Epoxypropoxy end capped polyether and phenyl comodified polysiloxane, and preparation and use thereof

A glycidoxypropyl sealing and polysiloxane technology, which is applied in the fields of fine chemicals and new silicone materials, can solve the problems of insufficient cracking resistance, impact resistance and toughness, and limit wide application, and achieves broad application prospects, The effect of promoting industrial development

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

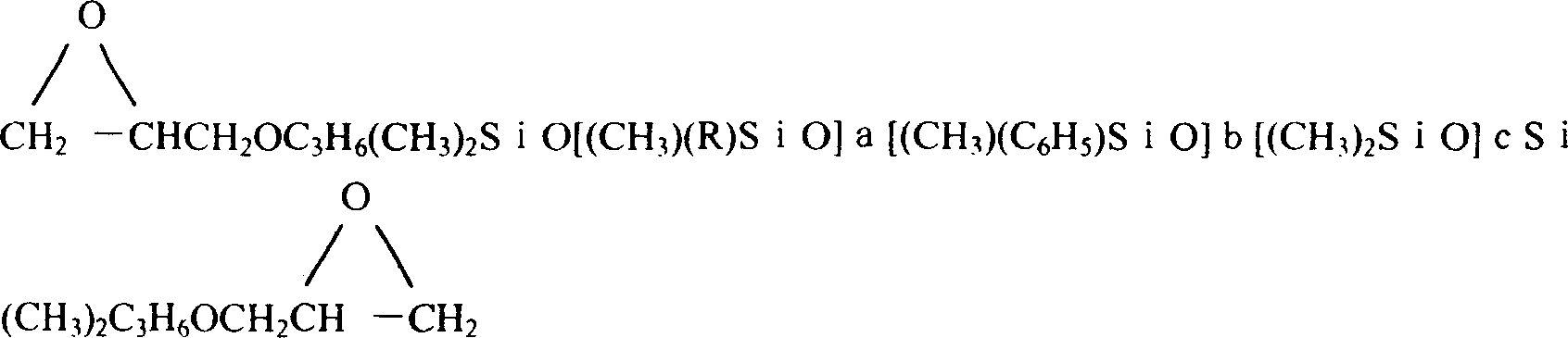

[0033] Embodiment 1, a kind of chemical substance of glycidoxypropyl-terminated polyether and phenyl co-modified polysiloxane, the structural formula of this substance is:

[0034]

