PET with stress cracking resistance, preform and container made therewith and method

a technology pet, which is applied in the field of stress cracking resistance of articles, can solve the problems of environmental stress cracking, esc, and persistent annoyance, and achieve the effect of reducing intrinsic viscosity and molecular weigh

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

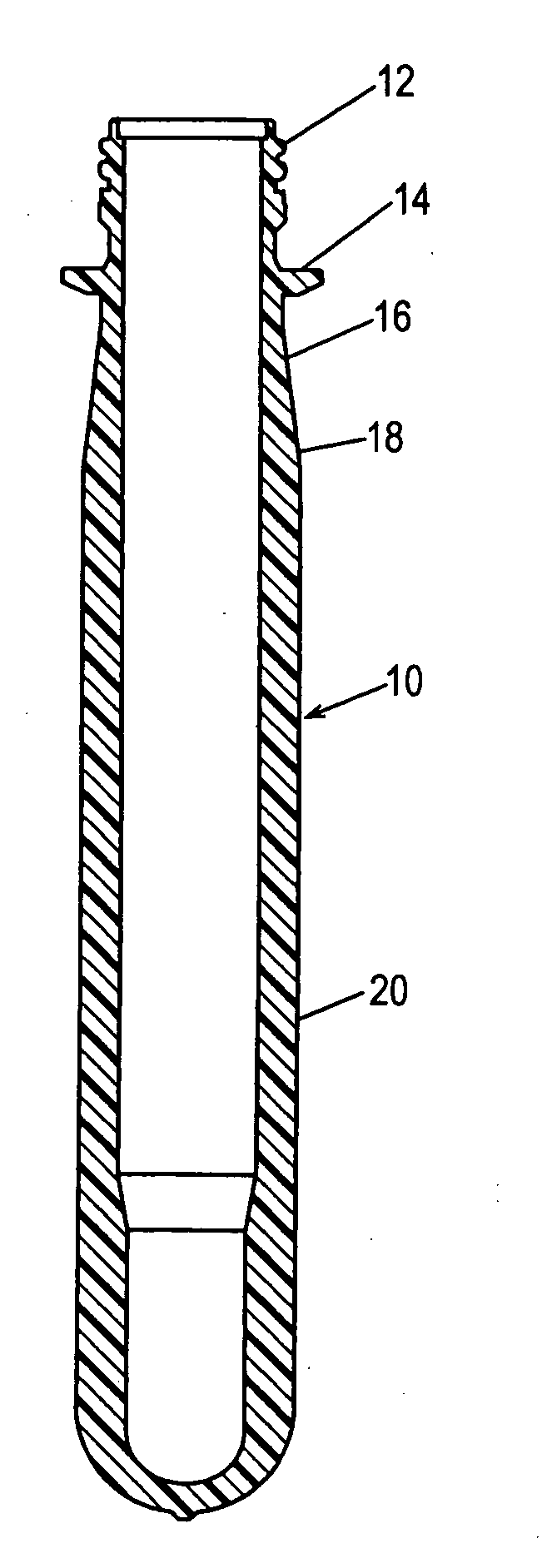

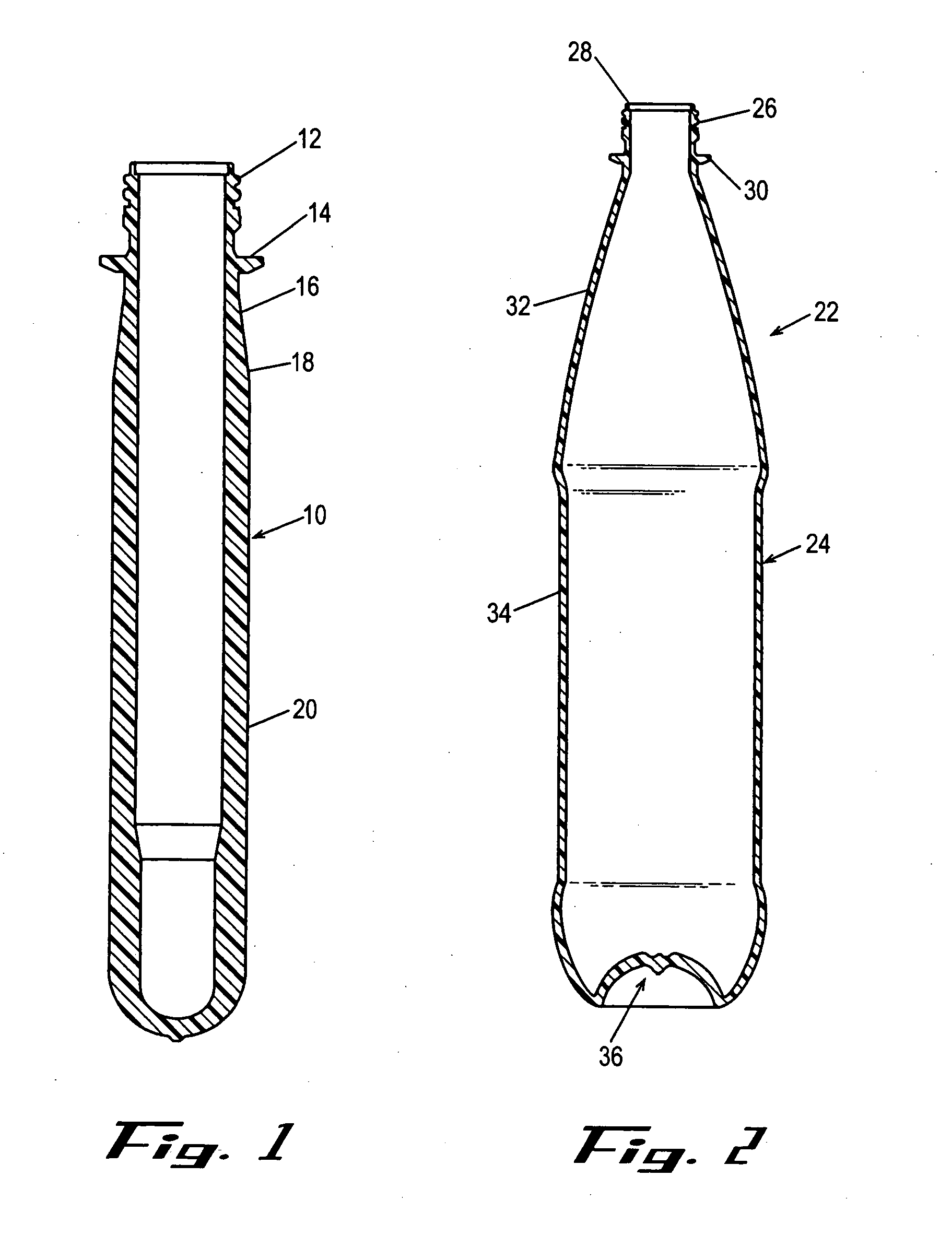

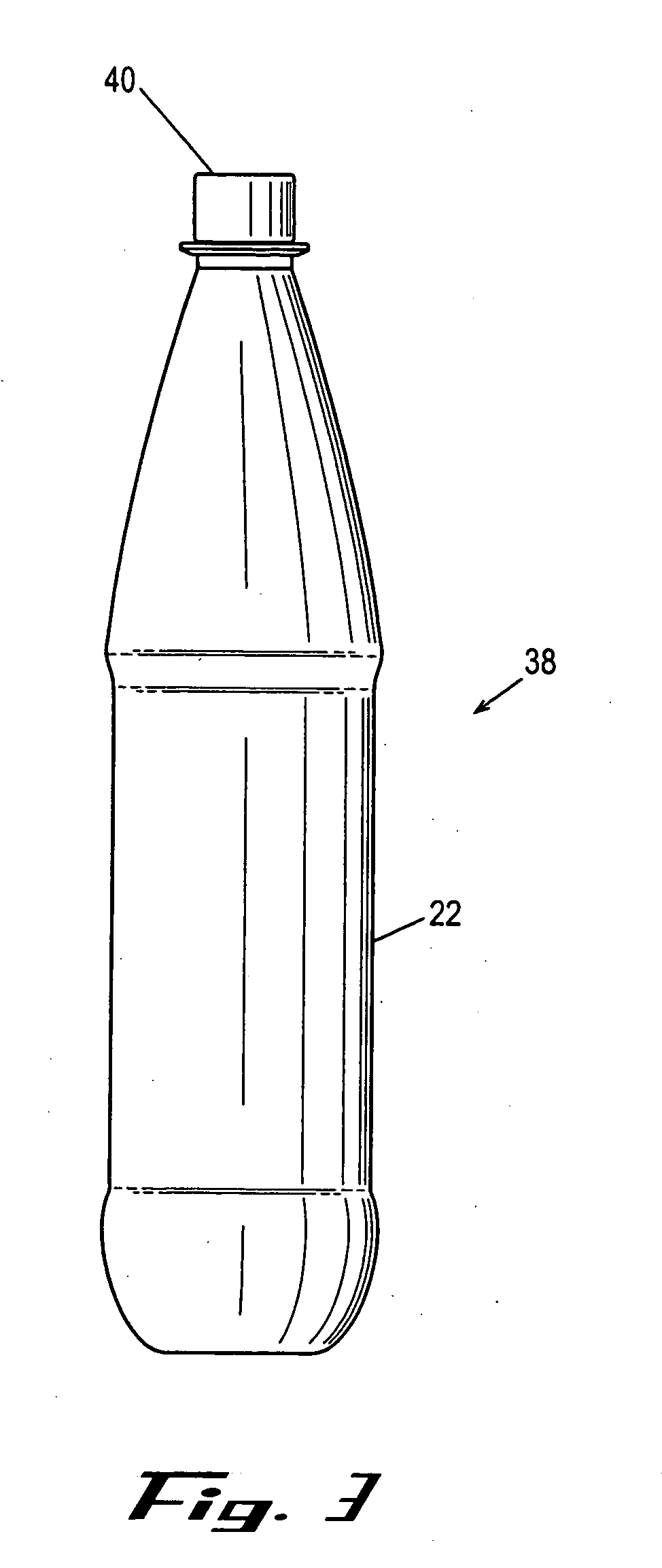

Image

Examples

example 1

[0036] Sample container preforms were injection molded using two different PET based resins and different stress crack resistance modifiers. Sample 1 was made with a first PET resin (R1), a commercially available CSD grade PET copolymer resin with an IV of 0.83, and Samples 2-6 were made with a second PET resin (R2), a commercially available water grade PET copolymer resin with an IV of 0.74. The compositions of the Sample preforms are set forth in Table 1.

