Laser machining system

A technology of laser processing and laser processing machines, which is applied in laser welding equipment, general control systems, metal processing equipment, etc., can solve problems that are difficult to realize, and achieve the effects of good controllability, easy automatic control, and automatic control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

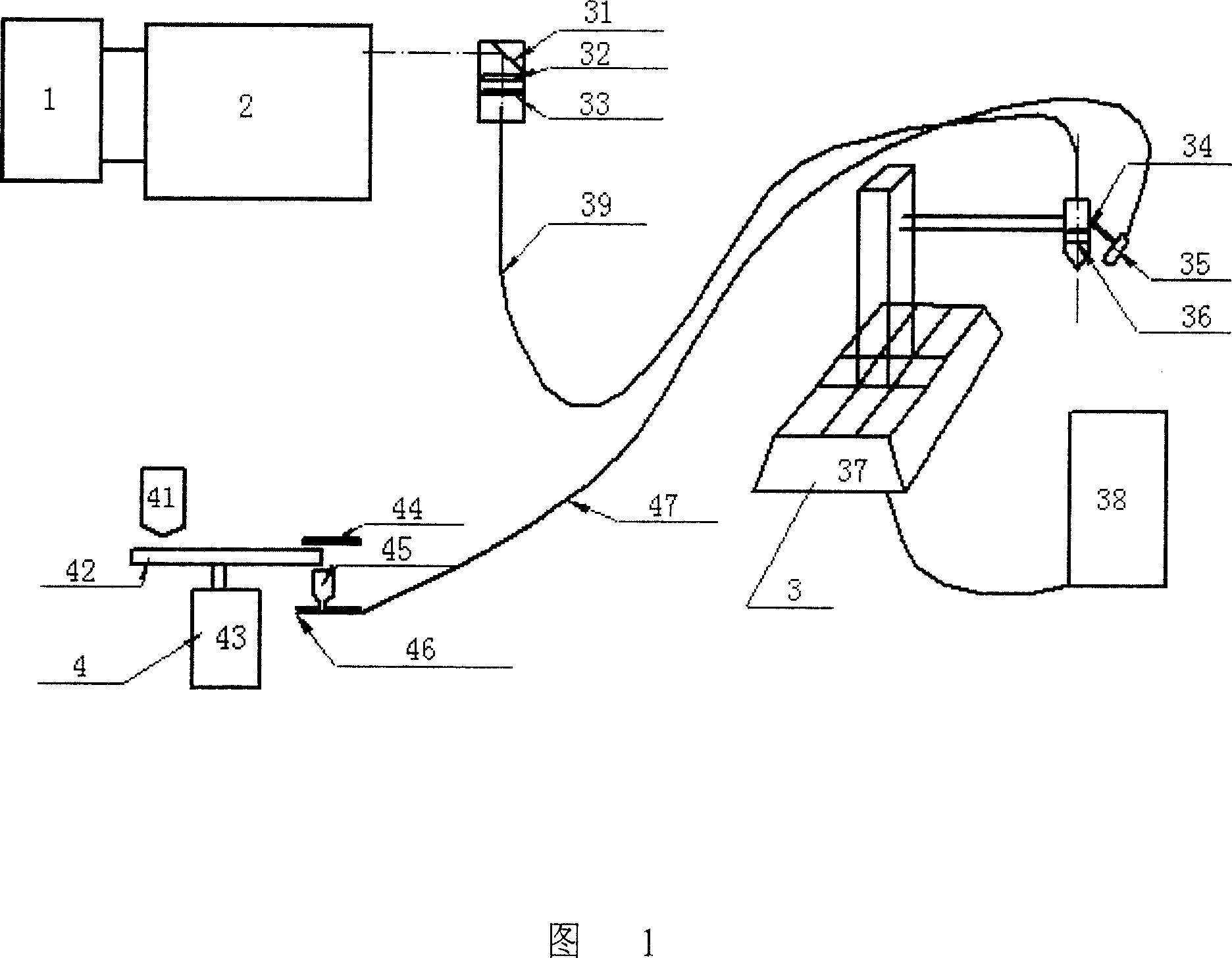

Image

Examples

Embodiment 1

[0017] The laser processing system consists of a laser 2, a laser processing machine 3, a water chiller 1 and a synchronous powder feeder 4. The laser 2 is a solid-state laser, and the laser processing machine 3 consists of laser and optical fiber coupling components, optical fiber components 39, focusing components, and movement axes. Component 37 and its control system 38; the laser and fiber coupling component consists of a focusing mirror 31, a beam expander 32, a reflector 33 and its bracket, and is connected to the laser 2; the fiber optic component 39 is connected to the laser and fiber coupling component and focusing component; Focusing part is made up of focusing lens 34, protective eyeglass 36 and lens barrel thereof, and cold water is passed inside lens barrel to cool eyeglass, is placed on the motion shaft part 37; Motion shaft part 37 is controlled by control system 38. The powder feeder 4 is composed of a hopper 41, a disc 42, a control motor 43, a scraper 44, a h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com