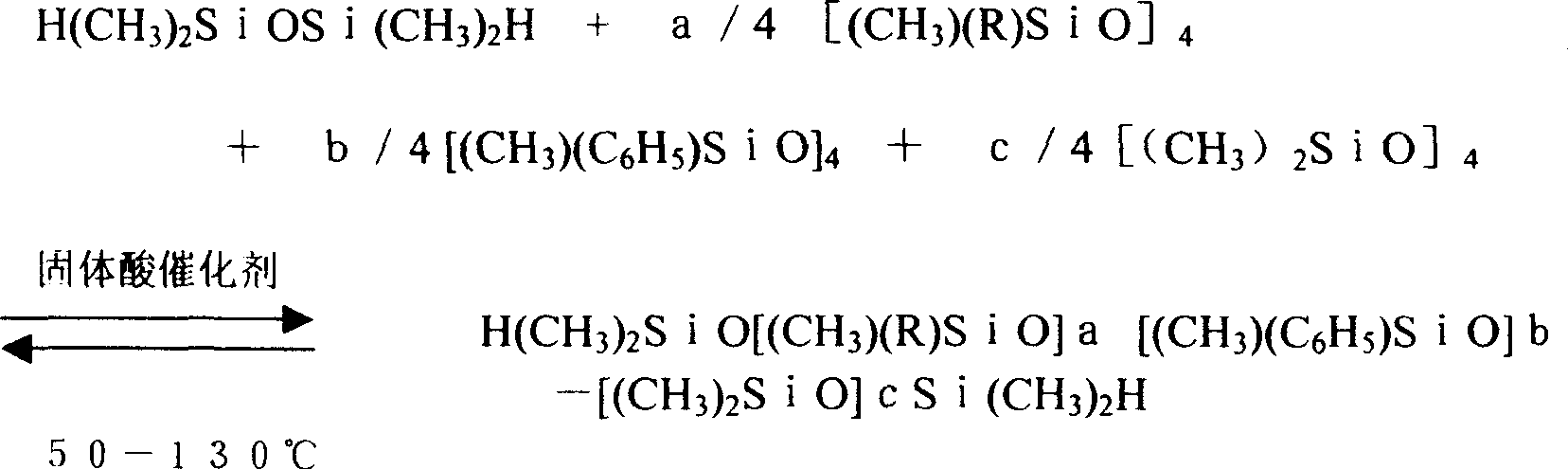

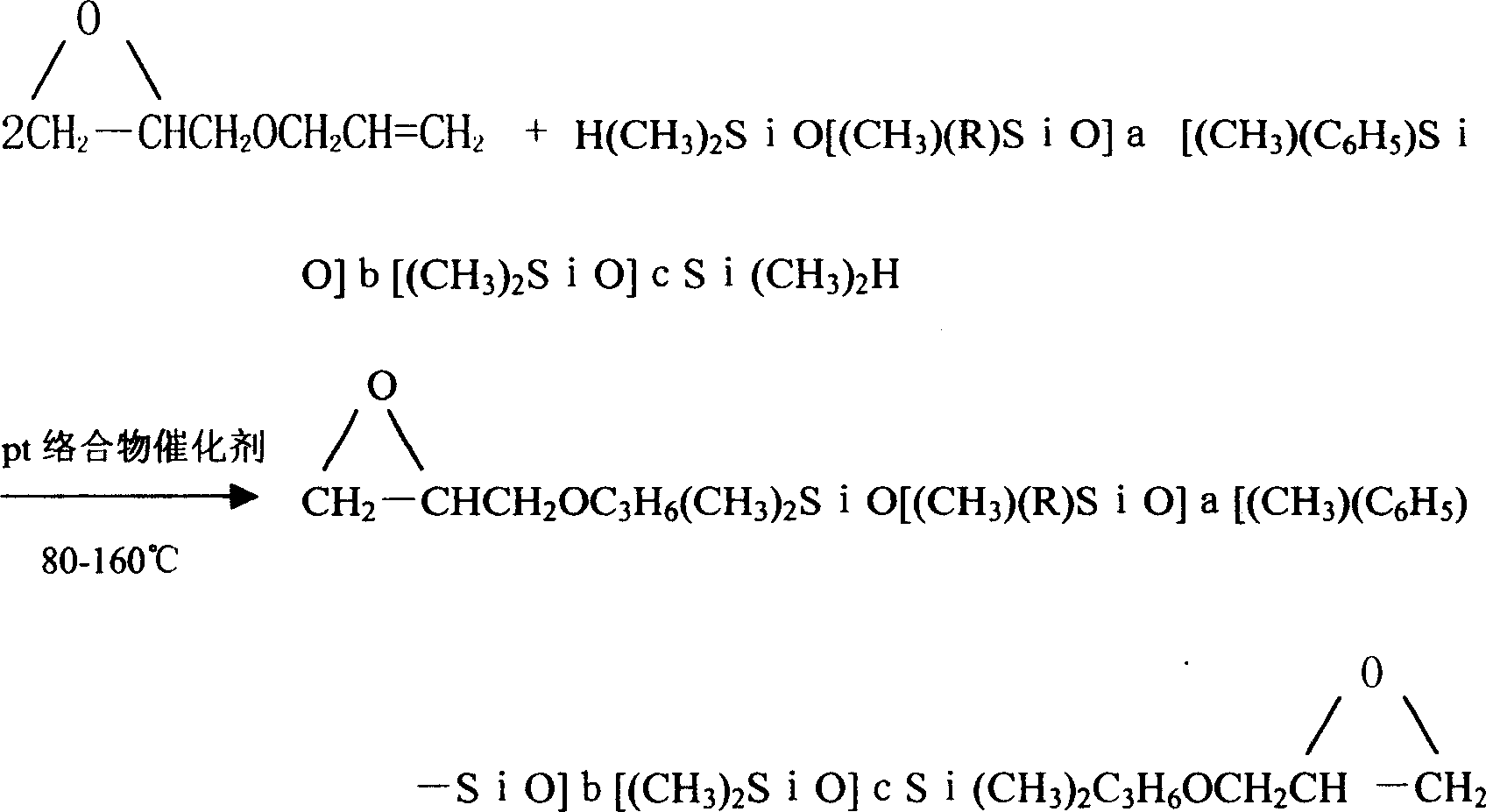

[0035] In the formula: R=-C 3 h 6 O(C 2 h 4 O) 3~10 (C 3 h 6 O) 3~10 CH 3 , a=2~3, b=2~3, c=2~3, the substance is prepared by the following method: first, tetramethylhydrogendisiloxane, methyl polyether siloxane tetracyclic body, methyl Phenylsiloxane tetracyclic body and octamethylcyclotetrasiloxane are measured according to the molar ratio in the chemical reaction equation, and then added into the reaction kettle in turn, start stirring, and add according to the amount of 1-10% of the total mass of the reactants Strongly acidic styrene resin catalyst, heat up to 50-130°C, keep stirring at normal pressure for 5-20 hours, then drop to below 50°C and filter to remove the catalyst, move the filtrate to a vacuum tank, and keep the temperature below 133Kpa at 100- Remove low-molecular subs...

Embodiment 2

[0041] Embodiment 2, a kind of preparation method of glycidoxypropyl end-capped polyether and phenyl co-modified polysiloxane, is first tetramethyl hydrogen disiloxane, methyl polyether siloxane four The cyclic body, methylphenylsiloxane tetracyclic body, and octamethylcyclotetrasiloxane are measured according to the molar ratio in the chemical reaction equation, and then added to the reactor in sequence, and the stirring is started. According to the total mass number of reactants 1- Add a strong acidic styrene resin catalyst in an amount of 10%, then raise the temperature to 50-130°C, keep stirring at normal pressure for 5-20 hours, then drop to below 50°C and filter to remove the catalyst, move the filtrate to a vacuum tank, and put it under a pressure of 133Kpa Remove the low molecular weight at 100-150°C for 3-10 hours at the following temperature to obtain the intermediate hydrogen-terminated polyether and phenyl co-modified siloxane. The low molecular weight can be reused...

Embodiment 3

[0047] Embodiment 3, a kind of preparation method of glycidoxypropyl end-capped polyether and phenyl co-modified polysiloxane, is first tetramethyl hydrogen disiloxane, methyl polyether siloxane four The cyclic body, methylphenylsiloxane tetracyclic body, and octamethylcyclotetrasiloxane are measured according to the molar ratio in the chemical reaction equation, and then added to the reactor in sequence, and the stirring is started. According to the total mass number of reactants 1- Add a strong acidic styrene resin catalyst in an amount of 10%, then raise the temperature to 50-130°C, keep stirring at normal pressure for 5-20 hours, then drop to below 50°C and filter to remove the catalyst, move the filtrate to a vacuum tank, and put it under a pressure of 133Kpa Remove the low molecular weight at 100-150°C for 3-10 hours at the following temperature to obtain the intermediate hydrogen-terminated polyether and phenyl co-modified siloxane. The low molecular weight can be reused...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com