Graphite/metal powder in core-shell structure and its preparing method

A metal core-shell structure technology, applied in chemical instruments and methods, inorganic pigment treatment, fibrous fillers, etc., can solve problems such as corrosion, difficulty in obtaining uniformly dispersed core/shell structure powder, complex process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

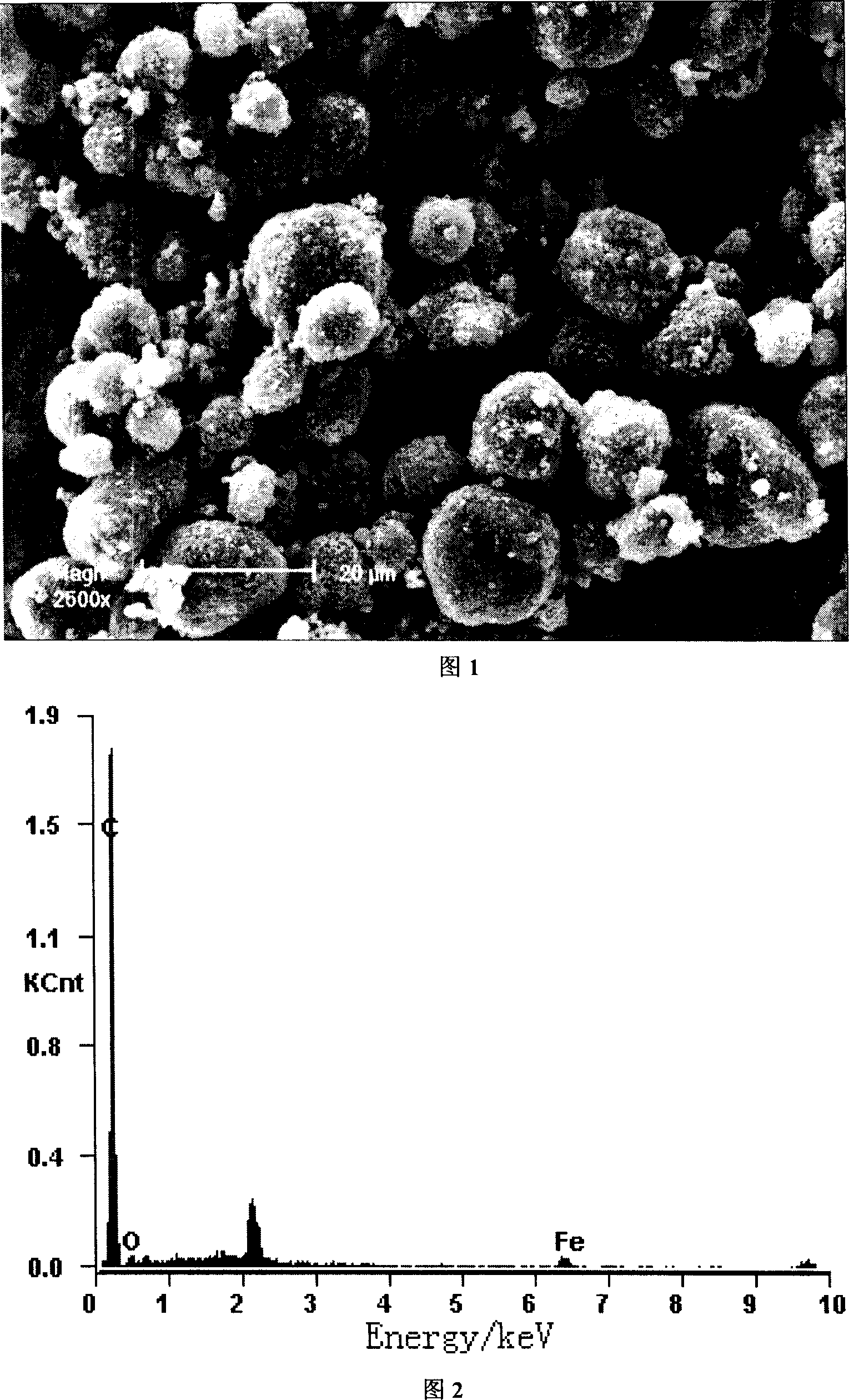

[0039] Example 1: Graphite / iron core / shell structure powder material with core / shell mass ratio of 1:1

[0040] Prepare 1.786L ferric sulfate solution A with a concentration of 0.5M and ammonium bicarbonate solution B with a concentration of 1.0M, and 10L suspension mother liquor C. The graphite particle content in the suspension mother liquor C is 5g / L, and the polyethylene glycol content is 2mL / L . Pass A and B into C under mechanical stirring at the same time to form a mixed solution D, adjust the flow rate of A to 1mL / L, adjust the flow rate of B to control the pH value at 6.5, and the preparation process involves the reactions of formulas (1) and (3).

[0041] After feeding, the mixed solution D was subjected to solid-liquid separation and repeated washing, and then the obtained filter cake was dried at 60° C. for 12 hours to obtain graphite / iron core / shell precursor powder.

