Method for black liquor treatment

A treatment method and black liquor technology, which are applied in the regeneration of lye and the recycling of pulp by-products, etc., can solve the problems of high treatment cost, leakage of odorous substances, and large equipment cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

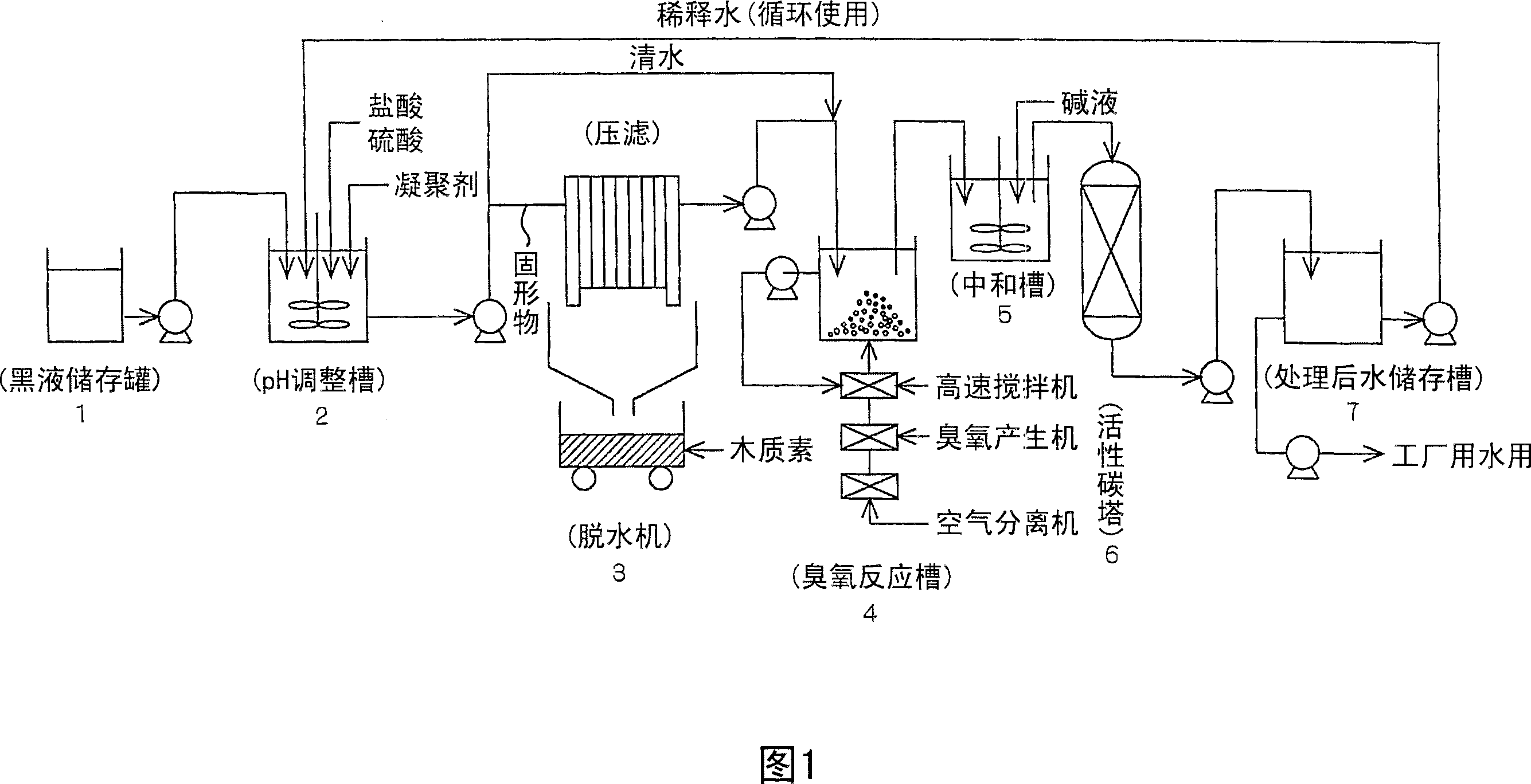

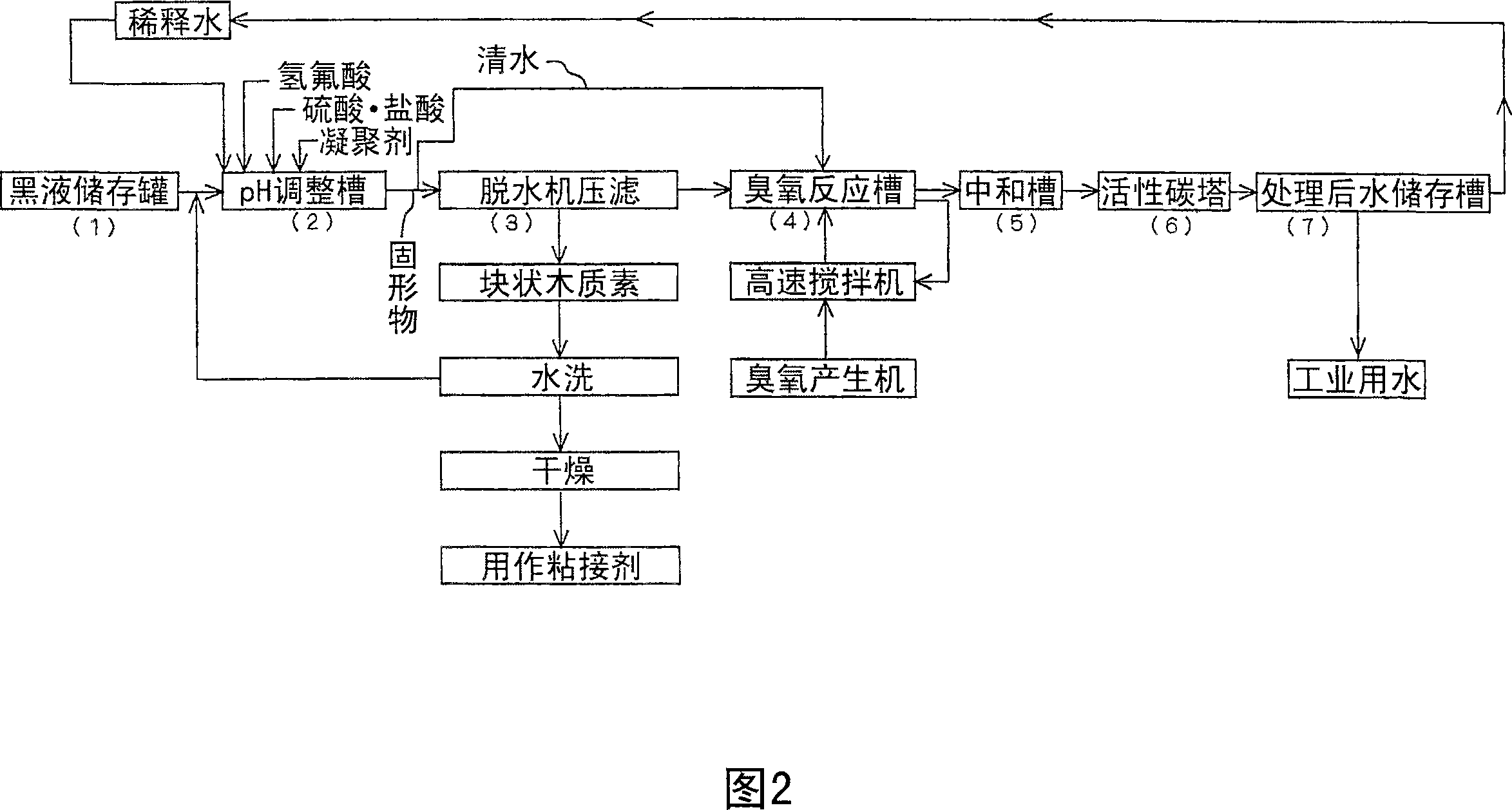

[0031] FIG. 1 shows a system configuration diagram of the embodiment, and FIG. 2 shows its flowchart.

[0032] First, in Fig. 1, the number 1 from the left is a black liquor storage tank, in which black liquor is stored.

[0033] Next, reference number 2 is a pH adjustment tank, in which black liquor and dilution water are filled, acids such as hydrochloric acid and sulfuric acid are added, and a coagulant is added and slowly stirred to deposit lignin and other substances. At this time, it is desirable to add a trace amount of hydrofluoric acid as an acid.

[0034] Subsequently, reference numeral 3 is a dehydrator 3 in which lignin is taken out as a solid by, for example, pressure filtration.

[0035] Reference numeral 4 is an ozone reaction tank, and a liquid from which lignin has been removed by pressure filtration is introduced, and ozone is used as microbubbles to perform a contact reaction.

[0036] At this stage, since ozone gas, which is a powerful oxidizing species, ...

