Preparation of shrimp peptide powder

The technology of shrimp peptide protein powder and protease is applied in the field of preparation of feed protein source, which can solve the problems of low digestion and absorption rate, and achieve the effects of improving digestion and absorption rate, improving animal immunity and disease resistance, and reducing energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

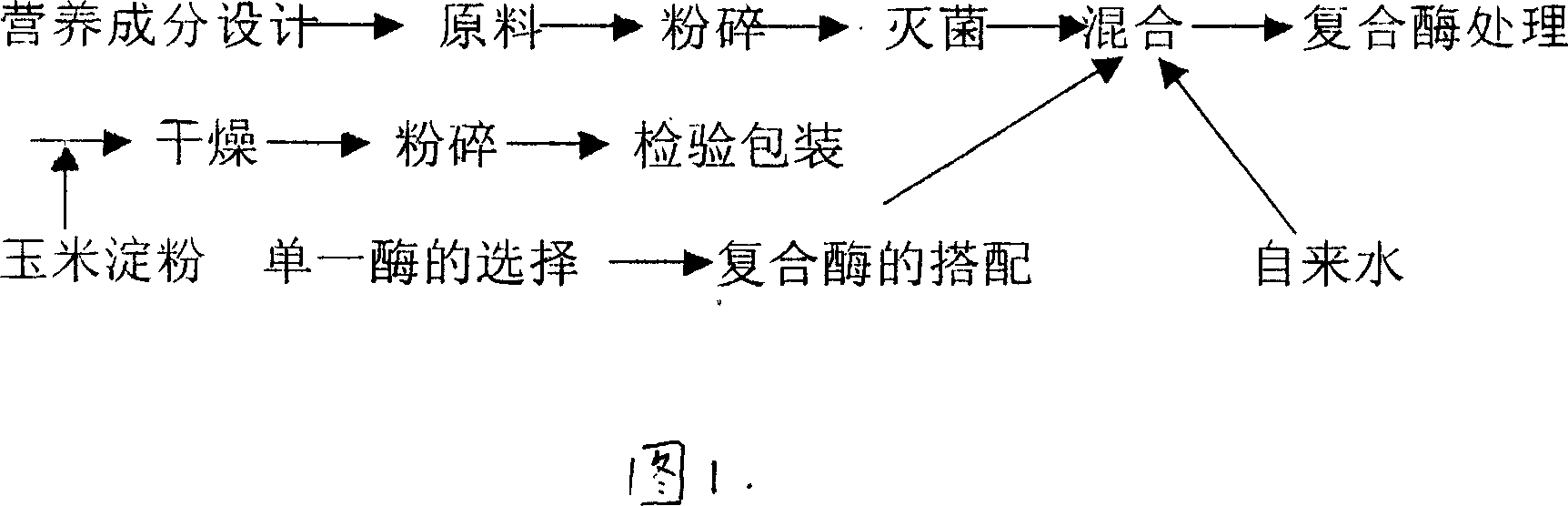

Method used

Image

Examples

Embodiment Construction

[0011] Take 1 ton of shrimp head to remove the shrimp skin, crush it into 60 meshes, and then carry out conventional sterilization treatment to obtain about 400 kilograms of raw materials for actual use. The raw materials, water and mixed enzyme are fully mixed in a ratio of 100:20:0.03 by weight Uniform, and control the temperature at 50-70°C for 40-50 hours of enzymolysis, then naturally cool to room temperature (not lower than 20°C), and obtain about 400 kg of a thick product after enzymolysis, and then add cornstarch 200 kg, placed in a dryer with a power of 300kw for about 6 to 8 hours of drying treatment, if the humidity is less than 30%, the drying treatment is qualified, and about 300 kg of dry matter is obtained, and then crushed at 60 to 80 mesh Crushing is carried out on the machine, and packaging is carried out after crushing. The mixed enzyme is a compound enzyme based on protease and acid cellulase, wherein the ratio of protease to acid cellulase is 70%: 30%, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com