Prepn and use of potassium fluorocarbonate

A technology of potassium carbonate and carbonate, applied in the direction of carbonate preparations, etc., can solve the problems of unfavorable environmental protection, waste of carbon dioxide, incomplete reaction of bottom raw materials, etc., and achieve the effect of low cost, complete reaction of raw materials, and easy promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

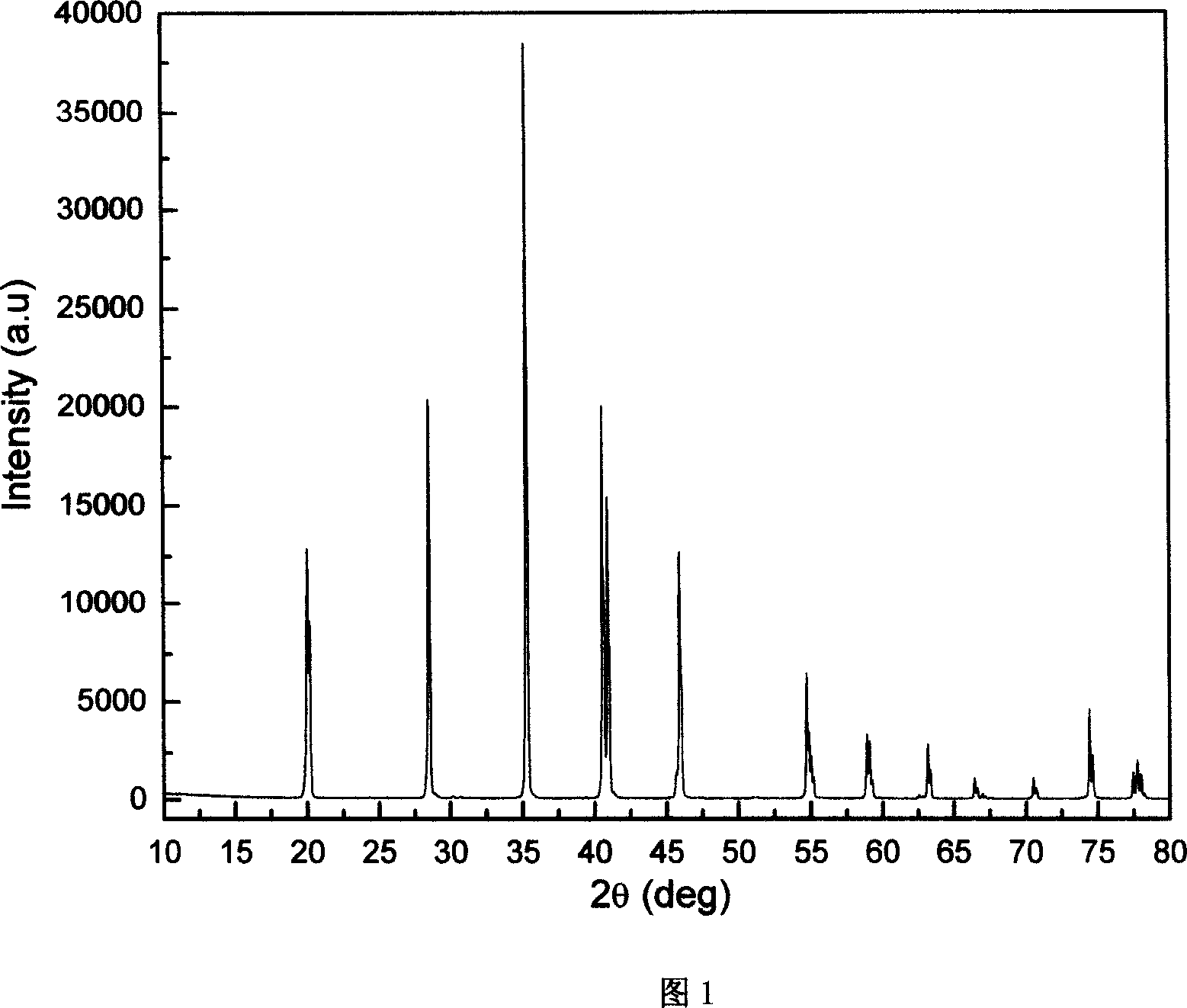

[0019] Take by weighing 0.15 mol of potassium fluoride with a purity of 99.9% and 0.1 mol of calcium carbonate with a purity of 99.9% and grind them in an agate mortar and mix them evenly; put the powder into an iron crucible with a diameter of 90 mm, a height of 180 mm, and a thickness of 10 mm. Put the crucible into the vacuum electromagnetic induction furnace and connect the vacuum system to evacuate to 10 -4 Pa, and then filled with carbon dioxide atmosphere. Under the condition that the pressure of carbon dioxide is 1.2 atmospheres, the rate of 8°C / min is raised from room temperature to 500°C, kept for 10 hours, the power is turned off, and the white target product KCaCO is synthesized. 3 F powder.

