Electro-decontamination of contaminated surfaces

a technology of contaminated surfaces and electrolysis, which is applied in the direction of electrochemical machining apparatus, crystal growth process, nuclear engineering, etc., can solve the problems of surface abrasion, mechanical decontamination methods can have drawbacks, and can not only pose a significant health risk to decontamination personnel, but also spread to other areas, and achieves effective oxidized metal layers , the effect of fast removal of high levels of fixed and smearable contaminants

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

The Decontamination System

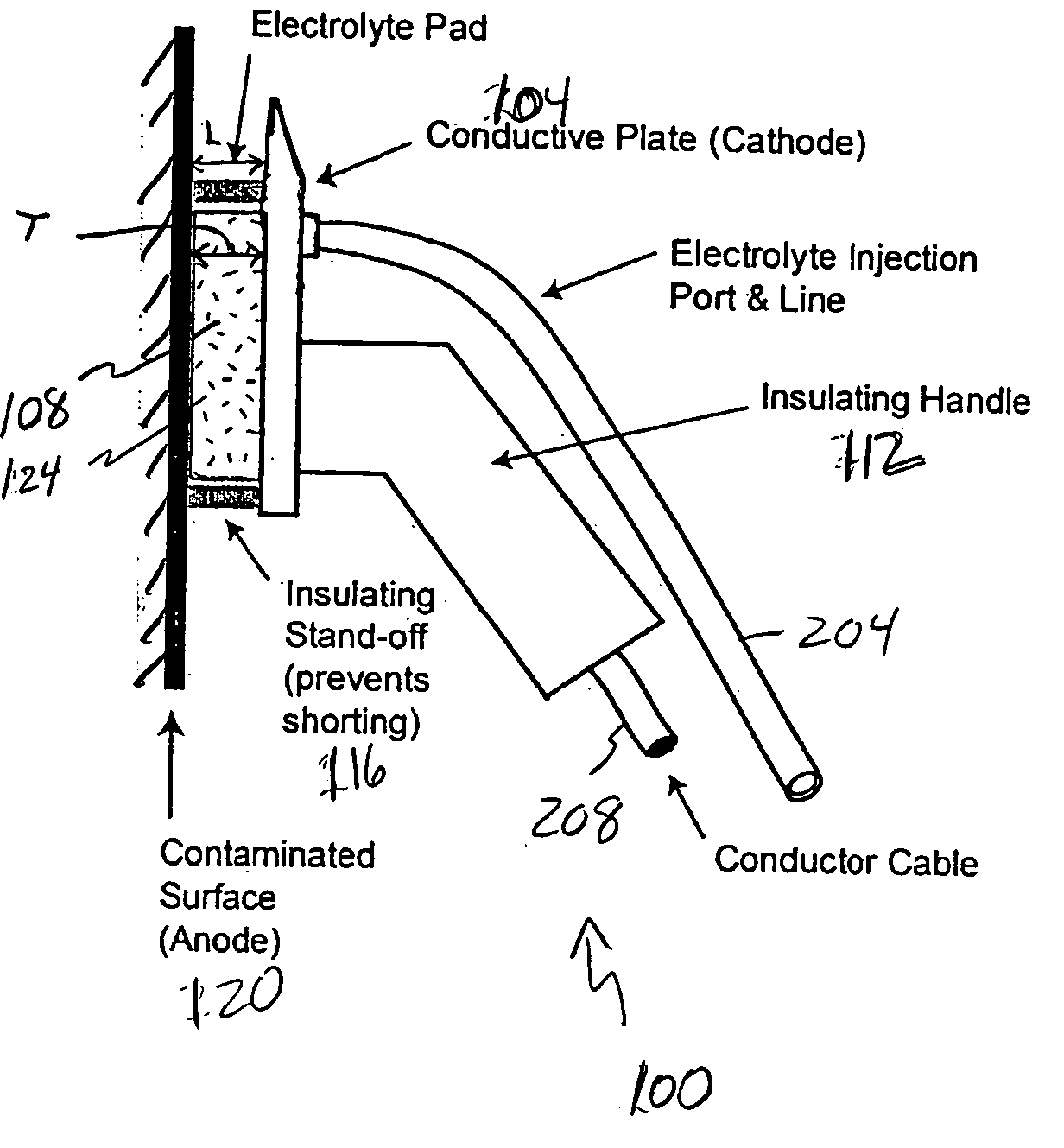

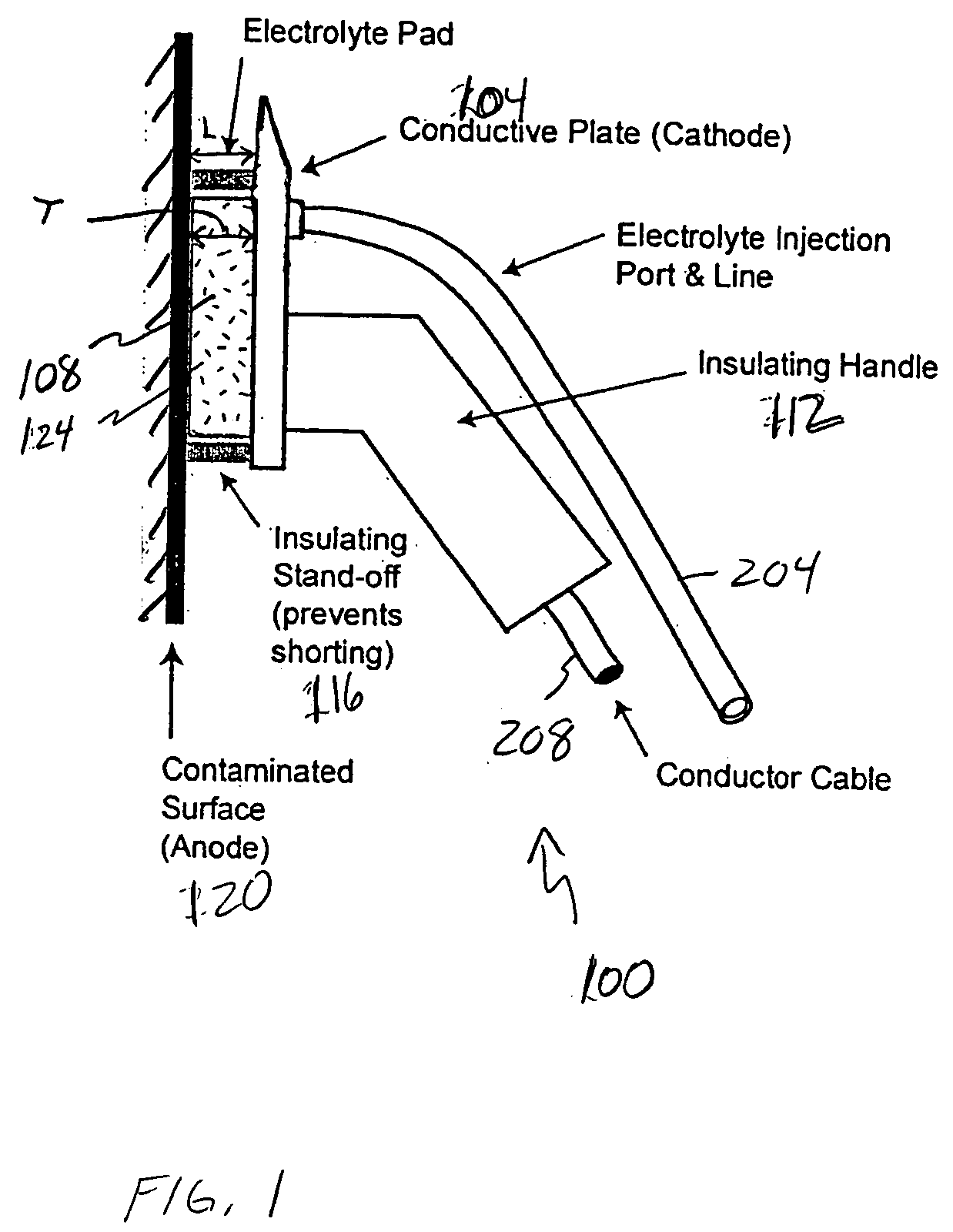

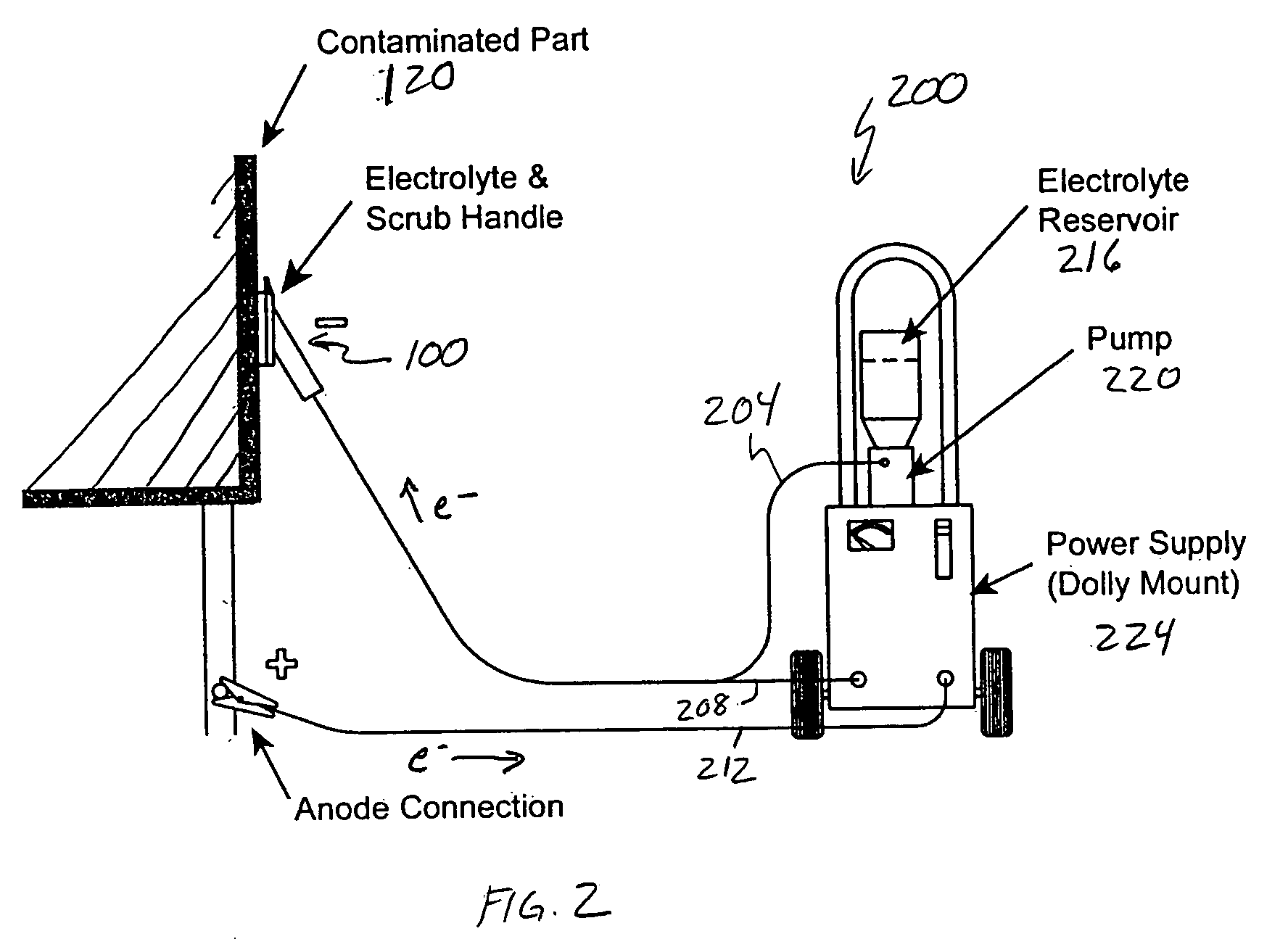

[0043] The decontamination system effectively combines the underlying concepts of electro-chemical decontamination or electropolishing, strippable decontamination coatings, and mechanical decontamination. The system uses a viscous and / or thixotropic electrolytic gel-like material that is applied to the decontaminated surface, subjected typically to an applied voltage waveform(though a single voltage can alternatively be applied) causing electrolytic stripping of the fixed and smearable contaminants, and cured to form a strippable coating containing the electrolytically removed contaminants. Although the gel-like material is discussed with reference to removal of radioactive contaminants, it is to be understood that the gel-like material may be used for any contaminant or undesired material that will itself or that is deposited on a surface containing one or more substances that will themselves be oxidized or reduced in the presence of an applied voltage / el...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| voltage | aaaaa | aaaaa |

| frequency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com