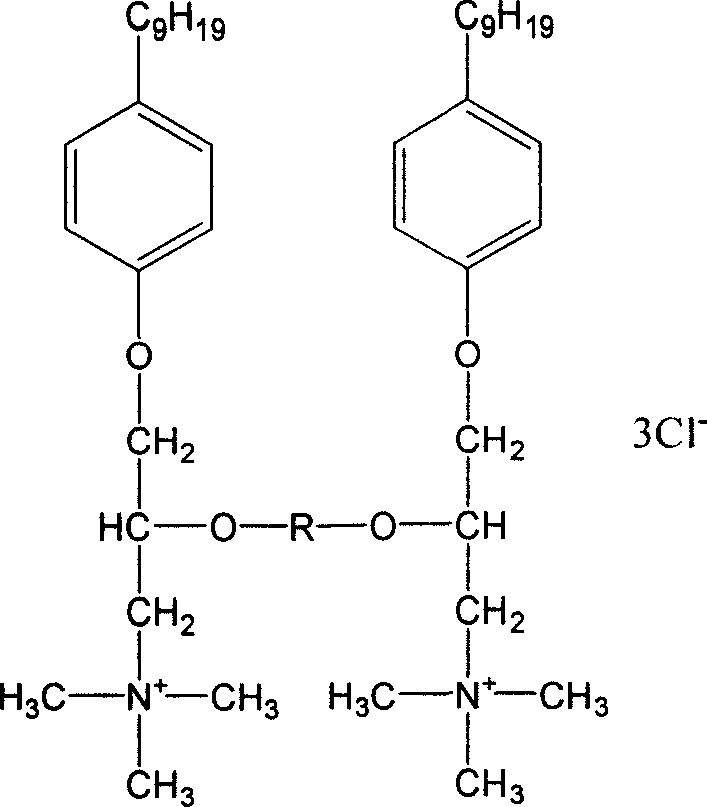

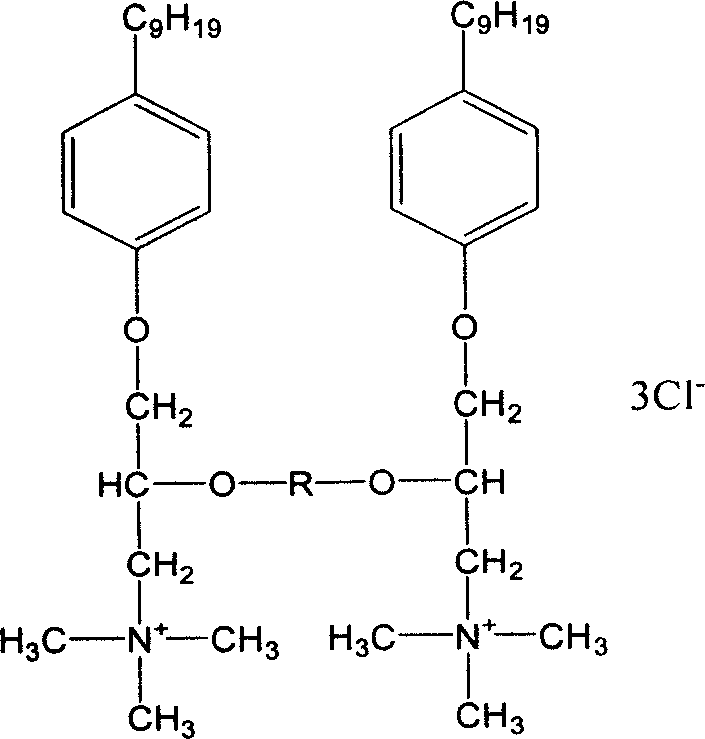

Gemini surfactant and preparing method thereof

A technology of surfactants and gemini surfaces, applied in chemical instruments and methods, dissolution, chemical/physical processes, etc., can solve problems such as reducing the surface activity of surfactants, loose arrangement, and limiting the scope of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

