Molten metal supply device and aluminum titanate ceramic member having improved non-wettability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

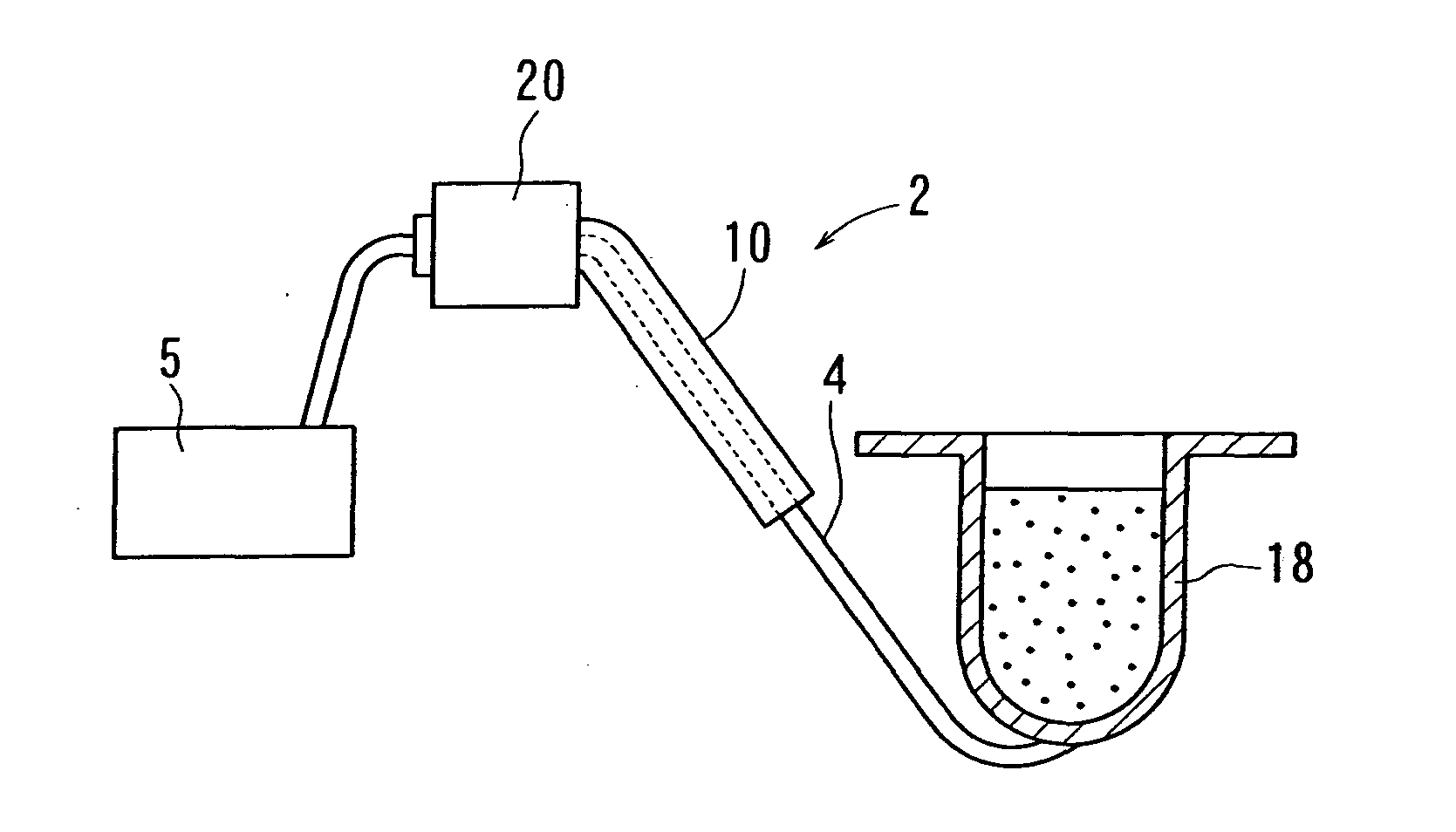

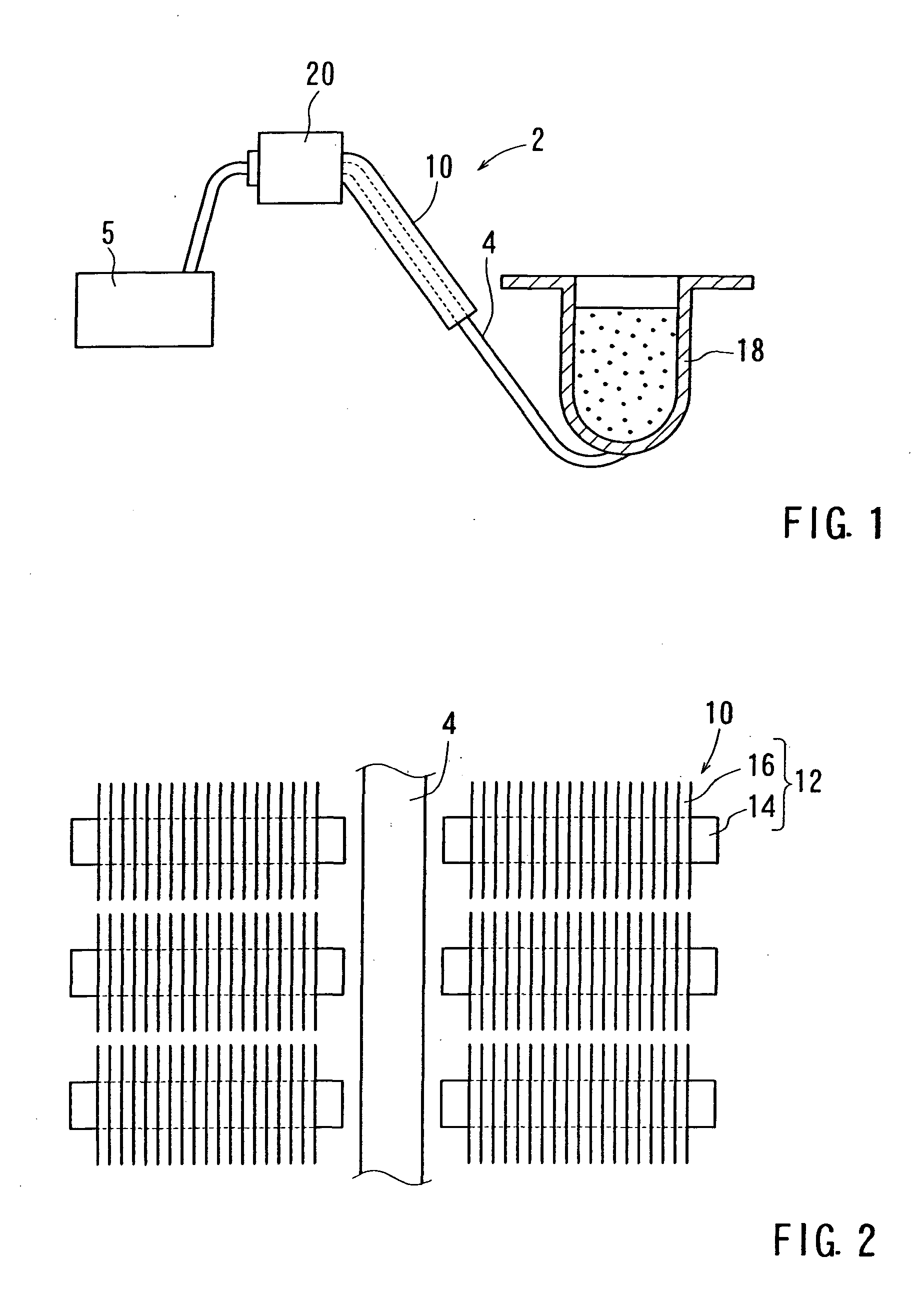

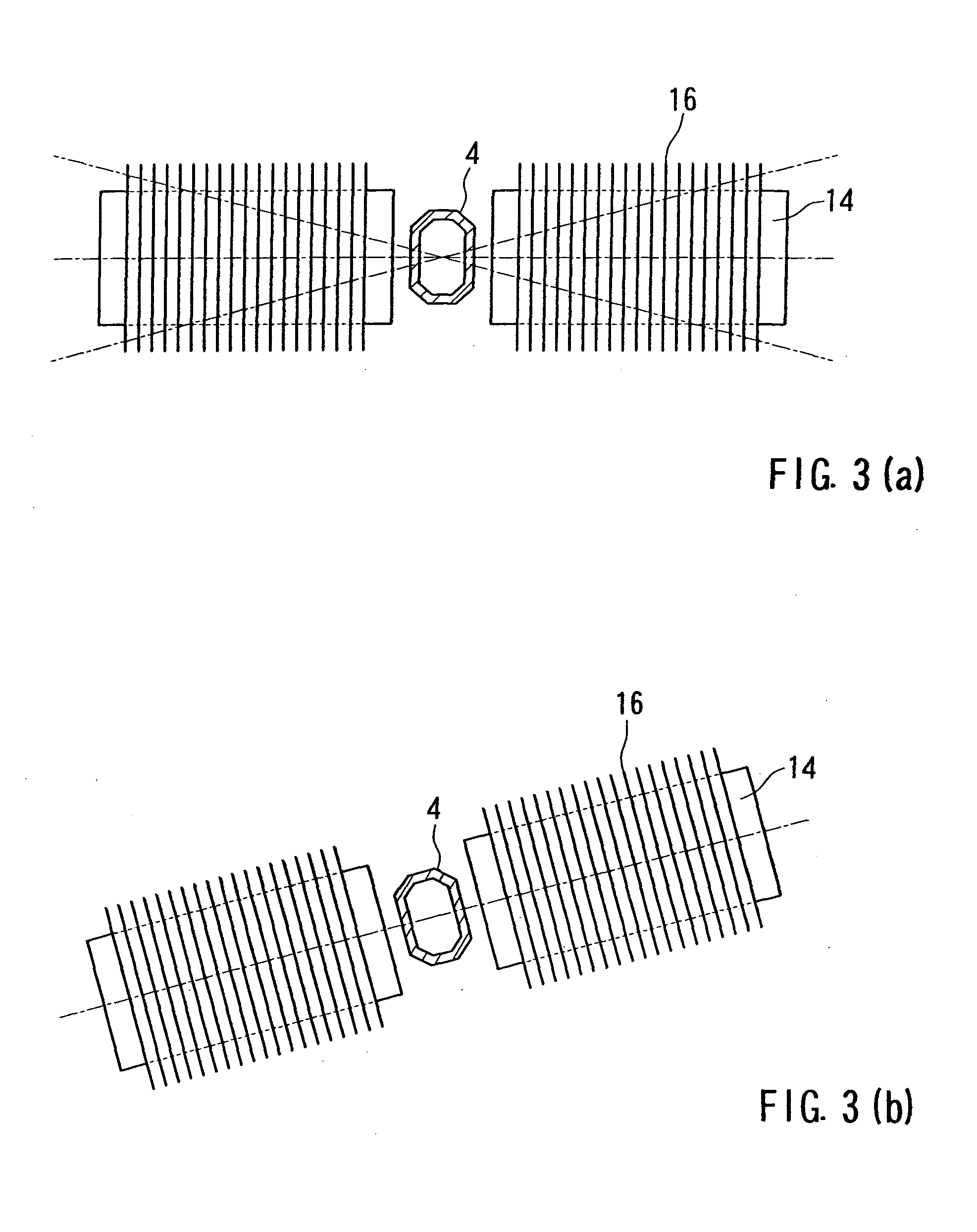

Image

Examples

embodiment 1

f the Aluminum Titanate Ceramic

The aluminum titanate (Al2TiO5) base powder that was used was Marusu Yuuyaku's TA-2 (containing 5 wt % SiO2) . Water and an alumina ball were added to the base powder, the weight ratio of raw material : alumina ball : water was adjusted to 1:1:0.7, and this mixture was mixed in a ball mill for 63 hours. After that, the Al2TiO5 slurry was passed through a sieve (200 mesh), and water was extracted therefrom with a filter press to obtain an Al2TiO5 press cake.

