A mercury adsorbent composition, process of making same and method of separating mercury from fluids

A technology of composition and adsorbent, which is applied in the field of mercury adsorbent composition, preparation and separation of mercury from fluid, can solve problems such as inability to remove mercury, and achieve high mercury selectivity, high mercury loading capacity, and fast mercury removal speed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0135]High-efficiency mercury adsorbent products were prepared using natural diatomite products as raw materials. This raw material has a 5μm(d 10 , defined as the size of 10% of the volume smaller than the indicated size) to about 82 μm (d 90 , defined as the particle size distribution (PSD) where 90% of the volume by volume is smaller than the indicated size). To increase the surface silanol groups, 100 g of this material was hydrated by spraying 20 g of DI water in the mixer. In a 500 ml glass flask covered with a watch glass, 12.5 g of the hydrated material was mixed with 12.5 g of Silquest_A-189 gamma-mercaptopropyltrimethoxysilane, 225 ml of chloroform. After mixing on a magnetic stirrer at room temperature for 4 days, the slurry was washed with 62.5 ml of chloroform and filtered through a Buchner funnel with #2 Whatman filter paper. The separated solid was placed in a glass dish and air dried overnight.

Embodiment 2

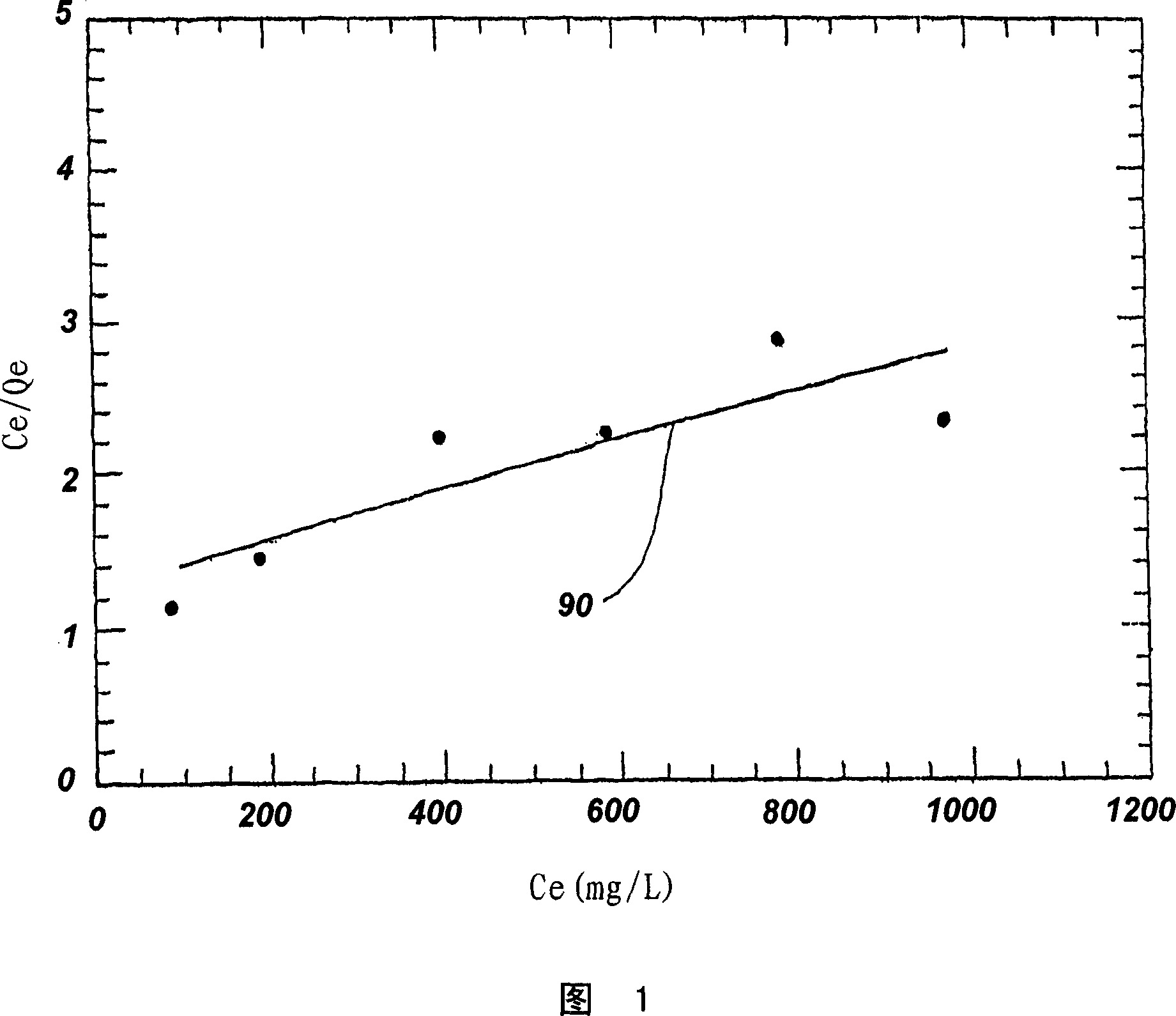

[0137] Mercury adsorption isotherm experiments were performed to study the mercury loading capacity. by HgCl 2 and DI water to prepare aqueous solutions containing 93, 137, 404, 591, 788 and 980 mg / L ionic mercury. 10 mg of the product of Example 1 were mixed with 50 ml of the mercury-containing solution in a 100 ml glass flask sealed with a packaging film. After mixing for 24 hours at room temperature on a magnetic stirrer, the solution was filtered through a 0.45 micron pore size filter. The filtrate was collected for measurement of mercury concentration using inductively coupled plasma (ICP). Mercury loading capacity was calculated from the difference in mercury concentration before and after adsorption. The highest mercury loading capacity was therefore calculated to be 428 mg Hg / g sorbent at 980 ppm.

[0138] Fitting isotherm data using Langmuir adsorption (Casey, 1997):

[0139] Q e =X m KC e / (1+KC e )

[0140] in:

[0141] Q e is the adsorption density at e...

