Dynamic photon crystal producing method

A technology of photonic crystals and production methods, applied in crystal growth, single crystal growth, chemical instruments and methods, etc., can solve the problems of reducing the difficulty of experiments and making them difficult, and achieve the effect of reducing the difficulty of experiments and making experiments flexible and easy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

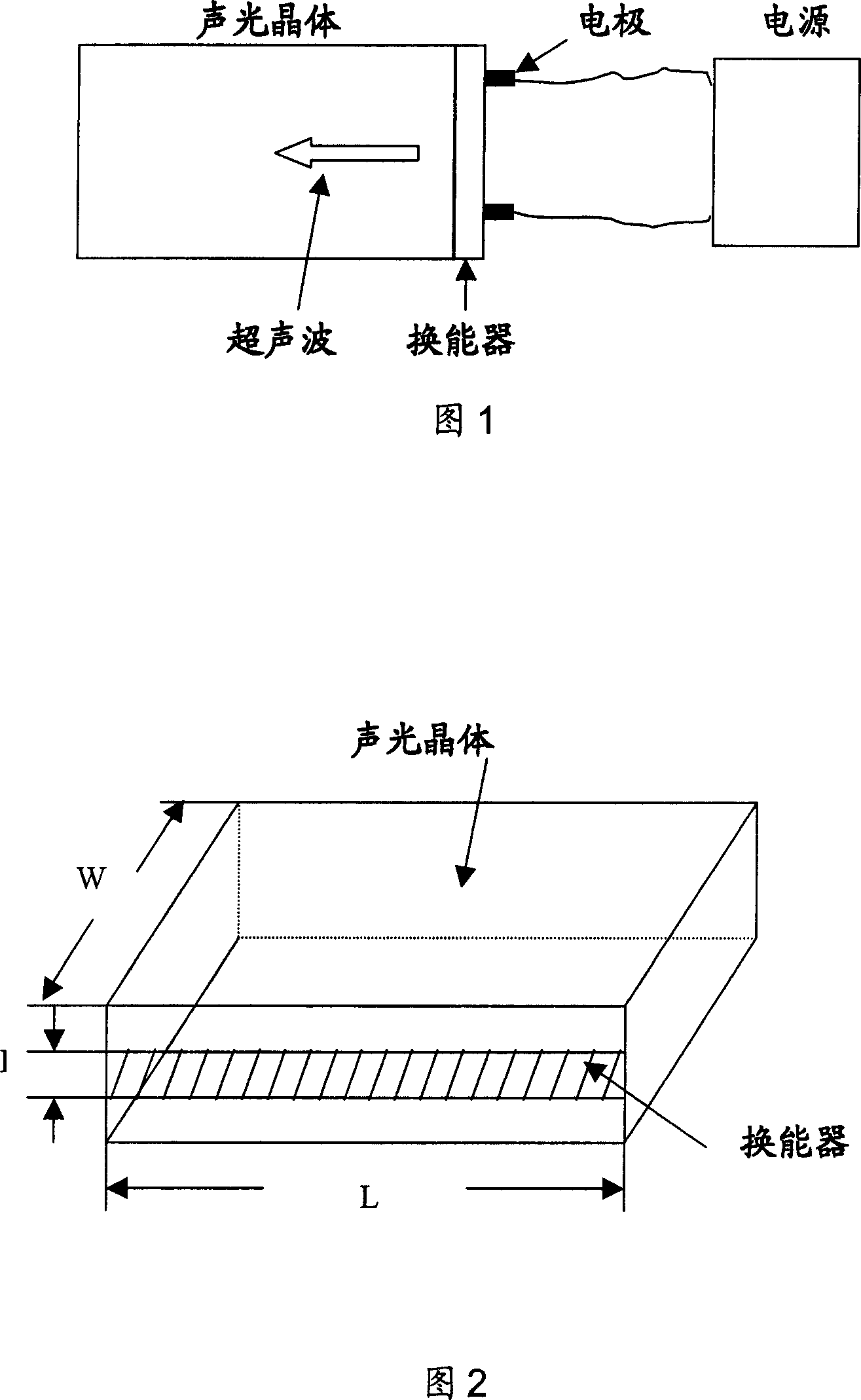

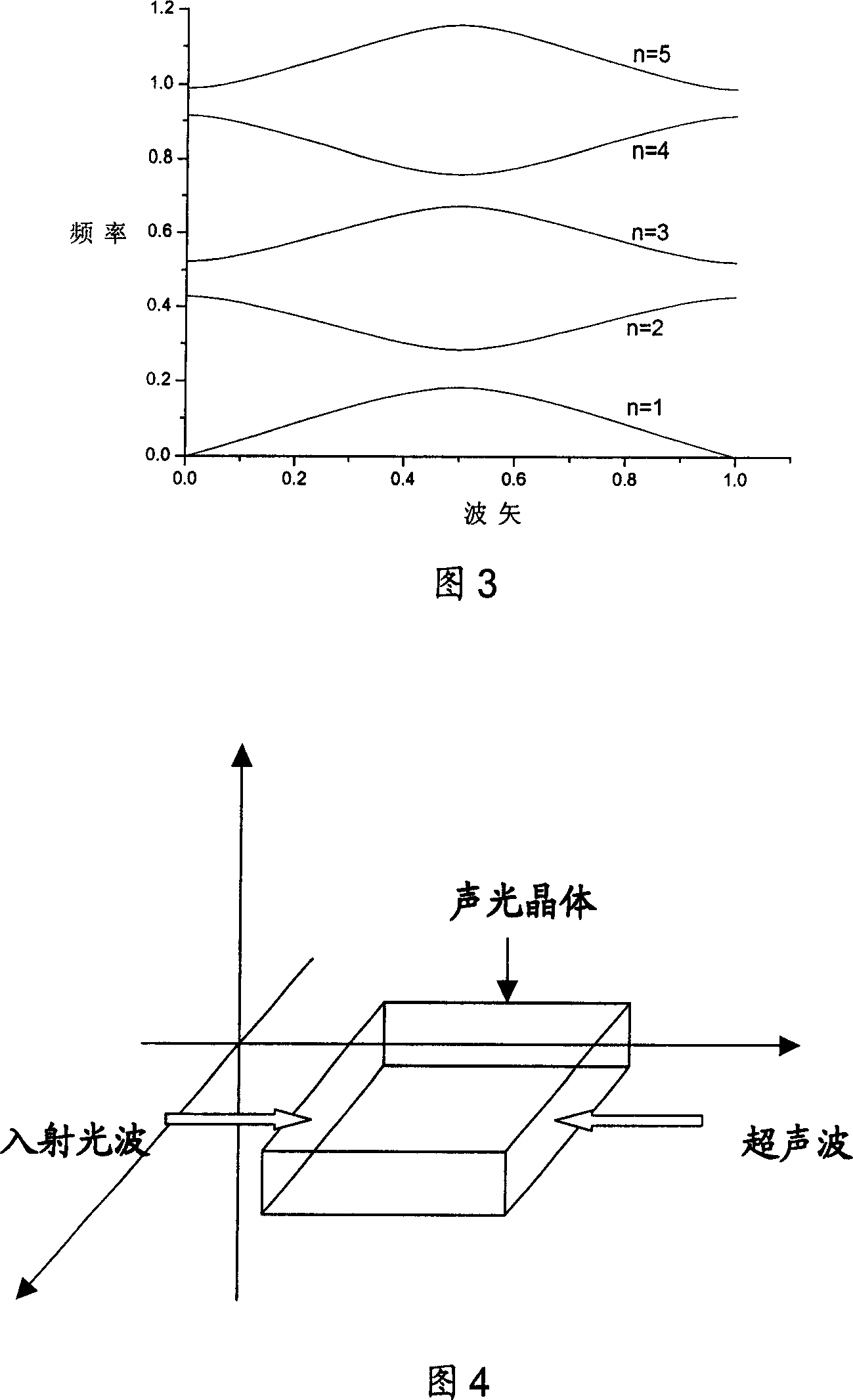

[0029] Embodiment 1 is to use the present invention to make tellurium oxide photonic crystals. Selected tellurium oxide crystal refractive index n 0 =2.26, sound and light merit value M 2 =1200×10 -15 the s 3 / kg, the photonic bandgap of the acousto-optic crystal is proportional to the acousto-optic figure of merit of the acousto-optic crystal, so the crystal with a large acousto-optic figure of merit is selected in the experiment to facilitate the increase of the width of the photonic bandgap. First, the tellurium oxide crystal is polished and oriented, and bonded with the polished piezoelectric transducer, and then the bonded piezoelectric transducer is thinned by mechanical grinding. Plating electrodes on the piezoelectric transducer, the area of the electrodes is 0.25mm 2 , the photonic bandgap of the acousto-optic crystal is inversely proportional to the area of the piezoelectric transducer. In the experiment, the area of the piezoelectric transducer was minimiz...

Embodiment 2