To this press cake were added suitable amounts of water, a deflocculating agent (manufactured by Chukyo Yushi, product name: D-305), a binder (manufactured by Chukyo Yushi, product name: WE-518), and the slurry density was adjusted to 2.1 to 2.3 g / cm3.

After this, this slurry was poured into a plaster mold, and after it was cast, it was dried at room temperature to obtain a green compact. Two types of green compact were produced, the ladle shape shown in FIG. 13 and the vessel shaped bonded set (...

embodiment 3

f Non-wettability

(1) Wetting Angle

The wetting angle is measured in order to evaluate the non-wettability of the Al2TiO5 ceramic sintered compact with respect to the molten aluminum alloy (A4C).

The following three types of Al2TiO5 ceramic test pieces were used. In other words, i) a test piece in which the surface of the sintered compact produced in Embodiment 1 was cut into a 25 mm×25 mm×6 mm piece, surface-finished to 25 mm×25 mm (thickness of 5 mm) by means of a #800 diamond grindstone, and had a surface roughness (center line average roughness) of approximately 3 μm; ii) a test piece with the same surface finish, on whose surface an α-Al2O3 layer having a thickness of 5 μm was formed according to Embodiment 2; and iii) a test piece obtained by immersing an Al2TiO5 ceramic sintered body on which an α-Al2O3 layer had been formed in a molten aluminum alloy (A4C, 720 degrees C.) for 50 hours in order to change the surface of the α-Al2O3 layer to an MgAl2O4 layer.

An MH-type guid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Force | aaaaa | aaaaa |

| Pressure | aaaaa | aaaaa |

| Volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com