Embodiment 3

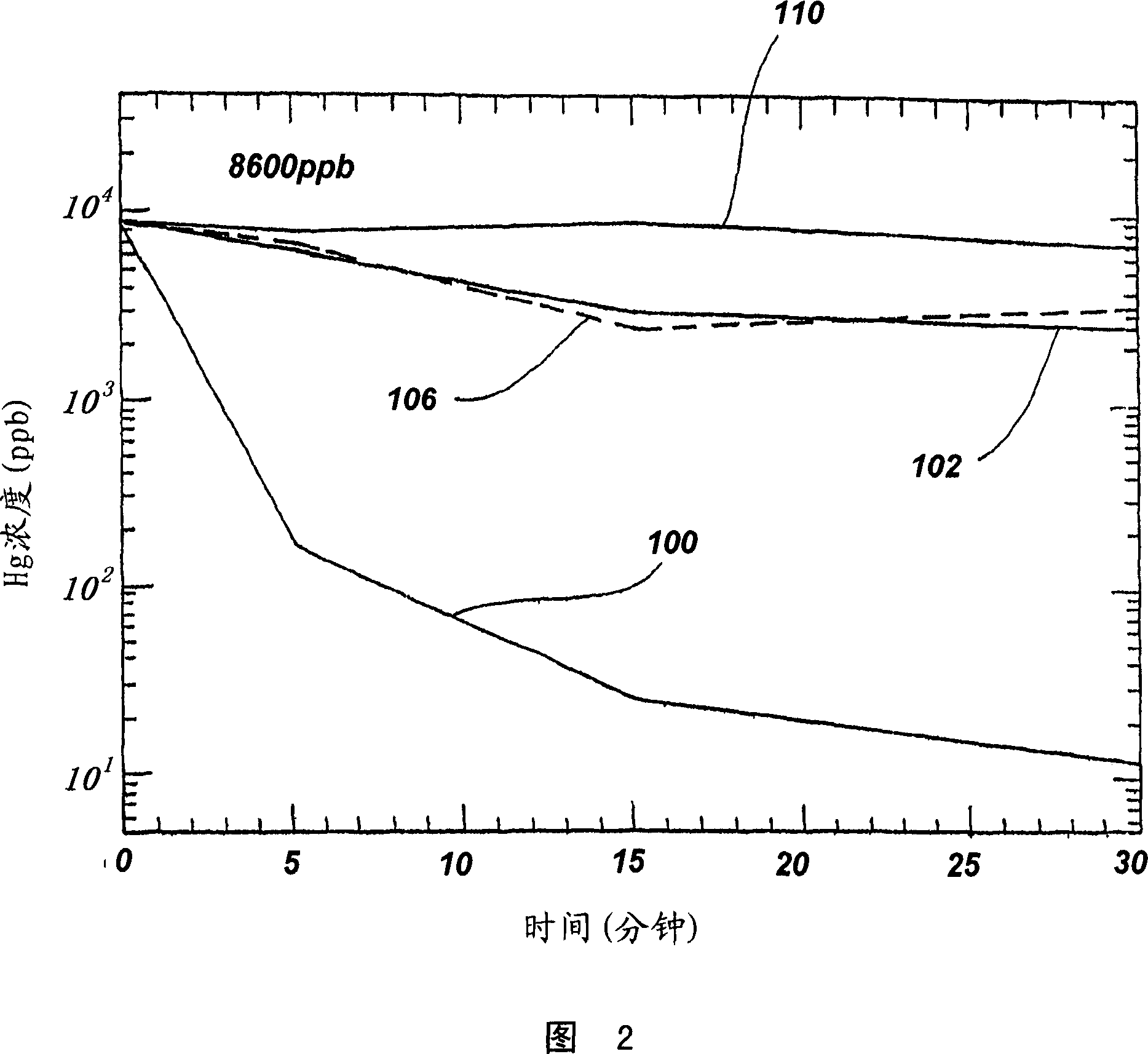

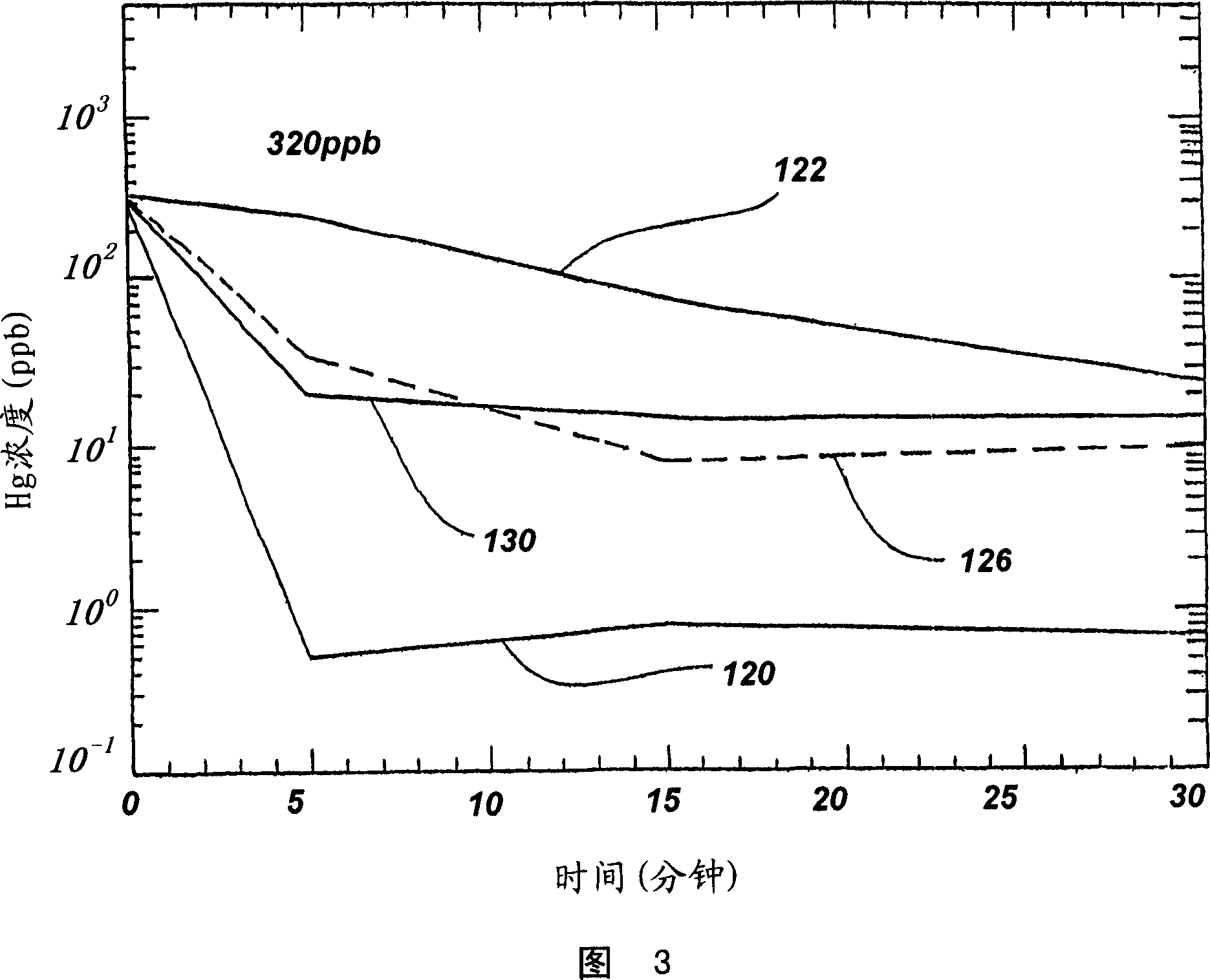

[0150] The mercury removal performance test of the product of Example 1 was carried out. 100 mg of the product of Example 1 was mixed with 100 ml of an aqueous solution containing 9700 ppb ionic mercury prepared from an atomic absorption (AA) standard solution. After mixing for 30 minutes at room temperature on a magnetic stirrer, the solution was filtered through a 0.45 micron pore size filter. The filtrate was collected for measurement of mercury concentration using cold vapor atomic adsorption (CVAA). The final mercury concentration was measured to be 7.4 ppb, ie a mercury removal rate of over 99.9% was obtained within 30 minutes at a load of 1 g / L.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| particle size distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com