Embodiment 2

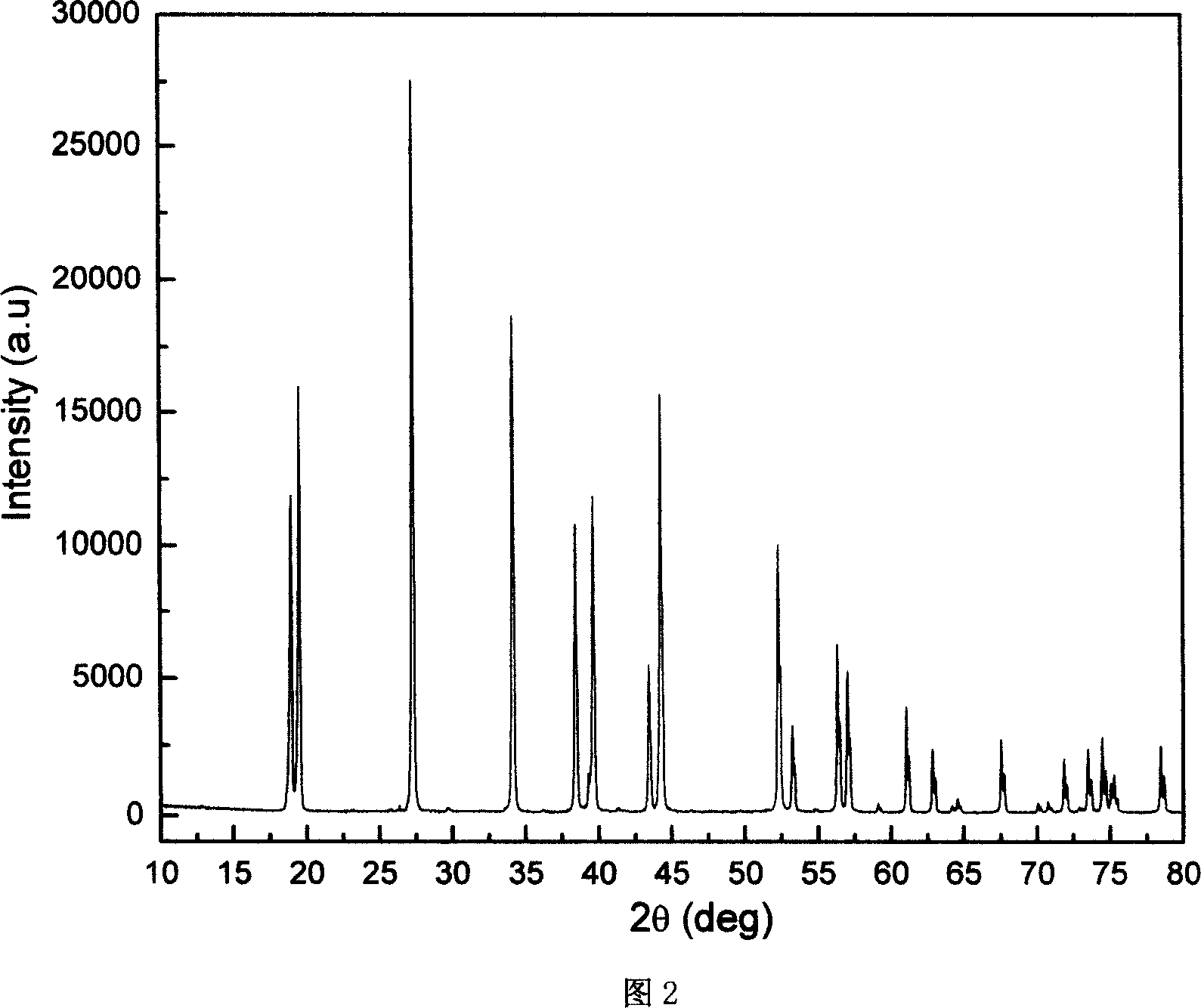

[0021] Take by weighing 0.15 mol of potassium fluoride with a purity of 99.9% and 0.1 mol of strontium carbonate with a purity of 99.9%, grind and mix them uniformly in an agate mortar, put the powder into a platinum crucible with a diameter of 90 mm, a height of 180 mm, and a thickness of 10 mm. Put it into a vacuum electromagnetic induction furnace and connect it to a vacuum system to evacuate to 10 -4 Pa, and then filled with carbon dioxide atmosphere. Under the condition of carbon dioxide pressure of 1.4 atmospheres, the rate of 8°C / min was raised from room temperature to 500°C, kept for 20 hours, turned off the power, cooled with the furnace, and synthesized to obtain the white target product KSrCO 3 Powder of F.

Embodiment 3

[0023] Take by weighing 0.12mol of potassium fluoride with a purity of 99.9% and 0.1mol of calcium carbonate with a purity of 99.9% and grind and mix them uniformly in an agate mortar, put the powder into a tungsten crucible with a diameter of 90mm, a height of 180mm, and a thickness of 10mm. The crucible is loaded into a vacuum electromagnetic induction furnace and connected to a vacuum system to evacuate to 10 -4 Pa, and then filled with carbon dioxide atmosphere. Under the condition of carbon dioxide pressure of 1.3 atmospheres, the rate of 8°C / min was raised from room temperature to 800°C, kept for 20 hours, turned off the power, cooled with the furnace, and synthesized to obtain the white target product KCaCO 3 Powder of F.

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com