Method for preparing aqueous nontoxic degradable polyurethane elastomer

A polyurethane elastomer, water-based technology, applied in the field of preparation of water-based non-toxic and degradable polyurethane elastomer, can solve the problems of restricting the normal use of medical devices, increasing the production cost of products, yellowing of emulsions and products, and achieving good strength and saving. Energy, the effect of increasing stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1、2

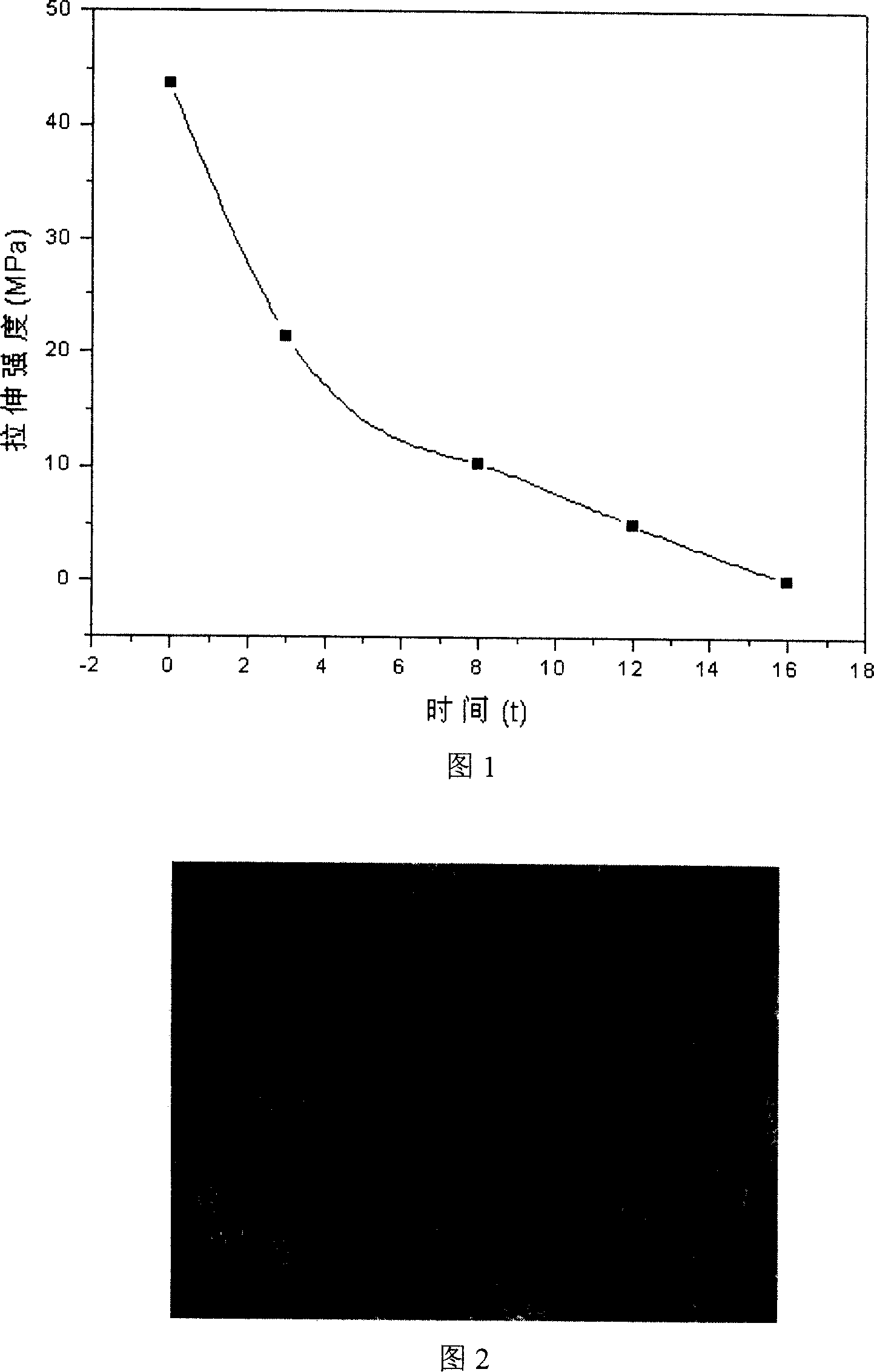

[0047] These two are examples in which no chain extension reaction is performed.

[0048] Firstly, polyester polyol and polyether polyol are added to a reaction kettle equipped with a stirrer, a thermometer and nitrogen protection, heated to raise the temperature, and vacuum dehydrated, then lowered the temperature, and then added diisocyanate and catalyst for prepolymerization reaction; after the reaction , under strong stirring, add water to emulsify, and the emulsification ends to obtain a light blue transparent polyurethane aqueous emulsion. The emulsion can be used to prepare products with lower strength requirements, such as drug carriers and the like. The raw material formula of each embodiment is shown in Table 1, and the process control conditions are shown in Table 2.

Embodiment 3~7

[0050] Firstly, polyester polyol and polyether polyol are added to a reaction kettle equipped with a stirrer, a thermometer and nitrogen protection, heated to raise the temperature, and vacuum dehydrated, then lowered, and then added diisocyanate and catalyst for prepolymerization reaction; lowered the temperature again, And add low-molecular-weight chain extender I to carry out chain extension reaction; under strong stirring, add water to emulsify, add low-molecular-weight chain extender II at the same time to extend the chain again, and dropwise add neutralizer to neutralize the carboxyl groups generated, and the emulsification is completed to obtain Slight blue transparent polyurethane aqueous emulsion. The emulsion can be used to prepare products with high mechanical performance requirements, such as artificial heart valves, artificial cardiac pacemaker insulated wires, artificial blood vessels, artificial blood vessel stents and the like. The raw material formula of each ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com