Embodiment 2

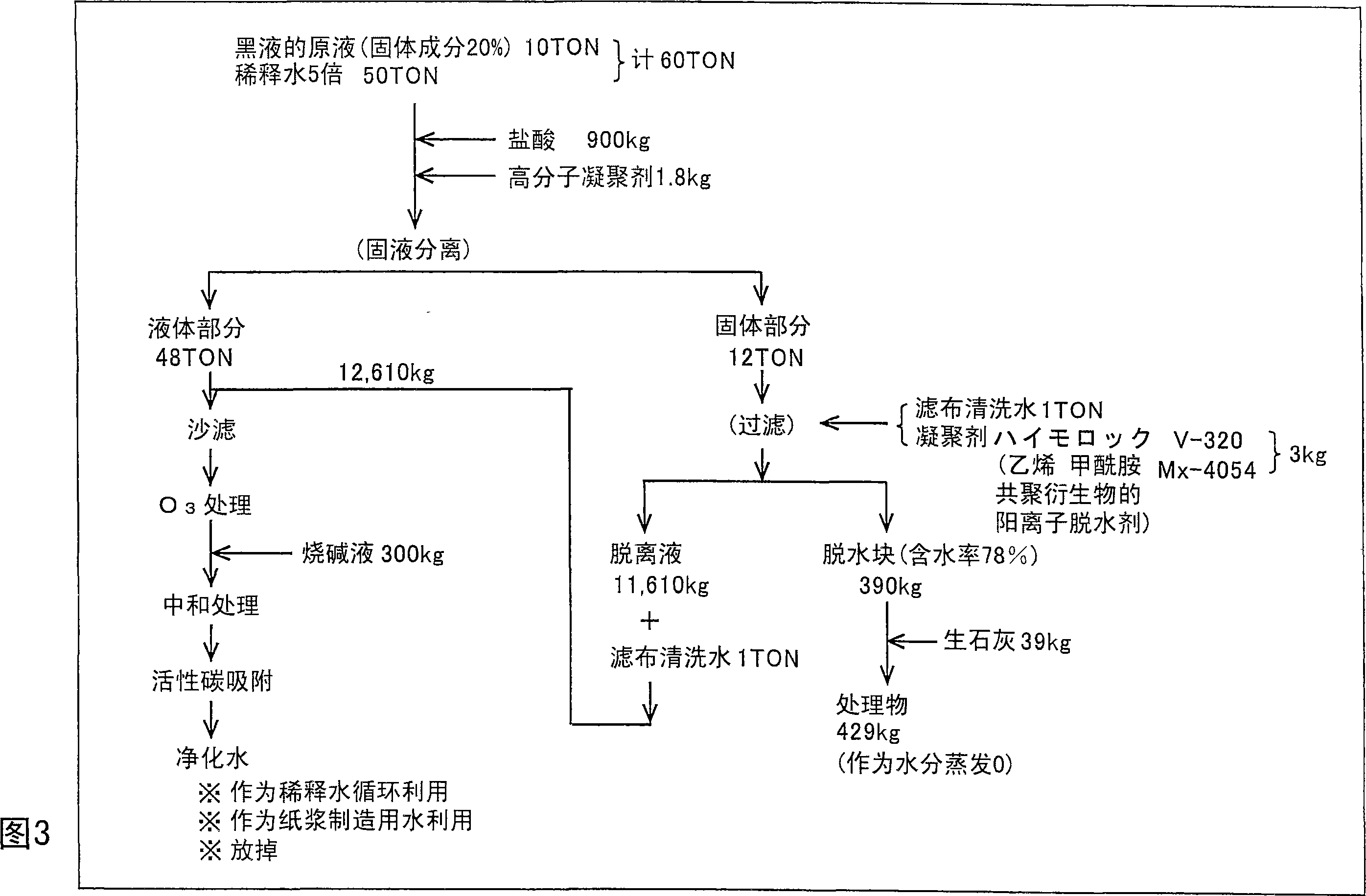

[0042] The processing of black liquor is carried out according to the flowchart shown in FIG. 3 .

[0043] First, add 50t of dilution water to the stock solution of 10t black liquor (containing 20% solid content) to obtain a total of 60t of treated liquid, add 900kg of hydrochloric acid therein, add 1.8kg of polymer coagulant while stirring, then place, Separation into a liquid part and a solid part.

[0044]The obtained liquid part 48t is subjected to sand filtration, microbubble ozone gas is introduced into the filtered water obtained through sand filtration for oxidation treatment, and then 300 kg of caustic soda is added for neutralization treatment. Next, the neutralized water was passed into an activated carbon tower to perform adsorption treatment of impurities to obtain purified water.

[0045] This purified water is used as the above-mentioned dilution water or pulp manufacturing water.

[0046] On the other hand, 12 t of solids obtained from the above solid-liqui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com