[0042] Precursor powder in N 2 / H 2 Reduction in mixed gas at 800°C for 2 hours, H 2 The flo...

Embodiment 2

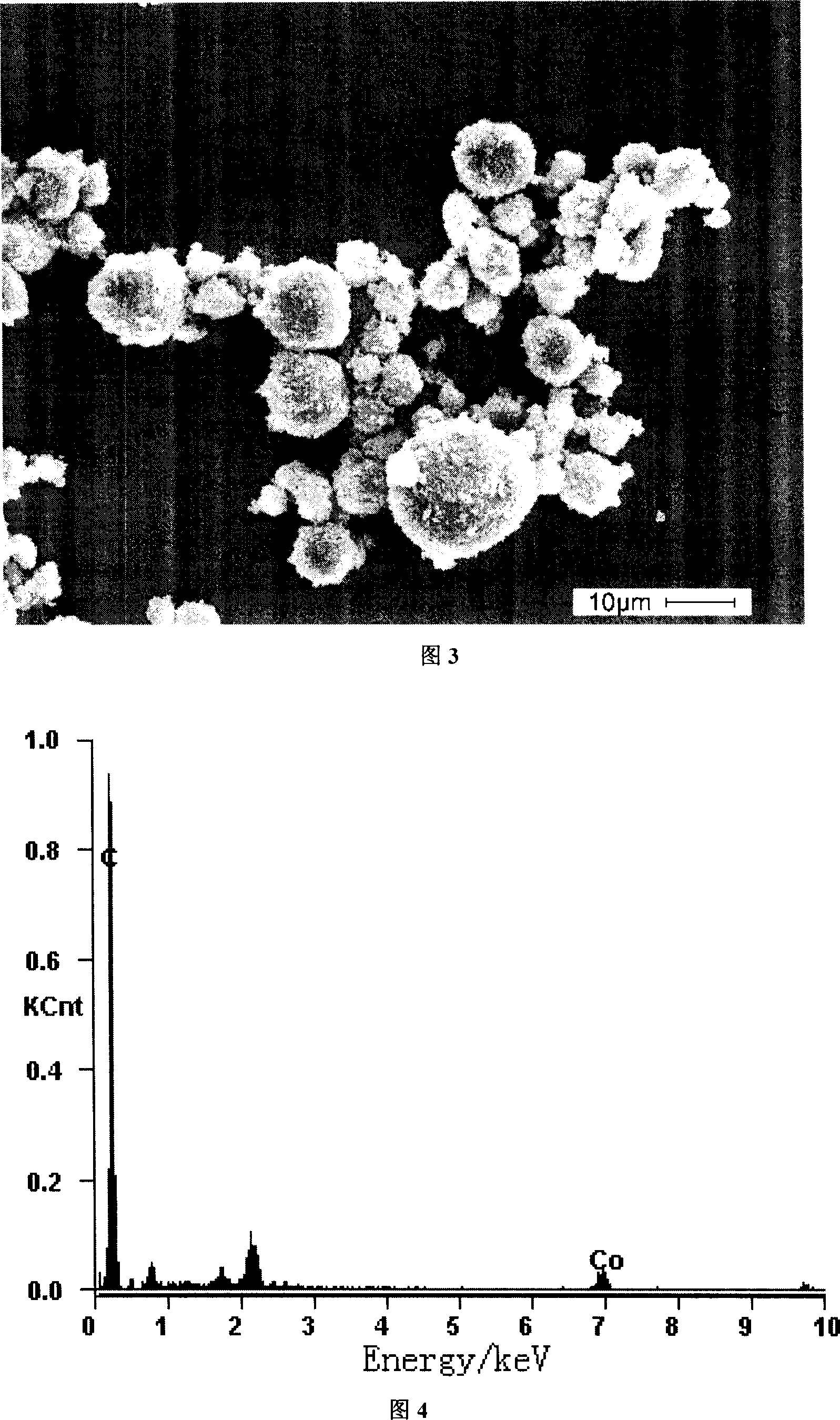

[0043] Example 2: Graphite / cobalt core / shell structure powder material with a core / shell mass ratio of 1:0.5

[0044] Prepare 3.178L of 0.2M cobalt nitrate solution A and 0.4M ammonium bicarbonate solution B, and 5L suspension mother solution C respectively, with graphite particle content of 15g / L and polypropylene alcohol content of 5mL / L. Pass A and B simultaneously into C under mechanical stirring to mix solution D, adjust the flow rate of A to 2.5mL / L, adjust the flow rate of B to control the pH value at 8.0, and the preparation process involves the reaction of formula (4).

[0045] After feeding, the mixed solution D was subjected to solid-liquid separation and repeated washing, and then the obtained filter cake was dried at 80° C. for 10 h to obtain a graphite / cobalt core / shell precursor powder.

[0046] Precursor powder in N 2 / H 2 Reduction in mixed gas at 600°C for 2 hours, H 2 The flow rate is 40mL / min, N 2 The flow rate is 160mL / min, and graphite / cobalt core / she...

