Acidizing stimulation method using viscoelastic gelling agent

a gelling agent and viscoelastic technology, applied in fluid removal, chemistry apparatus and processes, borehole/well accessories, etc., can solve the problems of limiting the effectiveness of very near-wellbore applications, affecting the flow potential, damage to the formation, etc., to reduce iron hydroxide precipitation, improve acid penetration, and minimize damage risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The composition of the invention contains (i.) a HF-containing acidizing solution and (ii.) a solution of an amidoamine oxide gelling agent. In a preferred embodiment, the amidoamine oxide gelling agent solution is a glycol solution. Typically, the amount of HF-containing acidizing solution in the composition is between from about 92 to about 99.9 weight percent, preferably from about 94 to about 99.75 weight percent.

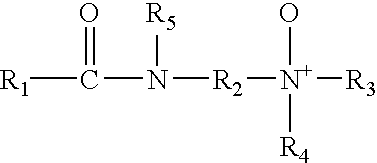

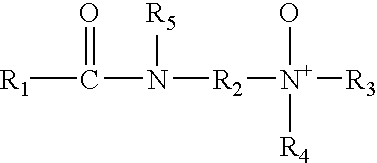

[0019] In a preferred mode, the amidoamine oxide is of the structural formula:

wherein R1 is a saturated or unsaturated, straight or branched chain aliphatic group of from about 7 to about 30 carbon atoms, preferably from about 14 to about 21 carbon atoms. More preferably, R1 is a fatty aliphatic derived from natural fats or oils having an iodine value of from about 1 to about 140, preferably from about 30 to about 90, and more preferably from 40 to about 70. R1 may be restricted to a single chain length or may be of mixed chain length such as those groups der...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com