[0030] Embodiment 2 utilizes the present invention to make lead molybdate photonic crystal. Selected lead molybdate crystal refractive index n 0 =2.26, sound and light merit value M 2 =36.3×10 -15 the s3 / kg, the photonic bandgap of the acousto-optic crystal is proportional to the acousto-optic figure of merit of the acousto-optic crystal, so the crystal with a large acousto-optic figure of merit is selected in the experiment to facilitate the increase of the width of the photonic bandgap. First, the lead molybdate crystal is polished and oriented, and bonded with the polished piezoelectric transducer, and then the bonded piezoelectric transducer is thinned by mechanical grinding. Plating electrodes on the piezoelectric transducer, the area of the electrodes is 0.5mm 2 , the photonic bandgap of the acousto-optic crystal is inversely proportional to the area of the piezoelectric transducer. In the experiment, the area of the piezoelectric transducer was minimized to in...

Embodiment 3

[0032] Embodiment 3 is the modulation of ultrasonic waves on tellurium oxide crystals. Selected tellurium oxide crystal refractive index n 0 =2.26, sound and light merit value M 2 =1200×10 -15 the s 3 / kg. First, the tellurium oxide crystal is polished and oriented, and bonded with the polished piezoelectric transducer, then the bonded piezoelectric transducer is thinned by mechanical grinding, and the electrodes are plated on the piezoelectric transducer On the top, the piezoelectric transducer is connected to the high-frequency driving power supply through the electrodes. When the incident light wavelength λ 0 =0.633μm, the selected incident light wavelength should be in the visible light range as far as possible, so as to facilitate the experimental operation. Adjust the electric power and frequency of the high-frequency drive power supply, when the sound and light merit value M 2 =1200×10 -15 the s 3 / kg, the ultrasonic velocity in the tellurium oxide crystal is V...

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com