High yiel vapor phase deposition method for large scale sing walled carbon nanotube preparation

a carbon nanotube and vapor phase deposition technology, applied in the field of high yiel vapor phase deposition method for large-scale sing-walled carbon nanotube preparation, can solve the problem of not being able to increase the production volume of nanotube materials from laboratory to industrial scale, and unable to produce a sufficient amount of materials, etc. problems, to achieve the effect of high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example ii

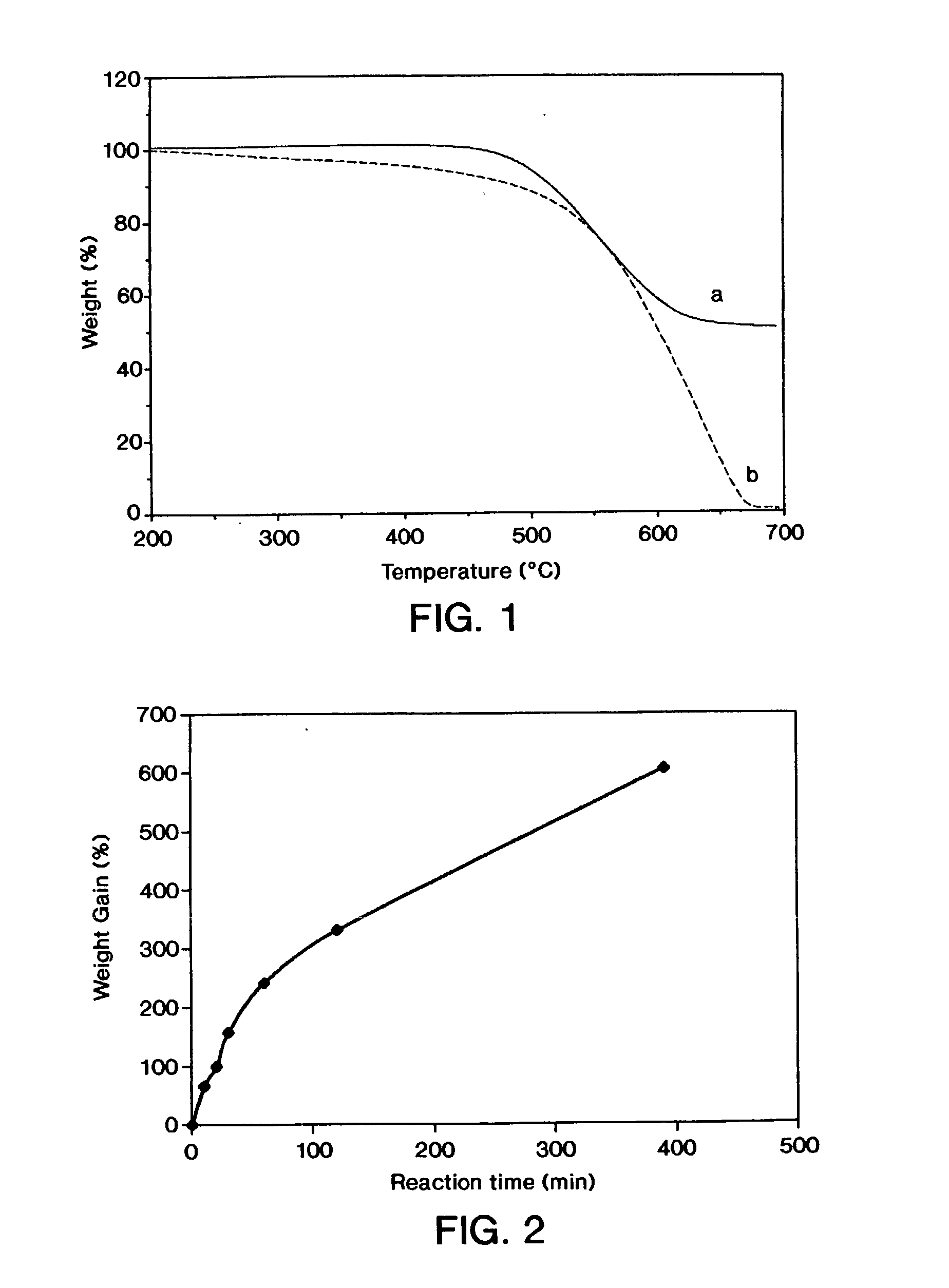

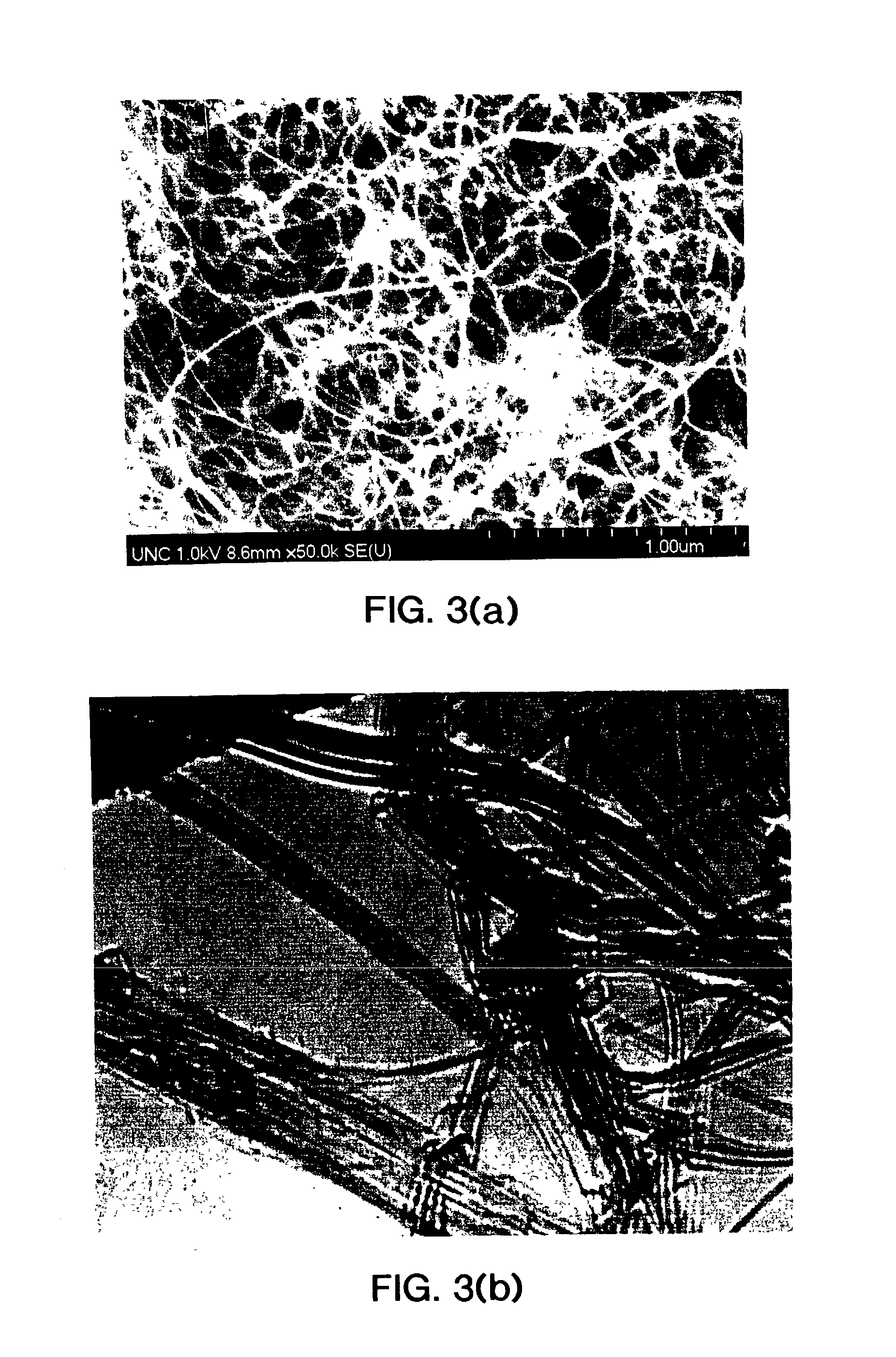

[0061] The procedure of Example I was substantially repeated, except this time with a methane flow for about 60 minutes (instead of about 30 minutes) and a temperature of about 900.degree. C. (instead of various temperatures of about 800.degree. C. about 850.degree. C., about 900.degree. C., and about 950.degree. C.) and a flow rate of about 1158 sccm (instead of about 1000 sccm), during SWCNT growth. The yield measured by TGA was about 200%.

example iii

Comparison

[0062] Also, a catalyst / support made from the same Al.sub.2O.sub.3 wet gel, but dried differently to make xerogel, was compared. The aerogel supported catalyst showed a yield of about 200% of high purity SWCNT under a methane flow at about 900.degree. C. for about 60 minutes, as reported by Example I. On the other hand, the xerogel supported catalyst showed a weight gain of <5% under the same conditions.

example iv

[0063] The procedure was repeated as per the Fe / Mo catalyst supported on Al.sub.2O.sub.3 aerogel, but this time with the Fe / Mo catalyst instead supported on SiO.sub.2 aerogel prepared by a similar method.

[0064] The weight gain of the catalyst on SiO.sub.2 aerogel under the same conditions, about 900.degree. C. under a methane flow for about 60 minutes, was almost 10%. Thus, it appears that although a SiO2 aerogel support works (i.e., about 10%), it is preferred with the inventive method to employ an Al.sub.2O.sub.3 aerogel support or an Al.sub.2O.sub.3 / SiO.sub.2 aerogel support to obtain improvements that are far superior (i.e., weight gain of about 100% or greater).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com