Purified cochineal and method for its production

a cochineal and purification technology, applied in the field of cochineal purification, can solve the problems of limited color concentration, sedimentation of conventional cochineal colors, and type and application of products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

[0072] (1) Preparation of Cochineal Color and a Colorant Product

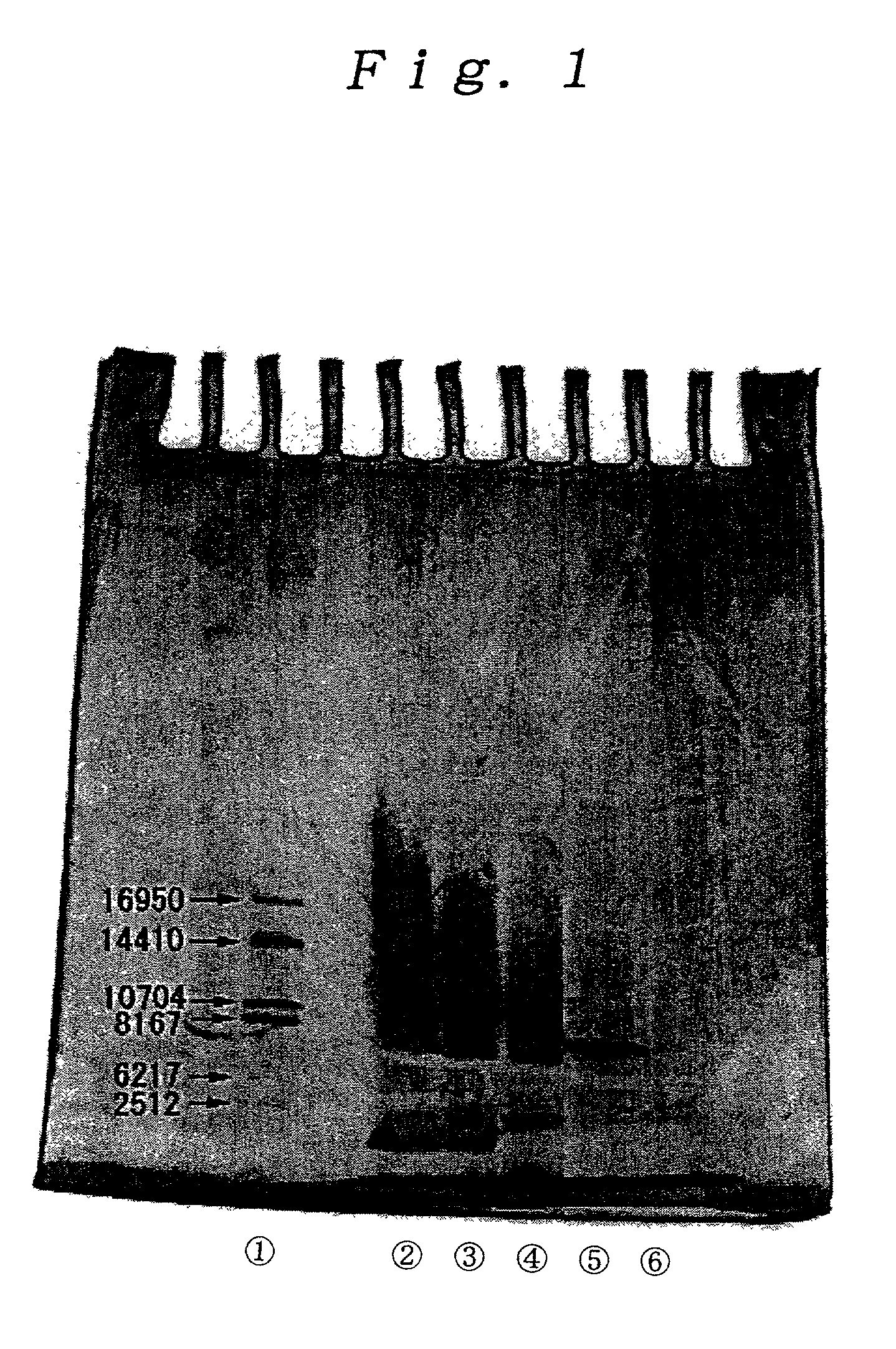

[0073] To 35 kg of the dry powder of the insect Coccus cacti L. was added 800 L of water adjusted to pH 7.5 with sodium hydroxide and the cochineal color was extracted at 90.about.100.degree. C. with stirring for 20.about.30minutes. The extract solution was passed through a 60-mesh metal sieve for solid-liquid separation and the liquid phase (cochineal extract solution) was adjusted to pH 4 with citric acid and cooled to about 50.degree. C. At this stage, 0.1% of protease was added and the mixture was stirred at that temperature for 3 hours. Then, the protein hydrolysate obtained was adjusted to pH 3 with citric acid, mixed with the filter aid and diatomaceous earth, and filtered through filter paper to recover about 250 L of the protein hydrolysate. This cochineal protein hydrolysate was run onto a column packed with the adsorbent resin Amberlite XAD-7 (150 L) to adsorb cochineal color. After the resin column was washe...

example 2

[0083] To 24 kg of the cochineal colorant product with a color value of E.sup.10%.sub.1 cm=60 as prepared in Example 1 was added 156 kg of water, and 8 kg of tartaric acid, 9.3 kg of burnt alum and 0.6 kg of slaked lime (calcium hydroxide) were dissolved in the resulting color liquor (pigment solution). Then, under stirring, the temperature was raised to 80.degree. C. and held at this level for 5 hours, whereby a water-insoluble cochineal aluminum lake (carmine) was obtained. This aqueous suspension of carmine was filtered with a filter press (Yabuta Co.) to recover a carmine cake, which was then dried in vacuo at 50.degree. C. and crushed to prepare a carmine powder.

[0084] Protein analysis of this carmine by the same method of electrophoresis as in Example 1 showed no evidence of protein. It was, therefore, clear that a carmine substantially free of proteins as potential allergens can be prepared by the method described in Example 1.

[0085] In this connection, according to the findi...

example 3

[0086] The cochineal colorant product with a color value of E.sup.10%.sub.1 cm=60 prepared in Example 1 was examined for the presence of an odor. More specifically, 5 g of the cochineal color product was diluted with water to thereby prepare 1 L of a solution with a color value of E.sup.10%.sub.1 cm=0.3. The resulting solution was heated to the temperature of 50.degree. C. and then evaluated for its odor based on the judgments made by a panel of 10 highly-trained specialists. As a comparative sample for the evaluation were used a cochineal extract (pH 7.5) obtained from the dry powder of the insect Coccus cacti L. by a water extraction following the procedures of Example 1 (comparative color 1) and a cochineal color prepared by further subjecting the cochineal extract obtained by the water extraction to resin adsorption treatment (comparative color 2). The comparative samples were used for the evaluation of odors after diluted in the same manner as described above to prepare a solut...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Color | aaaaa | aaaaa |

| Molecular weight | aaaaa | aaaaa |

| Adsorption entropy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com