Embodiment 3

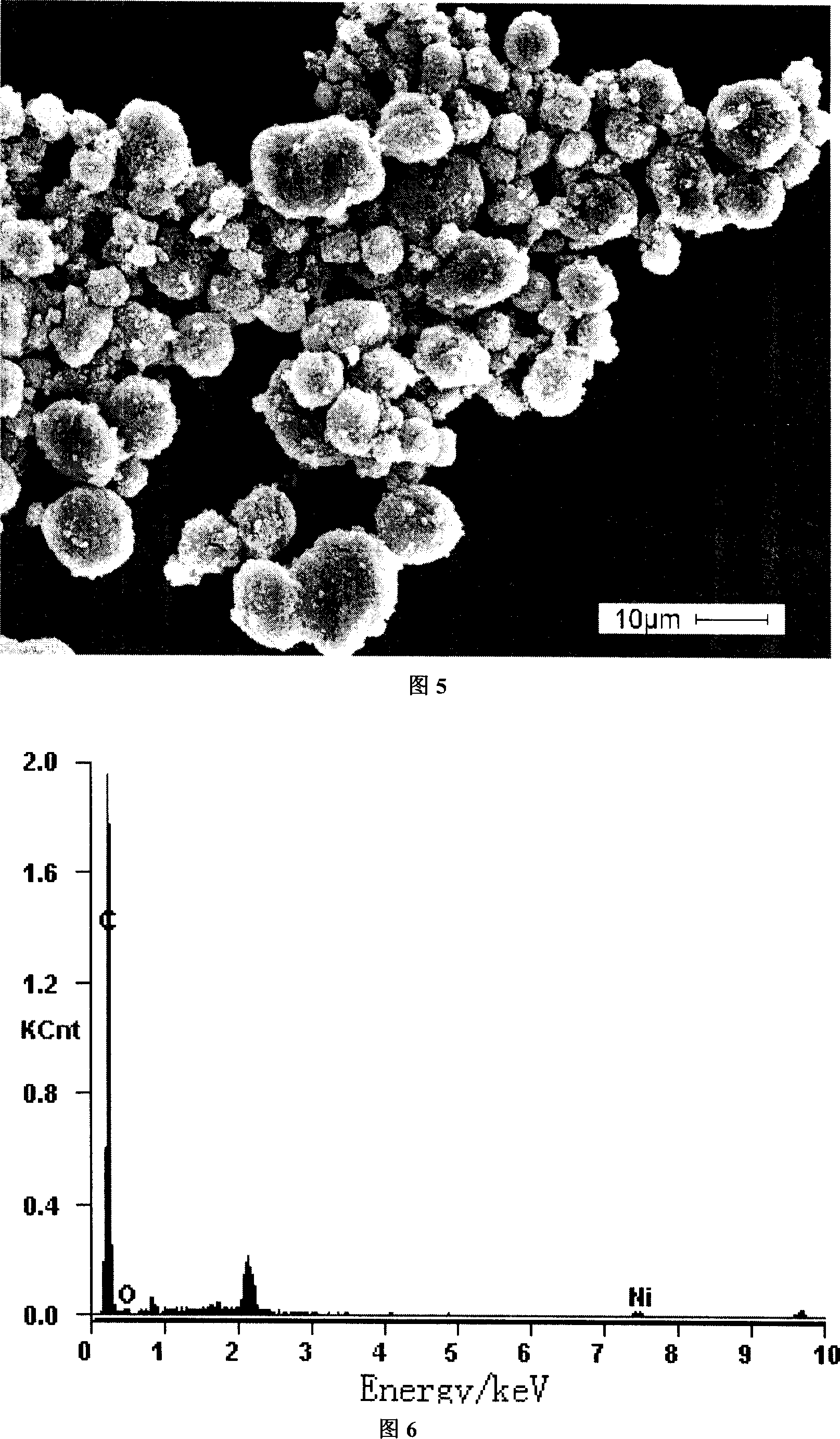

[0047] Embodiment three: the graphite / nickel core / shell structure powder material with a core / shell mass ratio of 1:0.2

[0048] Prepare 4.310L concentration of 0.1M nickel sulfate solution A and 0.2M ammonium bicarbonate solution B, and 5L suspension mother liquor C respectively, the content of graphite particles is 25g / L, and the content of polyethylene glycol is 7.5mL / L. Pass A and B simultaneously into C under mechanical stirring to mix solution D, adjust the flow rate of A to 10mL / L, adjust the flow rate of B to control the pH value at 9.0, and the preparation process involves the reaction of formula (6).

[0049] After feeding, the mixed solution D was subjected to solid-liquid separation and repeated washing, and then the obtained filter cake was dried at 60° C. for 12 hours to obtain graphite / iron-nickel core / shell precursor powder.

[0050] Precursor powder in N 2 / H 2 Reduction in mixed gas at 500°C for 1 hour, H 2 The flow rate is 20mL / min, N 2 The flow rate is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com