Positive electrode for use in lithium cell and lithium cell using the same

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

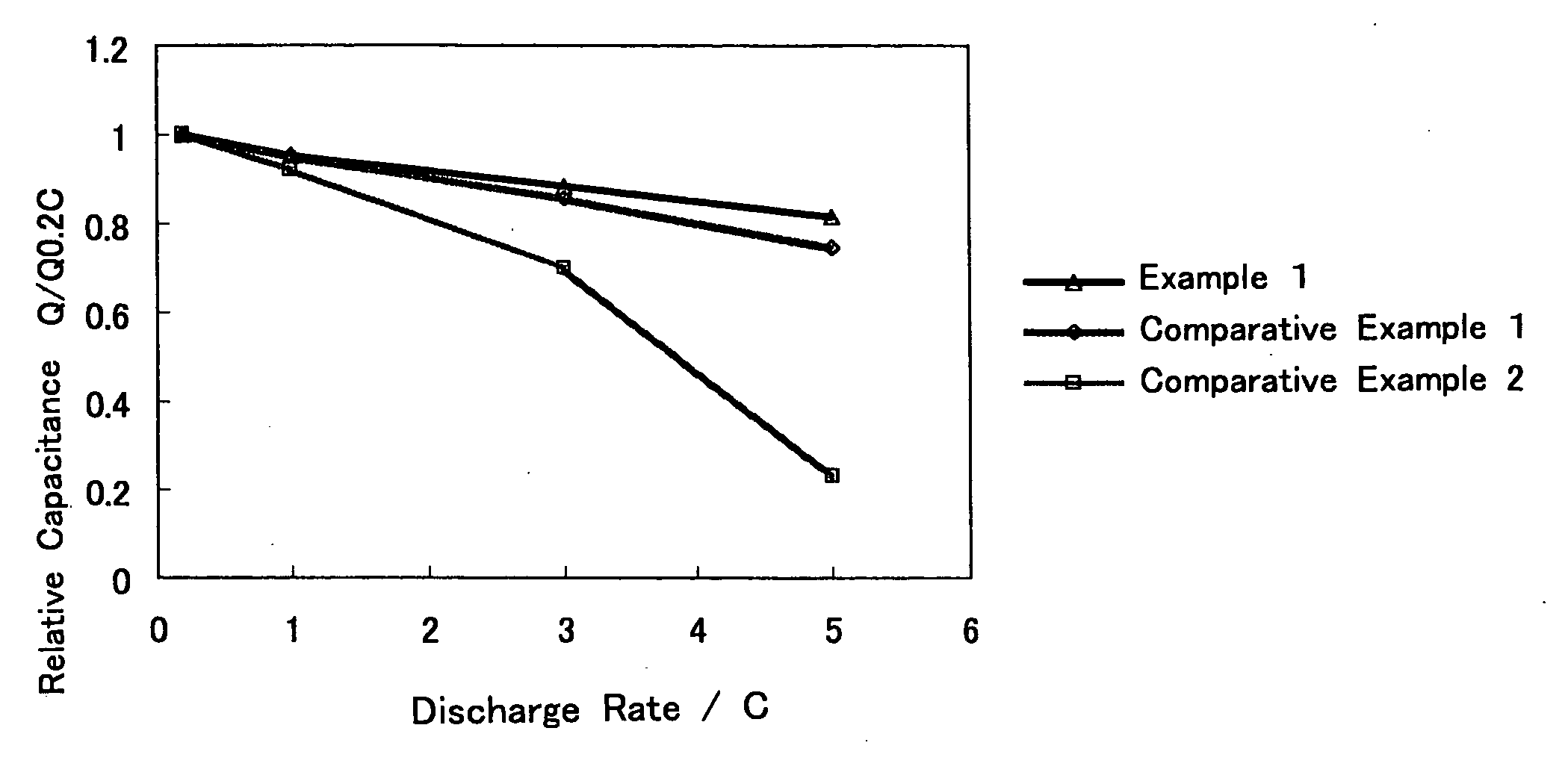

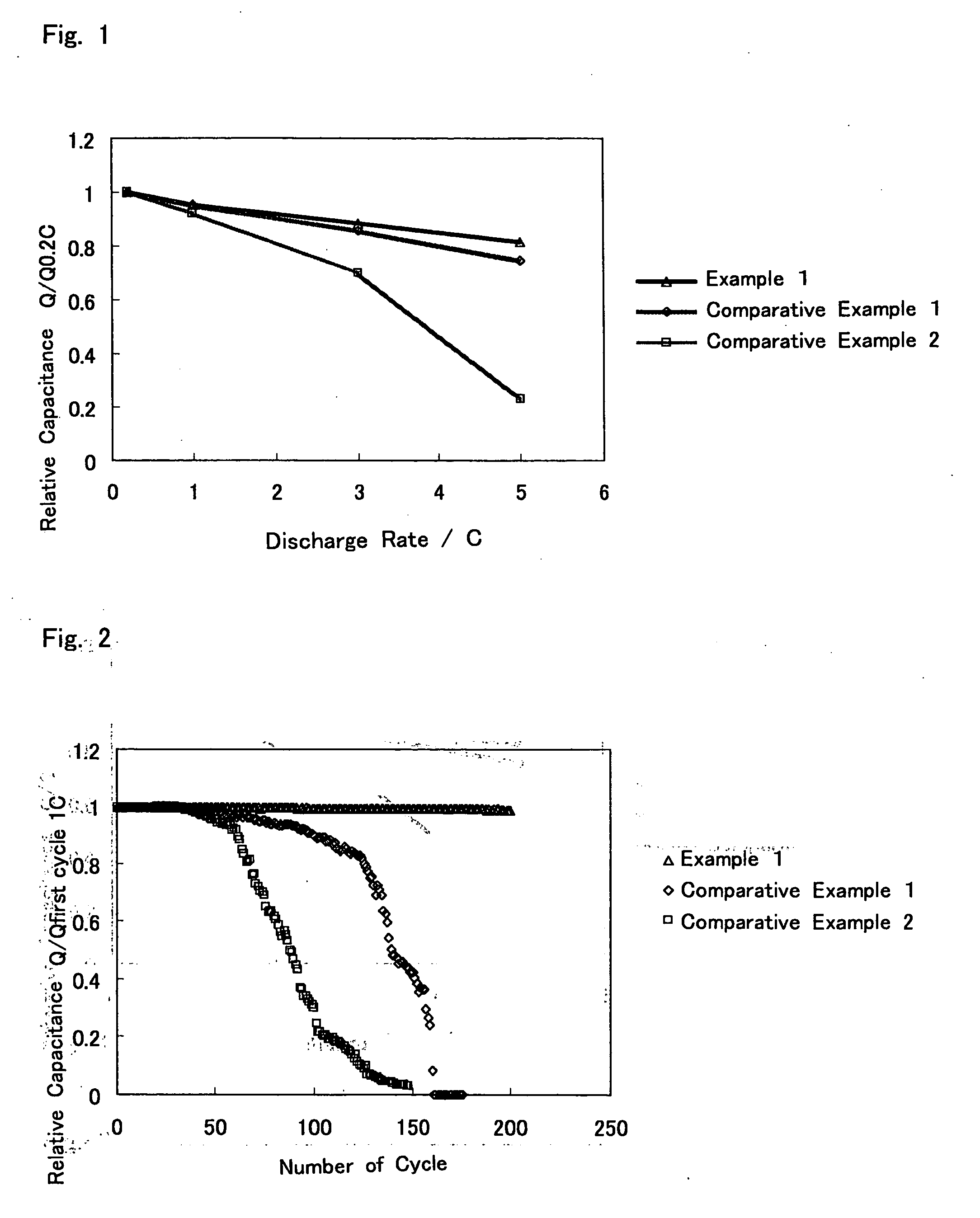

Examples

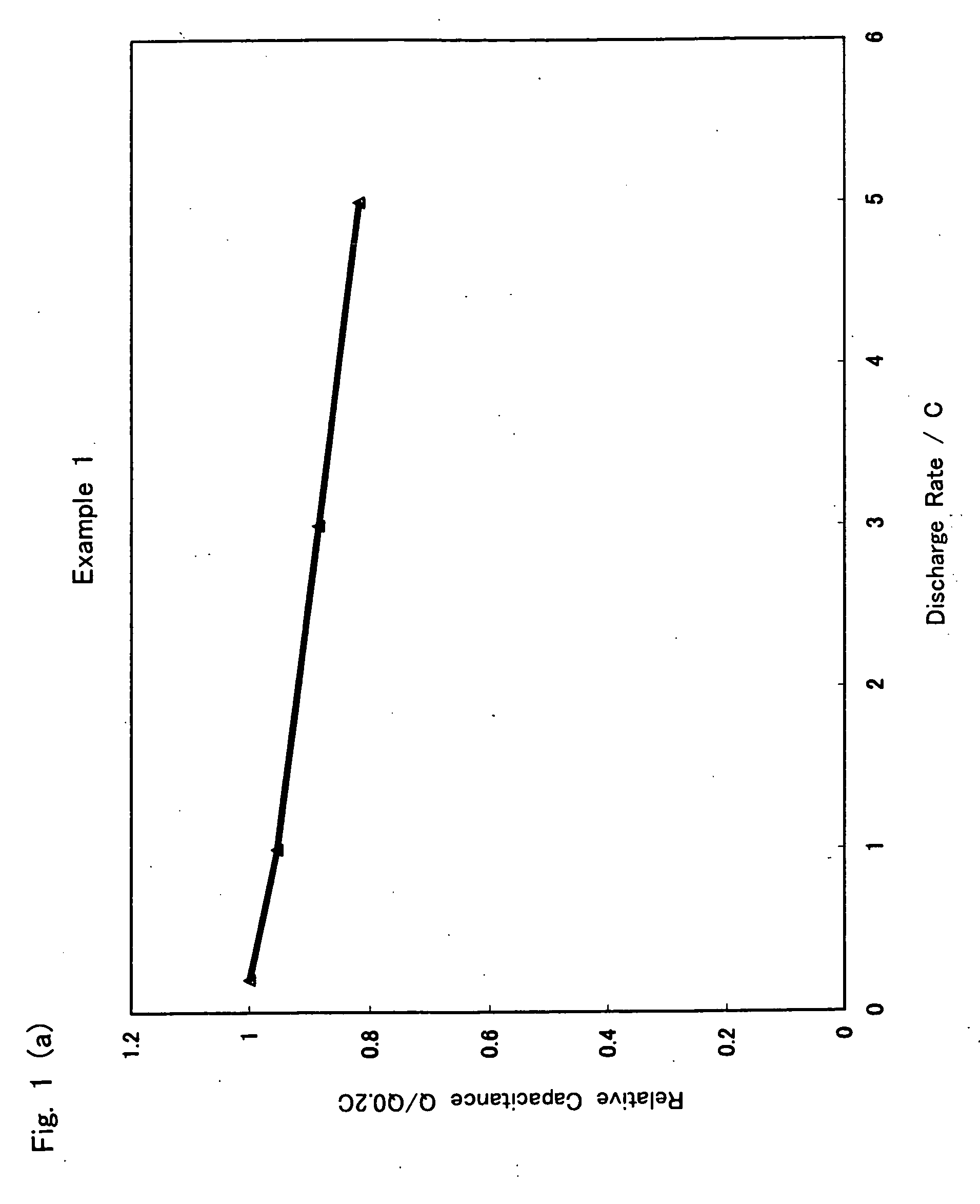

example 1

[0063] 100 g of LiFePO4 with 5% by weight of a carbon coating amount as a positive electrode active material, 10 g of acetylene black (manufactured by Denki Kagaku Kogyo Co.) as an electrically conducting agent, 120 g of an aqueous 2 wt % solution of carboxynethyl cellulose with an etherfying degree of from 0.45 to 0.55 (CELOGEN PL-15, manufactured by Daiichi Kogyo Seiyaku Co.) as a viscosity improver, and 0.5 g of a nonionic surfactant having a polyoxyethylene styrenated phenyl ether structure (trade name of products: NOIGEN EA-137, manufactured by Daiichi Kogyo Seiyaku Co.) as a dispersing agent were mixed by a homo-mixer for 30 min. 10 g of an aqueous 40 wt % solution of the SBR emulsion (trade name of products: MB-400B, manufactured by Nippon Zeon Co.) as a binder and 50 g of water as a dispersion medium were added to the mixed solution, stirred by a homo-mixer for 15 min and, further, mixed by a ball mill for 6 hours, to prepare a positive electrode paste.

