Devices Employing Colloidal-Sized Particles

a technology of colloidal particles and devices, applied in the direction of instruments, piston pumps, laboratory glassware, etc., can solve the problems of consuming significantly less space, requiring difficult etching procedures, and limiting the use of colloidal particles in such devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

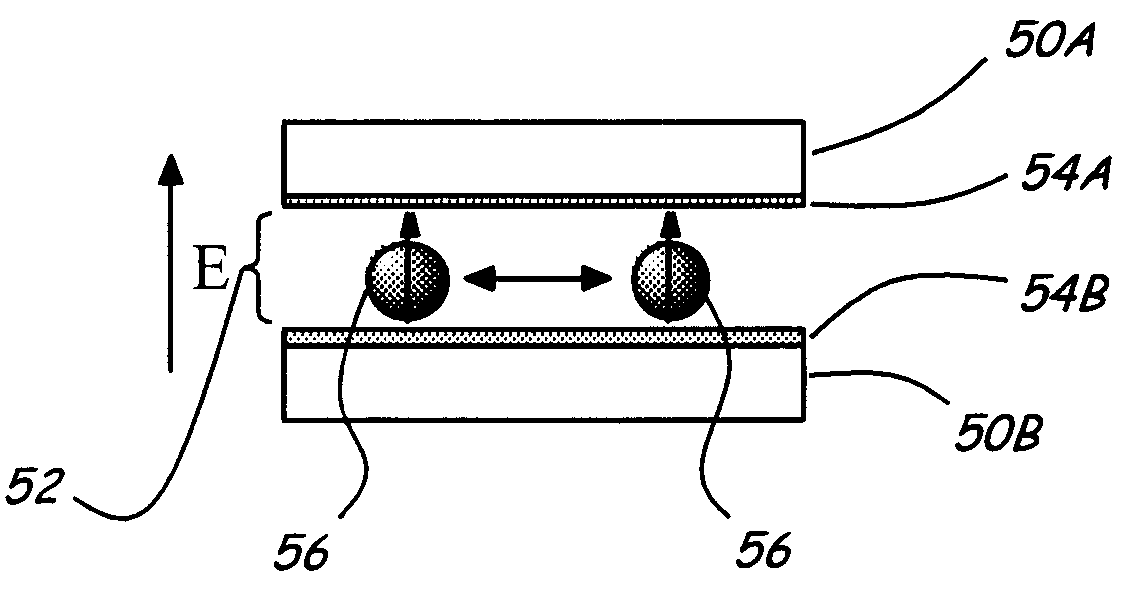

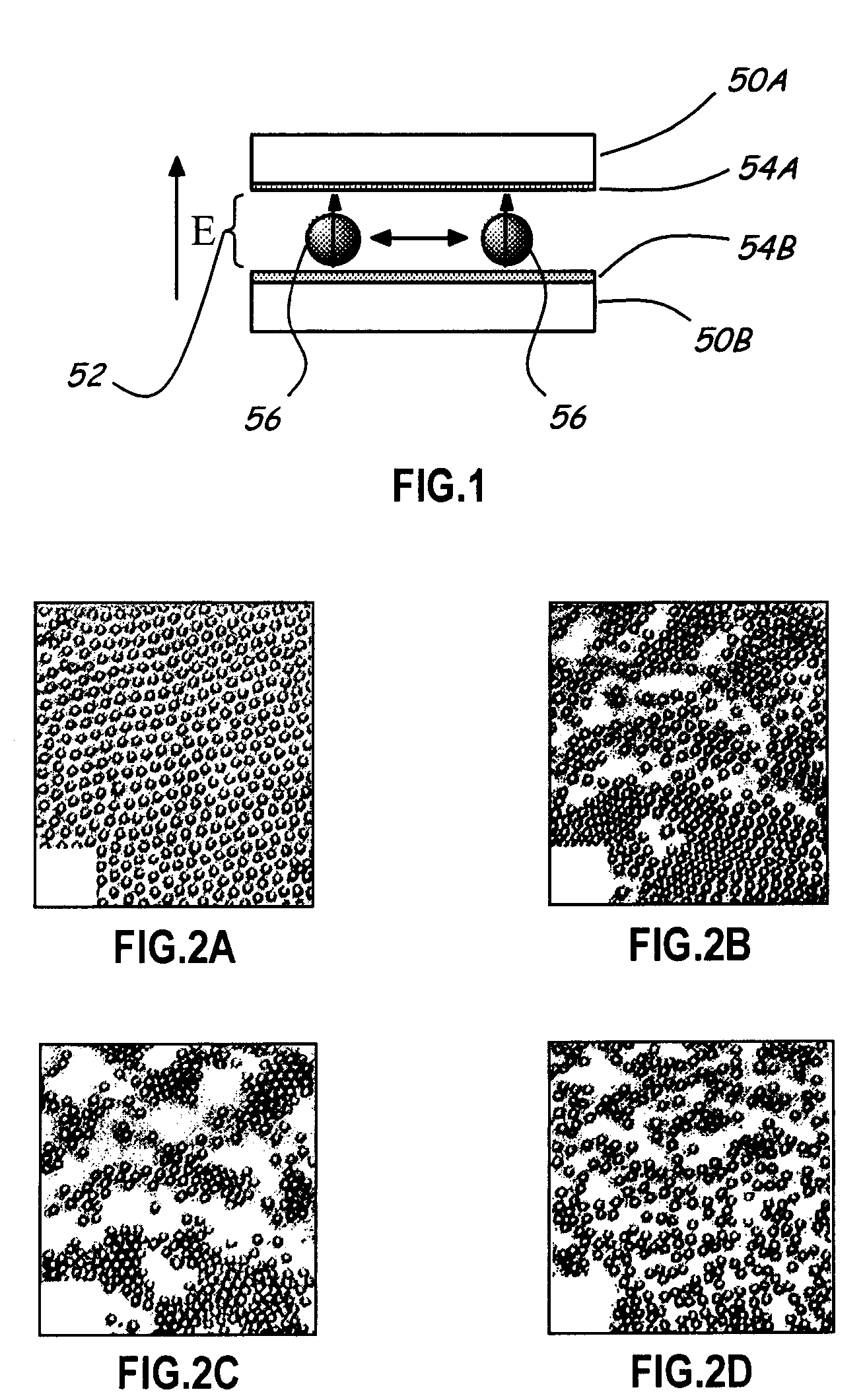

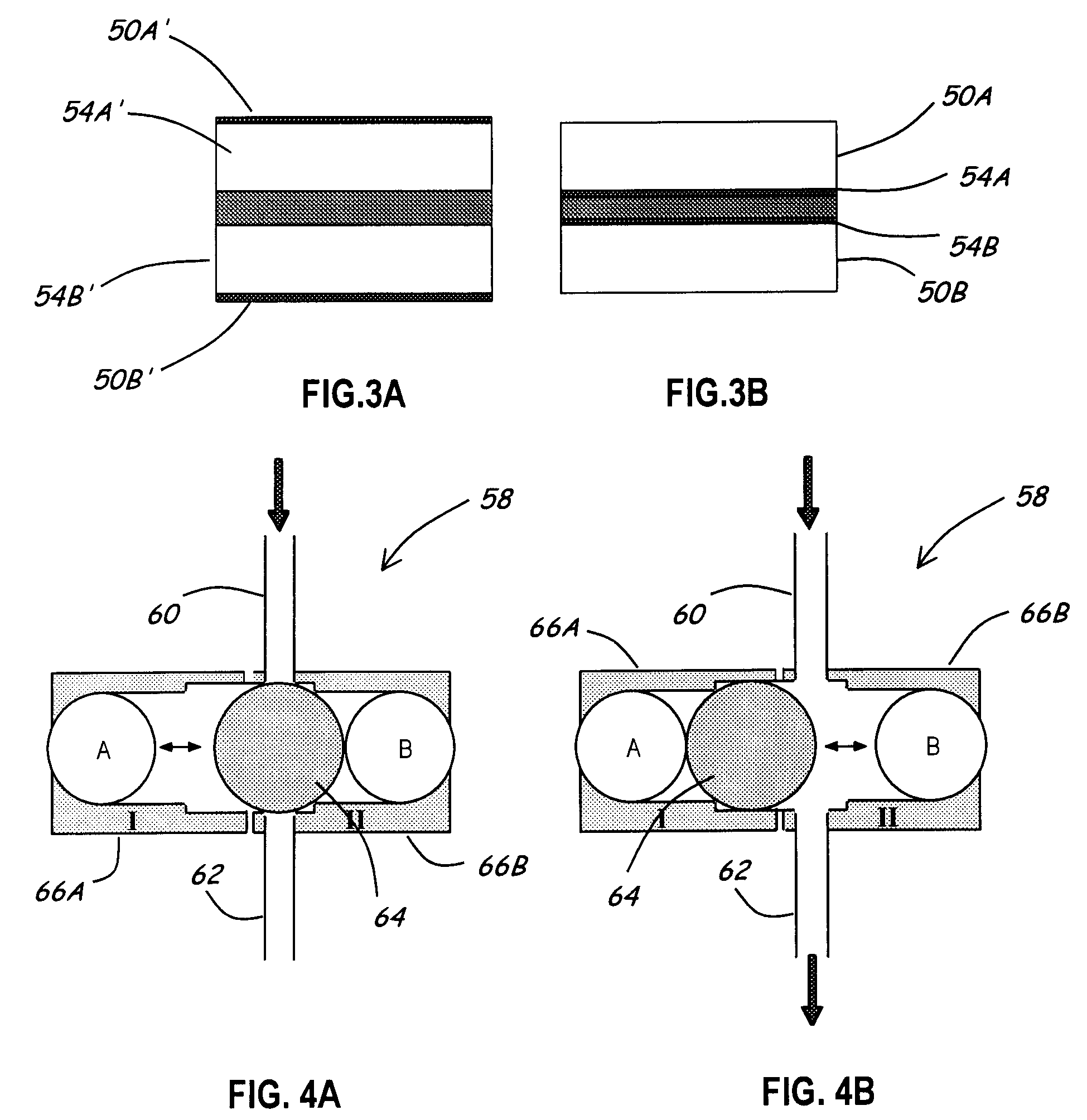

[0064] Described is the application of colloidal manipulation techniques using fields for the purpose of fluid control on the microscale. Colloidal particles, a generic term describing micron and submicron sized bits of solid matter suspended in a fluid medium, can respond to the application of external fields. Charged colloidal particles will migrate in an electric field due to the electrophoretic body force exerted by the field. Similarly, magnetizable particles can be translated or aligned with magnetic fields. Additionally, a monodisperse suspension of colloidal particles confined between two plates separated by roughly a single particle diameter will repulsively order in the presence of an electric field applied perpendicularly to the confining plane. Furthermore, colloidal particles can be trapped and manipulated individually with focused laser beams; a technique commonly referred to as “optical trapping” or “optical tweezing”. These four methods of colloidal particle manipula...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com