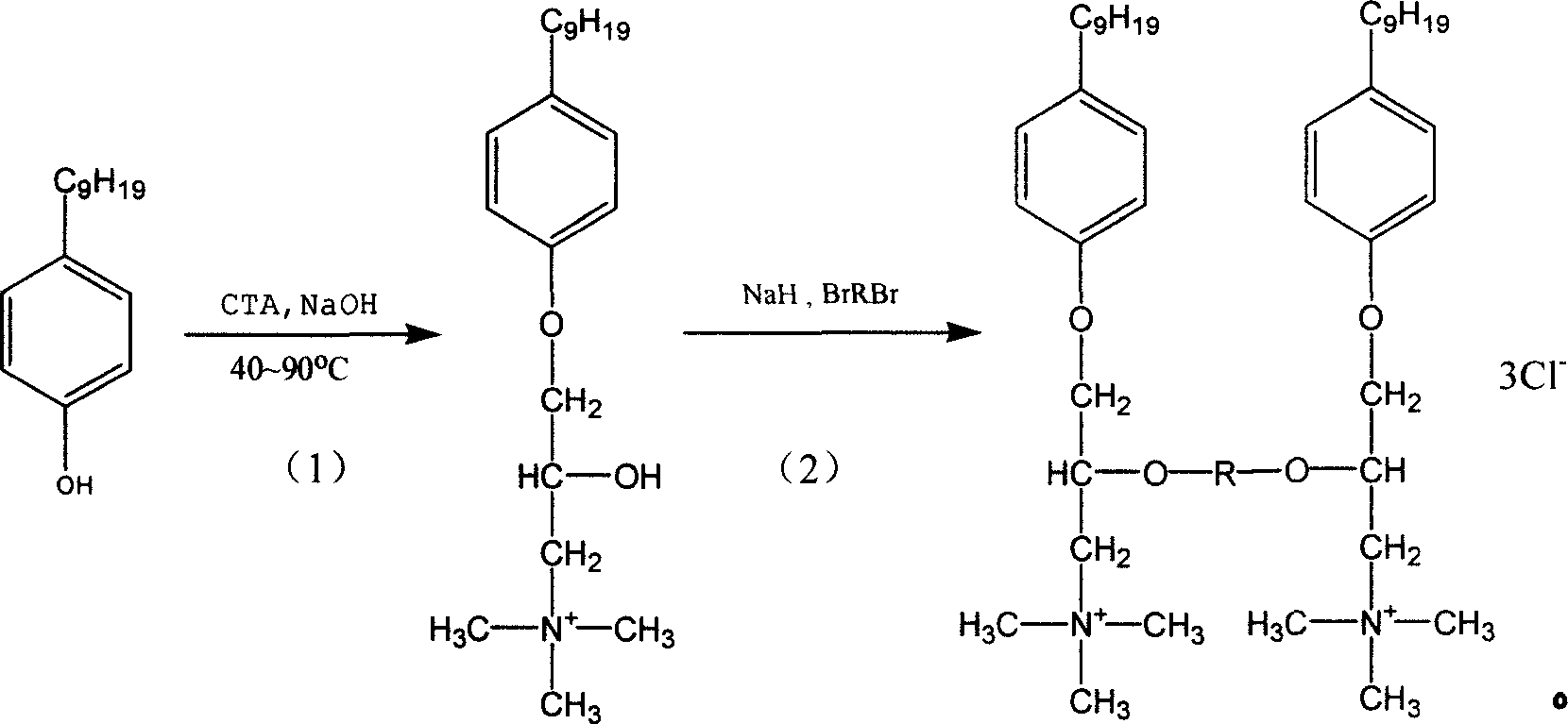

Method used

Image

Examples

Embodiment Construction

[0012] Add 22g (0.1mol) of p-nonylphenol, 4.4g (0.11mol) of sodium hydroxide and 50ml of isopropanol into a three-necked flask, heat to 50°C-60°C, stir with nitrogen for 1-2h, and slowly add 21g ( 0.11mol) of 3-chloro-2-hydroxypropyltrimethylammonium chloride, stirred for 2-3 hours, cooled to room temperature, filtered to remove inorganic matter, rinsed with isopropanol for 2-3 times, combined with the filtrate, and distilled The solvent was removed, recrystallized with acetone, and vacuum-dried to obtain NPQT as a light yellow solid powder.

[0013] Add 50ml of anhydrous ethylene glycol dimethyl ether and 7.5g (0.02mol) NPQT into the three-necked flask, cool down to below 10°C, slowly add 0.22mol60% NaH in several times (wash with anhydrous ether to remove oil), When the bubbles completely disappear, add 0.12mol dibromomethane ethylene glycol dimethyl ether solution, stir at room temperature for 2-3 hours, monitor the reaction process with HPLC, after the reaction is complete...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com