Method of fabricating substrate with nano pattern, light emitting device and manufacturing method thereof

A technology of nanostructures and light-emitting devices, applied in semiconductor devices, electrical components, circuits, etc., can solve problems such as poor mass production capacity, high system cost, and low output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Preferred embodiments will be described in detail below with reference to the accompanying drawings.

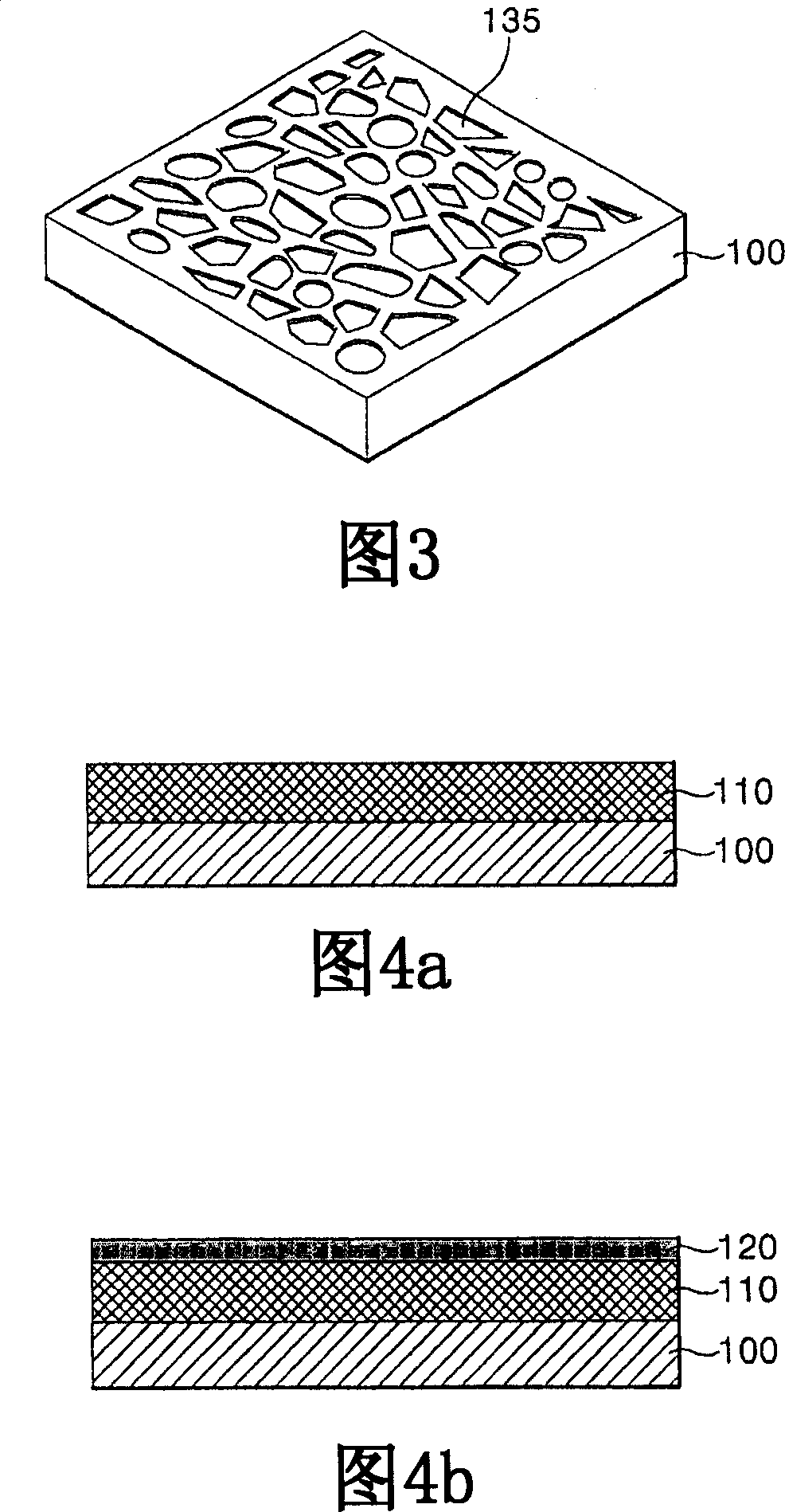

[0031] 2 is a schematic perspective view of an exemplary embodiment of a nanostructured substrate fabricated in accordance with the present invention, wherein the substrate (100) has a plurality of nanorods (105) formed on its top surface, and the plurality of The nanorods (105) include nanostructures.

