Process for preparing fluorohalogenethers

A technology for fluorohalogenated hydrocarbons and fluorohalogenated olefins, which can be used in the preparation of ethers, the preparation of ethers by the addition of unsaturated compounds, and the preparation of dehalogenation, which can solve problems such as high loss of CFC112

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

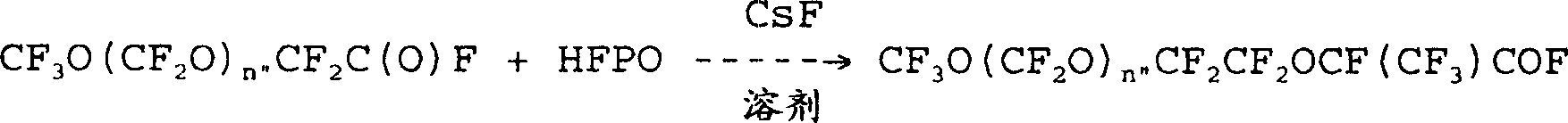

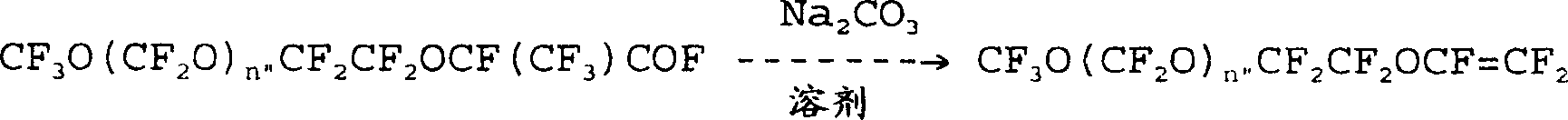

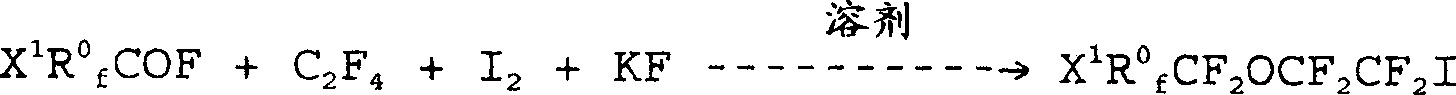

Method used

Image

Examples

Embodiment A

[0108] CF 3 Synthesis of OF

[0109] 10 l / h of gaseous fluorine, 5 l / h of CO and 10 l / h of nitrogen were allowed to flow simultaneously in an AISI 316 steel pipe (inner diameter 2.17 mm and length 100 mm). The reaction was initiated by heating the gas mixing zone at 100°C for several minutes. During the whole time, the reactor was cooled with air circulation so as to keep the temperature below 300°C; at the reactor outlet, the temperature was 250°C. Under these conditions, CO and F 2 Conversion to COF in greater than 95% yield (determined by IR analysis of effluent gas mixture) 2 .

[0110] Let the gas mixture, after cooling to 100°C, flow through a catalyst bed consisting of 300g of finely ground anhydrous CsF with a particle size less than or equal to 0.1mm, and 300g of acicular copper with a diameter of 0.2mm and a length of 6 to 7mm. Mix composition. The catalyst was put into a tubular reactor (inner diameter 55 mm, length 250 mm). The reaction temperature in gas wa...

Embodiment 1

[0112] Addition of fluorine to trichloroethylene

[0113] By 25.5g trichlorethylene (TCE) and 475g CF 3 O-CFCl-CF 2 The solution consisting of the Cl reaction solvent was introduced into a 400cc AISI 316 reactor equipped with a mechanical stirrer.

[0114] The solution was cooled by a cryostat to maintain a temperature of -70°C, and under stirring, 1 mole of fluorine was diluted with nitrogen at a molar ratio of 1 / 2 and sent through the bubbler inlet. Simultaneously, 1.07 mol TCE was fed by the pump. These reactants were fed over 8 h, during which time the temperature was maintained at -70°C.

[0115] At the end of the reaction, 633 g of solution were withdrawn and analyzed by GC / MS (Gas Chromatography-Mass Spectrometry). The conversion of TCE is equal to 75%, producing CFC 122a (CHClF-CCl 2 The selectivity of F) is 56.7%.

Embodiment 2

[0117] The CFC 122a obtained in Example 1 (CHClF-CCl 2 F) Dehydrochlorination

[0118] 90 g of CFC 122a with a purity of 94% obtained in Example 1, 5 g of tetrabutylammonium hydroxide were introduced into a 250 mL four-neck reactor equipped with a magnetic stirrer, dropping funnel, thermometer and water condenser. A 20% aqueous solution of 26 g NaOH was added under stirring, and the heat of reaction was controlled at 30° C. using water and an ice bath. When the base addition was complete, the mixture was allowed to stir for an additional 40 min at 30°C. It was cooled to 10°C: the final mixture showed 2 separated phases. The reaction mixture was poured into a separatory funnel maintained at 10 °C. 72 g of an organic phase with a higher density, consisting of the compound (65 g) CFC 1112 (FCCl=CCIF), with a purity of 99%, were isolated. The conversion rate is 100%, and the yield is 98%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com