[0064] The positive e...

example 2

[0069] 100 g of LiFePO4 with 2% by weight of a carbon coating amount as a positive electrode active material, 6 g of acetylene black (manufactured by Denki Kagaku Kogyo Co.) as an electrically conducting agent, 100 g of an aqueous 2 wt % solution of carboxymethyl cellulose with etherfying degree from 0.6 to 0.7 (CELOGEN WS-C, trade name of products, manufactured by Daiichi Kogyo Seiyaku Co.) and 1 g of a nonionic surfactant of a polyoxyethylene styrenated phenyl ether structure as a dispersing agent (NOIGEN EA-187, trade name of products manufactured by Daiichi Kogyo Seiyaku Co.) were mixed by a homo-mixer for 30 min. 5 g of a 40 wt % solution of an SBR einulsion (BM-400B, trade name of products manufactured by Nippon Zeon Co.) as a binder, and 50 g of water as a dispersion medium were added to the mixed solution, stirred by a homo-mixer for 15 min and, further mixed by a ball mill for 6 hours, to obtain a positive electrode paste.

[0070] The positive electrode paste was coated on a...

example 3

[0072] 100 g of LiCoPO4 with 5% by weight of a carbon coating amount as a positive electrode active material, 3 g of carbon black (trade name of products: Ketchen Black EC, manufactured by AKZO NOBEL Co.) as an electrically conducting agent, 100 g of an aqueous 1 wt % solution of carboxyrethyl cellulose with an etherfying degree of from 0.55 to 0.65 (CELOGEN 3H, manufactured by Daiichi Kogyo Seiyaku Co.) as a viscosity improver, and 2 g of a sodium naphthalene sulfonate formalin condensation product (trade name of products: Lavelin FM-P, Daiuchi Kogyo Seiyaku Co.) as a dispersing agent were mixed by a homo-mixer for 30 min. 7.5 g of an aqueous 40 wt % solution of an SBR emulsion (trade name of products: BM-400B, manufactured by Nippon Zeon Co.) as a binder and 50 g of water as a dispersion medium were added to the mixed solution, stirred by a homo-mixer for 15 min and, further, mixed by a ball mill for 6 hours, to prepare a positive electrode paste.

[0073] The positive electrode pas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com