Process for preparing dry extracts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

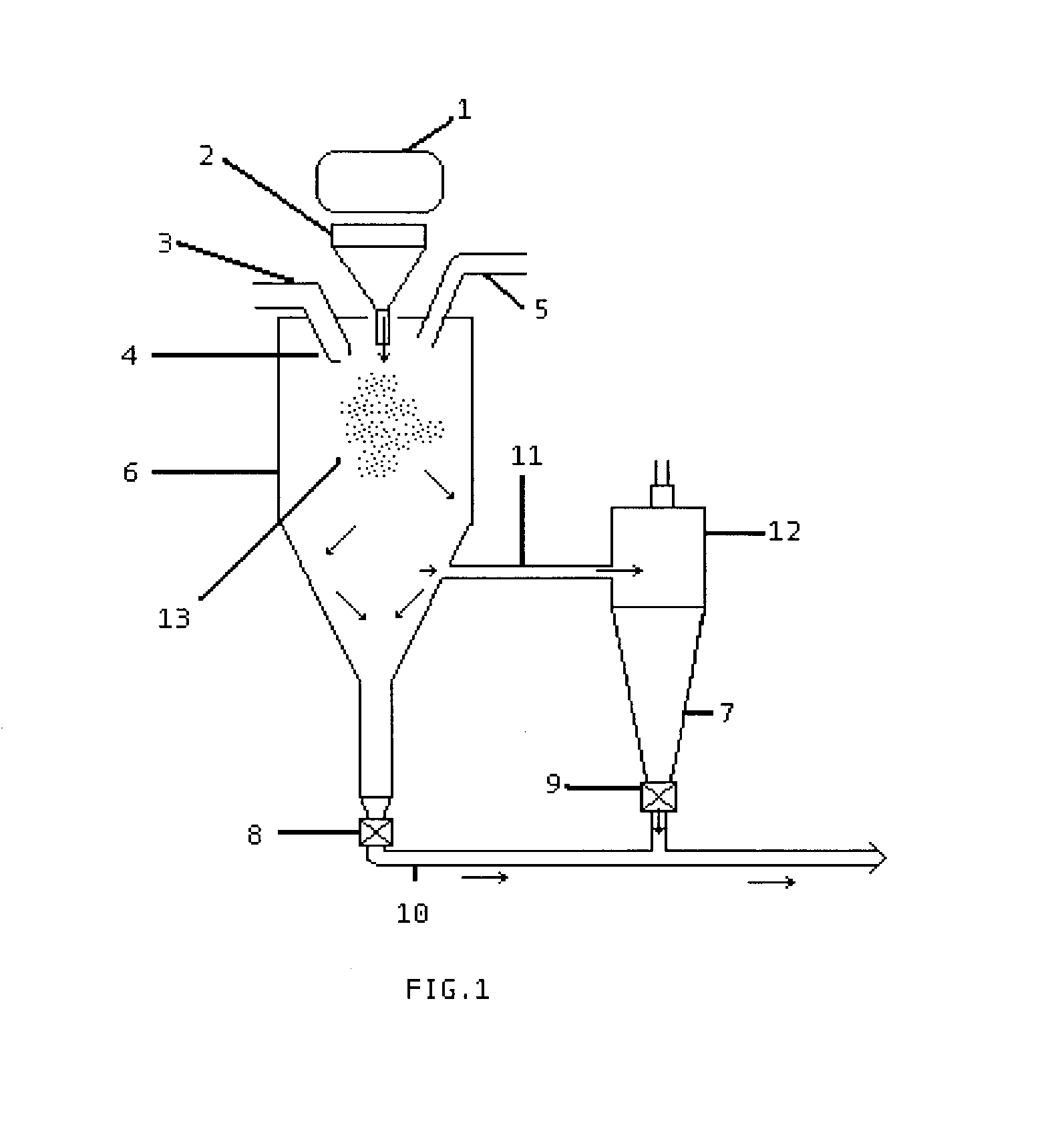

Method used

Image

Examples

example 1

[0052] 146.5 kg of St. John's wort (SJW) extract having a dry content of 47.8% was spray-dried together with 30.00 kg of silicified / silicated microcrystalline cellulose at an air entry temperature of 210.degree. C. and under a nozzle pressure of 40 bar to obtain 93.6 kg of dry product.

example 2

[0055] 132.2 kgs of Panax ginseng (PG) extract having a dry content of 43.8% was spray-dried together with 25.0 kgs of silicified / silicated microcrystalline cellulose at an air entry temperature of 205.degree. C. and under a nozzle pressure of 40 bar to obtain 83.6 kg of dry product.

examples 3a-h

[0058] According to Example 1, similar products of the following botanical extracts and nutraceuticals or dietary supplements (DS) were manufactured. 15 to 245 kg fluid feed of below shown botanical extracts or dietary supplement solutions having a dry content of 32 to 53% were spray-dried together with 25 to 40% of dry silicified / silicated microcrystalline cellulose at an air entry temperature of 175-250.degree. C. and under a nozzle pressure of about 40 bar to obtain dry product with yields of 85 to 95%.

3 Botanical Extract / DS Characteristic Remarks Artichoke (Cynara scolymus) Free-flowing, fair hygroscopic Pure extract is extreme hygroscopic Echinacea (E. spp.) Low moisture uptake Eleuthococcus (E. senticosus) Free-flowing powder Pure extract tends to lump Gingko biloba Good to handle; fine powder Green tea (Camellia sinensis) Good compressible powder Garlic (Allium sativum) Powder with good flowability Raw material is sticky and hygroscopic. Horse chestnut (Aesculus Good compacta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com