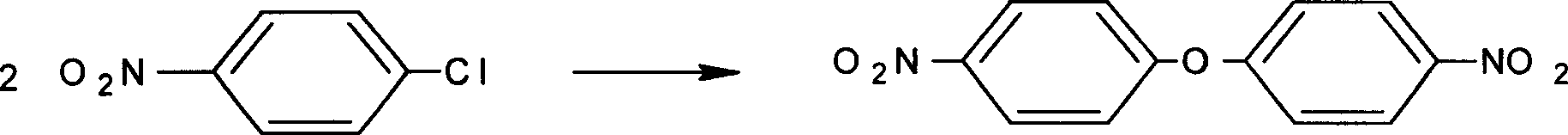

Preparing process of 4,4-dinitro diphenyl ether

A technology of dinitrodiphenyl ether and p-nitrochlorobenzene, which is applied in 4 fields, can solve the problems of large environmental pollution, large environmental pollution, complicated post-processing, etc., and achieves low environmental pollution, good product quality and low production cost. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Put 15.75Kg of p-nitrochlorobenzene, 860g of sodium benzoate, 6Kg of sodium carbonate and 10L of N-methylpyrrolidone into a 500L reactor with stirring device, and heat up to 190-210°C by passing steam into the interlayer of the reactor , the condensation reaction proceeds under the conditions. The reaction was finished after 8 hours, and the N-methylpyrrolidone solvent was distilled off. Cool to 85°C, add 300L of distilled water, precipitate the product, centrifuge and dry to obtain 11.0Kg of 4,4'-dinitrodiphenyl ether, yield 85.0%, melting point 143.2-144.3°C, content 99.5% (HPLC).

Embodiment 2

[0025] Other conditions are the same as in Example 1, and the solvent is recycled N-methylpyrrolidone. 11.6Kg of 4,4'-dinitrodiphenyl ether was obtained, with a yield of 89.6%, a melting point of 142.8-144.0°C, and a content of 99.3% (HPLC).

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com