[0032] The size of each nanorod (105) is 10 nm to 2000 nm, and although the nanorods are shown to be regular in FIG. 2, the nanorods may be arranged irregularly.

[0033] 3 is a schematic perspective view of another exemplary embodiment of a substrate formed with nanostructures manufactured according to the present invention, wherein the substrate (100) has a plurality of grooves (135) formed on its top surface, and the plurality of Each groove (135) is also nanostructured.

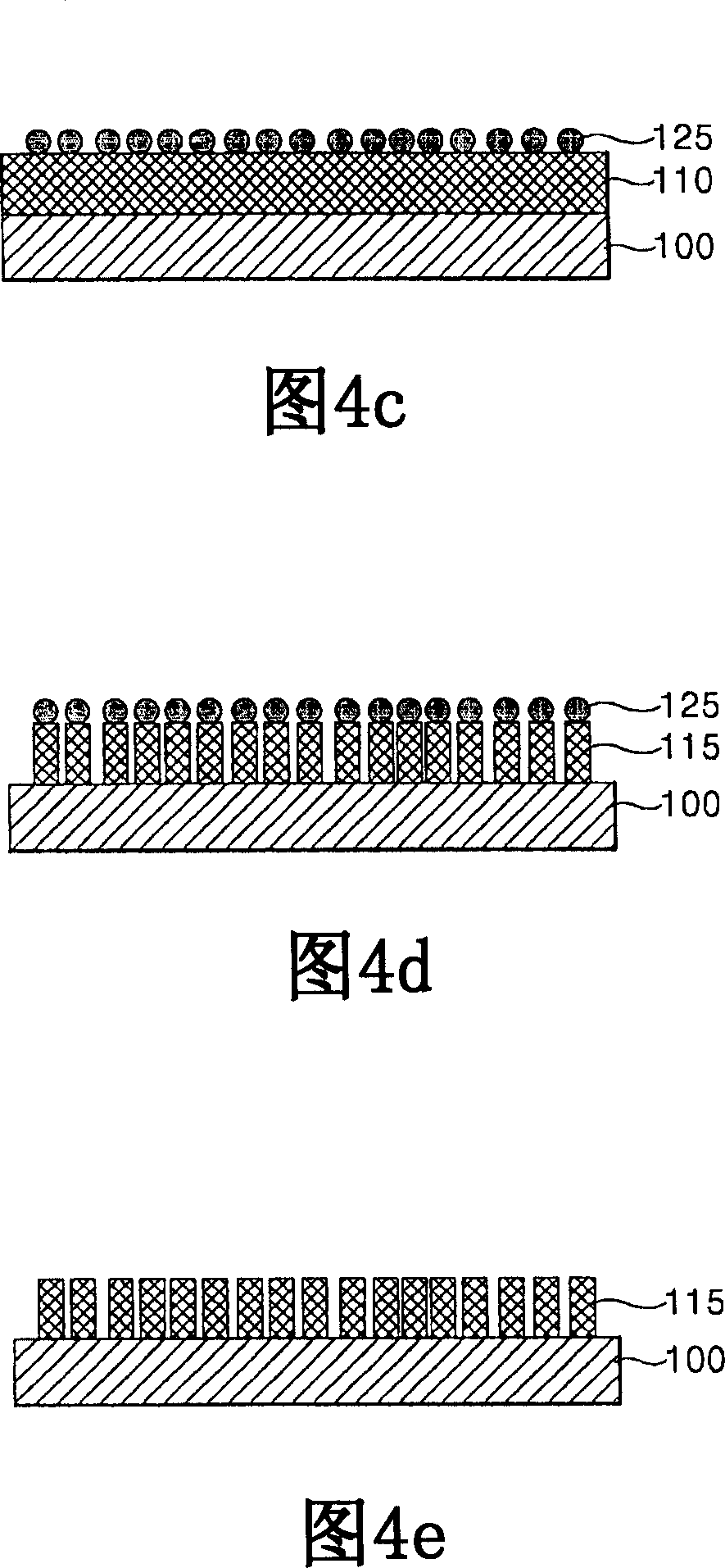

[0034] 4a-4g are cross-sectional views illustrating a method for manufacturing a substrate h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com