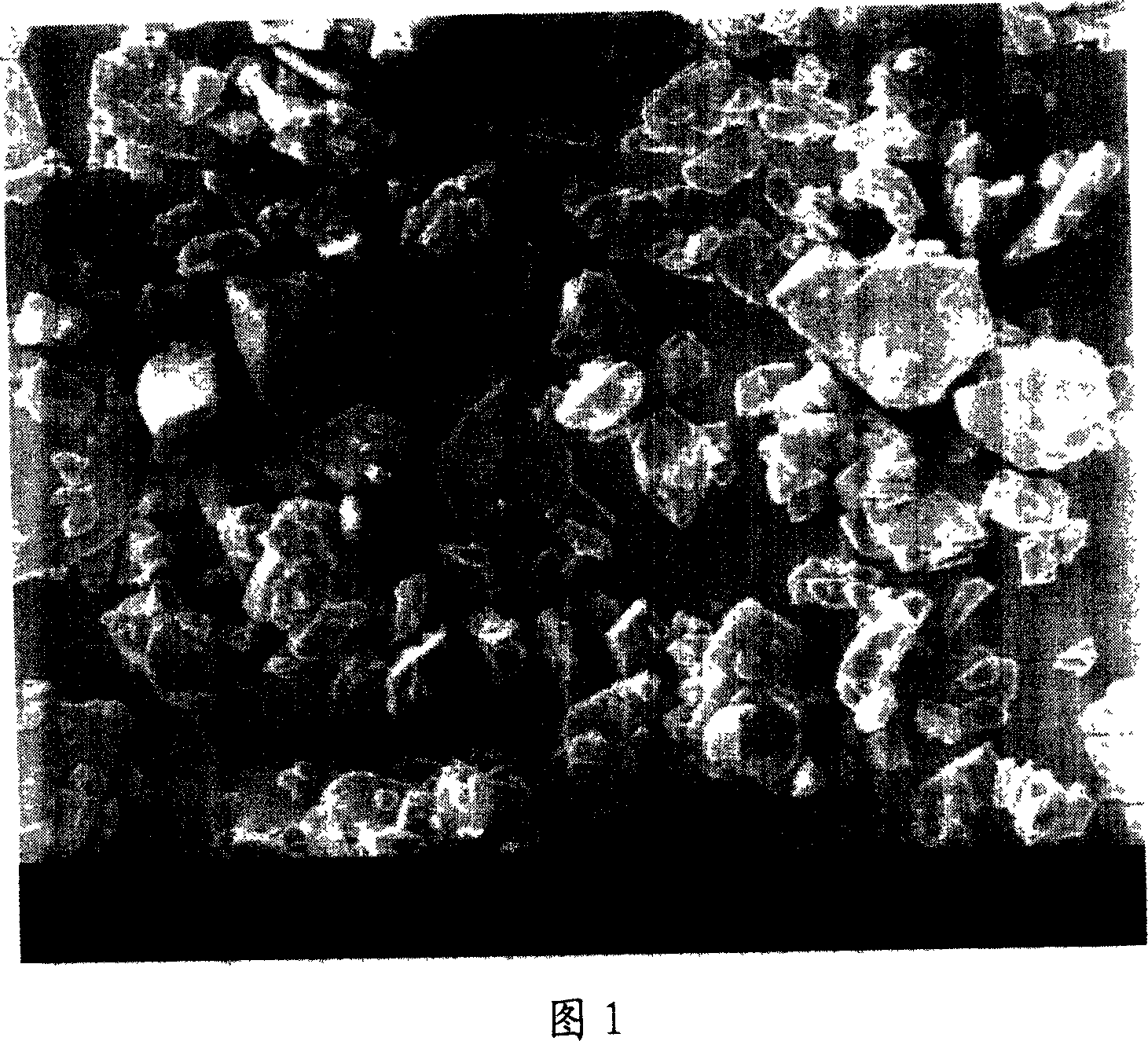

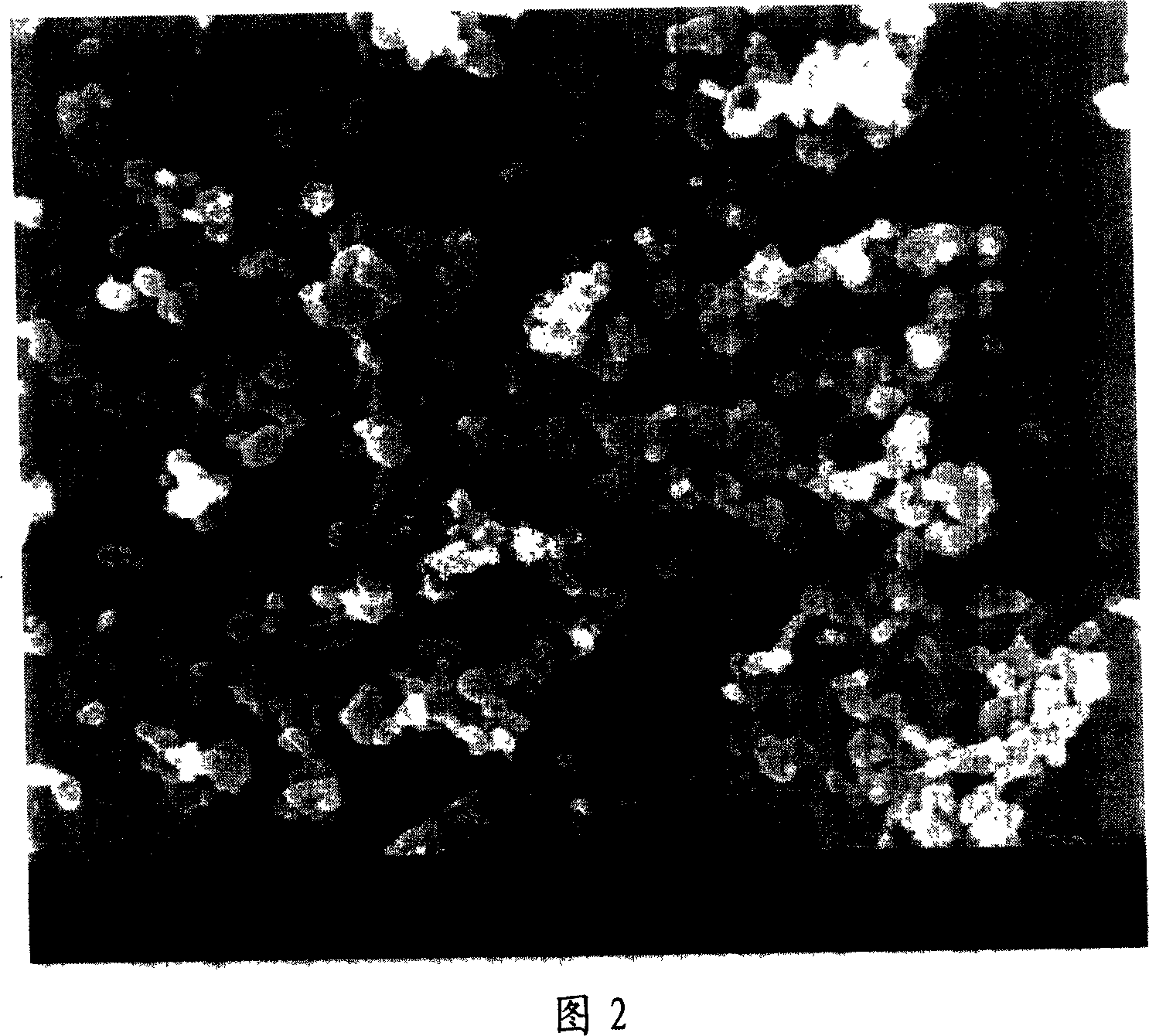

[0033] Adopt the commercially available azithromycin raw material drug that meets the requirements of the Pharmacopoeia, as shown in the scanning electron microscope (SEM) photo in Figure 1, the particle size is between 20-100 μm, and it is a particle with uneven particle size and irregular shape. Azithromycin crude drug is dissolved in dehydrated alcohol, is mixed with the azithromycin raw material solution (in this embodiment is the ethanol of azithromycin raw material) that concentration is 0.2g / ml (being 20 ℃ when azithromycin is in the about 50% of saturated concentration of azithromycin in ethanol). solution). The recrystallization temperature was controlled at 18°C by a constant temperature water bath. Get the ethanol solution 10ml of above-mentioned azithromycin, add rapidly in the reactor that 200ml anti-solvent (water in this embodiment) is housed, that is, the volume ratio of azithromycin raw material solution and anti-solvent is 1: 20, under control stirring spee...

Embodiment 2

[0035] The operating parameters are the same as in Example 1, except that the recrystallization temperature is changed to 30°C. Observed by SEM, the particle morphology of the obtained azithromycin micronized product is similar to that of Example 1, but the average particle size of the particles is about 1 μm, and at least 80% of the particles have a particle size between 0.5-3 μm.

Embodiment 3

[0037]The operating parameters are the same as in Example 1, except that the volume ratio of the azithromycin raw material solution to the anti-solvent (water in this example) is changed to 1:10. Observation of the obtained product by SEM shows that the particle size of the product is basically between 0.5-1 μm, but the agglomeration is serious.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com