Production of copper or copper-alloy pipes

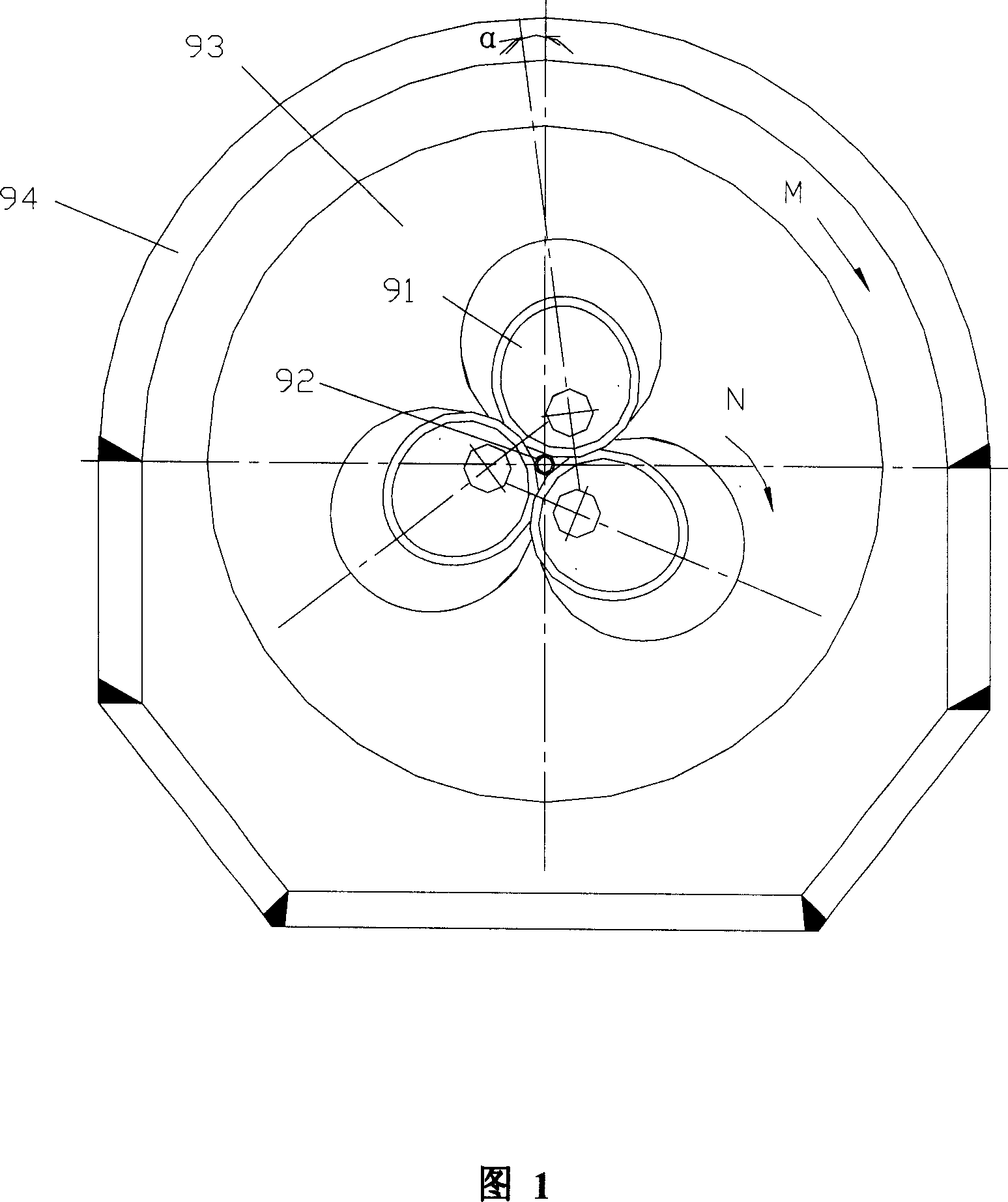

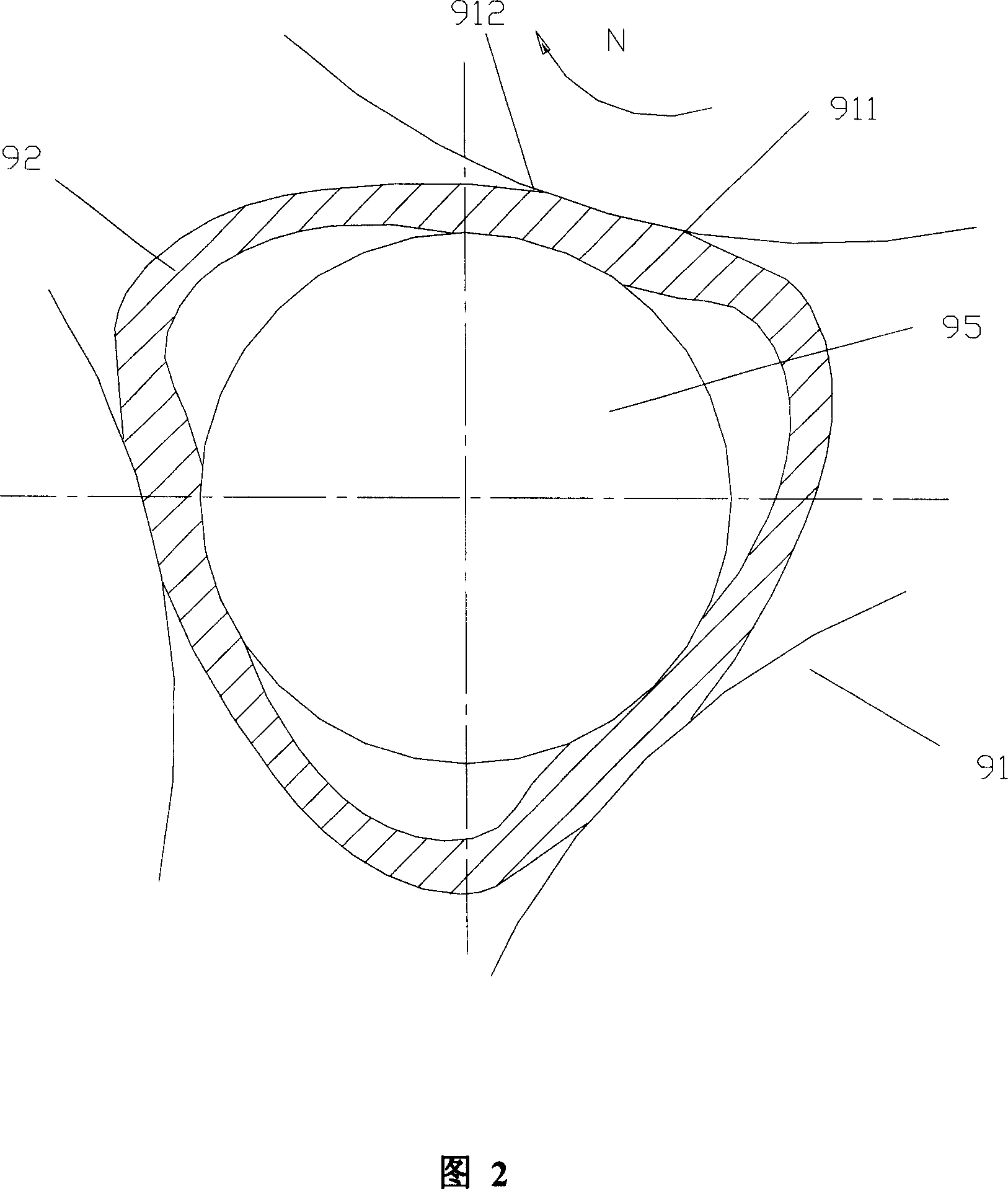

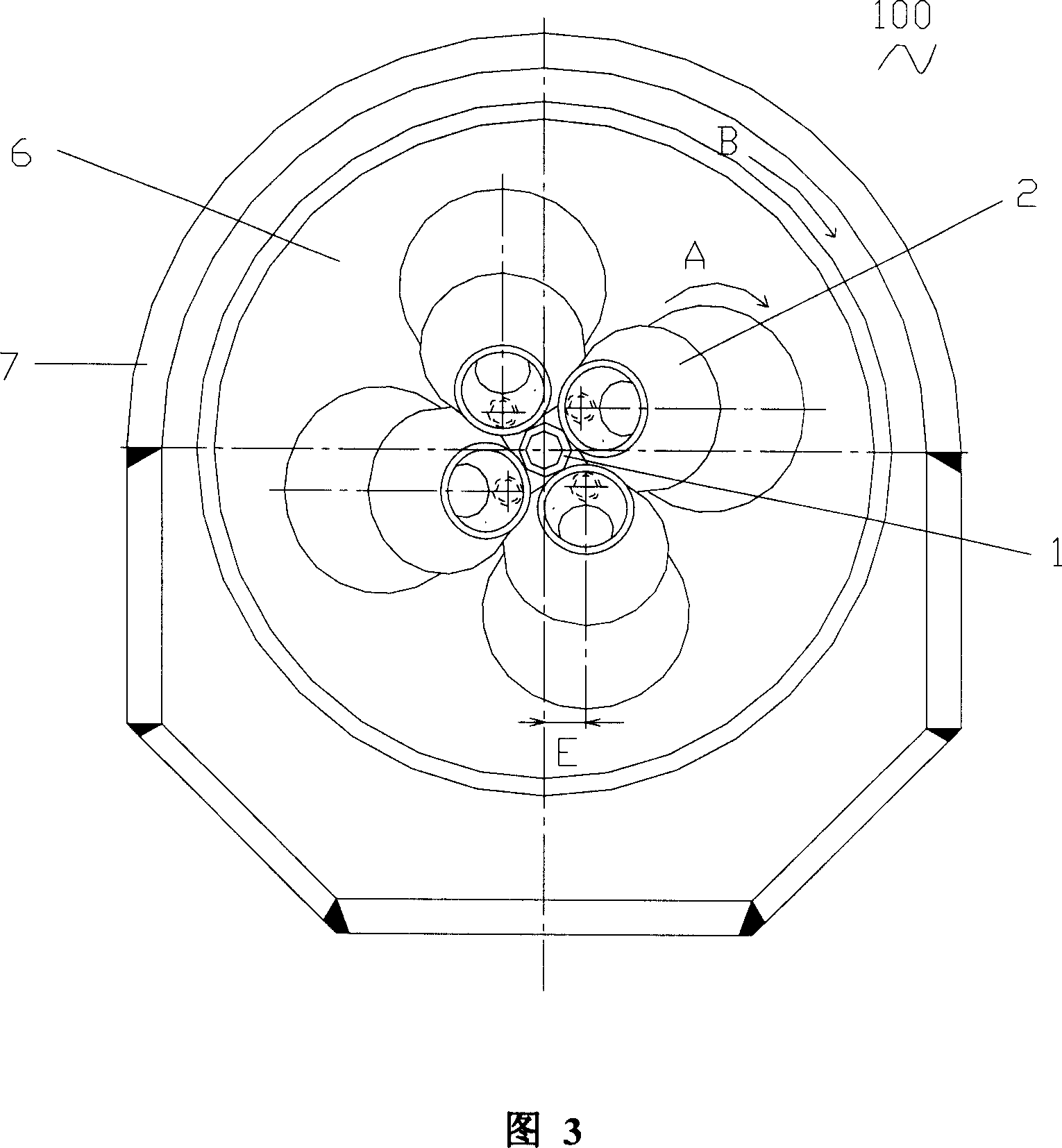

A manufacturing method and technology of copper alloy, applied in metal rolling, manufacturing tools, metal rolling and other directions, can solve the problems of large rolling resistance, low rolling speed, small rolling tube size, etc., and achieve faster recrystallization speed, The effect of improved wall thickness uniformity and reduced distortion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0047] Example 1: When the TP2 (a kind of phosphorus deoxidized copper) tube blank of 100 * 50mm is rolled by the above-mentioned four-roller planetary rolling mill 100, its rolled tube tube blank is φ 60 * 3 ± 0.15, and the rolling speed is 45m / min, the grain size is between 0.01--0.04mm, and after continuous pulling by four straight-drawing machines, the wall thickness uniformity is good, which is φ25×1±0.08mm.

example 2

[0048] Example 2: When the above-mentioned four-roller planetary rolling mill 100 is used to roll the TP2 tube billet of 180×30mm, the rolled tube billet is φ108×4.8±0.2, the rolling speed is about 45m / min, and the grain size is 0.010 Between --0.04mm, after four straight pulls, it is φ42×2.0±0.10mm.

example 3

[0049] Example 3: When the 180×30mm BFe10-1-1 tube blank (BFe10-1-1 iron white copper tube blank) is rolled by the above-mentioned four-roll planetary rolling mill 100, the rolled tube tube blank is φ108×5± 0.15, the rolling speed is about 45m / min, and the grain size is between 0.010--0.04mm. After four straight pulls, it is φ42×2.0±0.10mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| crystal size | aaaaa | aaaaa |

| crystal size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com