[0037] Each preform was injection molded using 500 mL Contour design 28g preforms under conditions that were set to produce molded samples with no crystallinity, haze or other visual imperfections based on the control resin variable. The PET resins R1 and R2 were dried overnight at 280° F. to a moisture level below 50 ppm. The stress crack resistance additives, poly[ethylene-co-butyl acrylate] (PBA, Aldrich #43,077-3) and poly[ethylene-co-methyl acrylate] (PMA, Aldrich #43,266-0), were dried over the weekend in a vacuum oven with...

example 2

[0042] Sample container preforms were injection molded using two different PET based resins and different stress crack resistance modifiers. Sample 1 was made with a first PET resin (R3), a commercially available CSD grade PET copolyester resin with an IV of 0.84, and Samples 2-4 were made with a second PET resin (R4), a commercially available water grade PET copolyester resin with an IV of 0.74. The composition of the Sample preforms is set forth in Table 3.

[0043] The stress cracking resistance additive used was a commercially available Paraloid EXL core-shell impact modifier supplied by Rohm & Haas. The preforms were injection and blow molded according to Example 1. The containers were then subjected to the same tests and the results are shown in Table 4.

TABLE 3Resin / Additive VariablesActual %IVSampleResinAdditiveAdditive Added(dL / g)1R3Control-None00.7822R4Control-None00.6743R4EXL3.00.6514R4EXL6.00.638

[0044] The stress cracking test was performed the same as in the Example 2. A...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle sizes | aaaaa | aaaaa |

| weight percent | aaaaa | aaaaa |

| weight percent | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com