Exhaust gas processing method and exhaust gas processing system

a processing method and exhaust gas technology, applied in the field of exhaust gas processing methods and systems, can solve the problems of ultra-fine particles with diameters of 2.5 m or smaller, which have recently become a problem on anti-pollution measures, and the need for filtering with extremely fine meshes, etc., to achieve easy and efficient collection of floating particulate matter, easy condense even a small amount, and low electric resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment 1

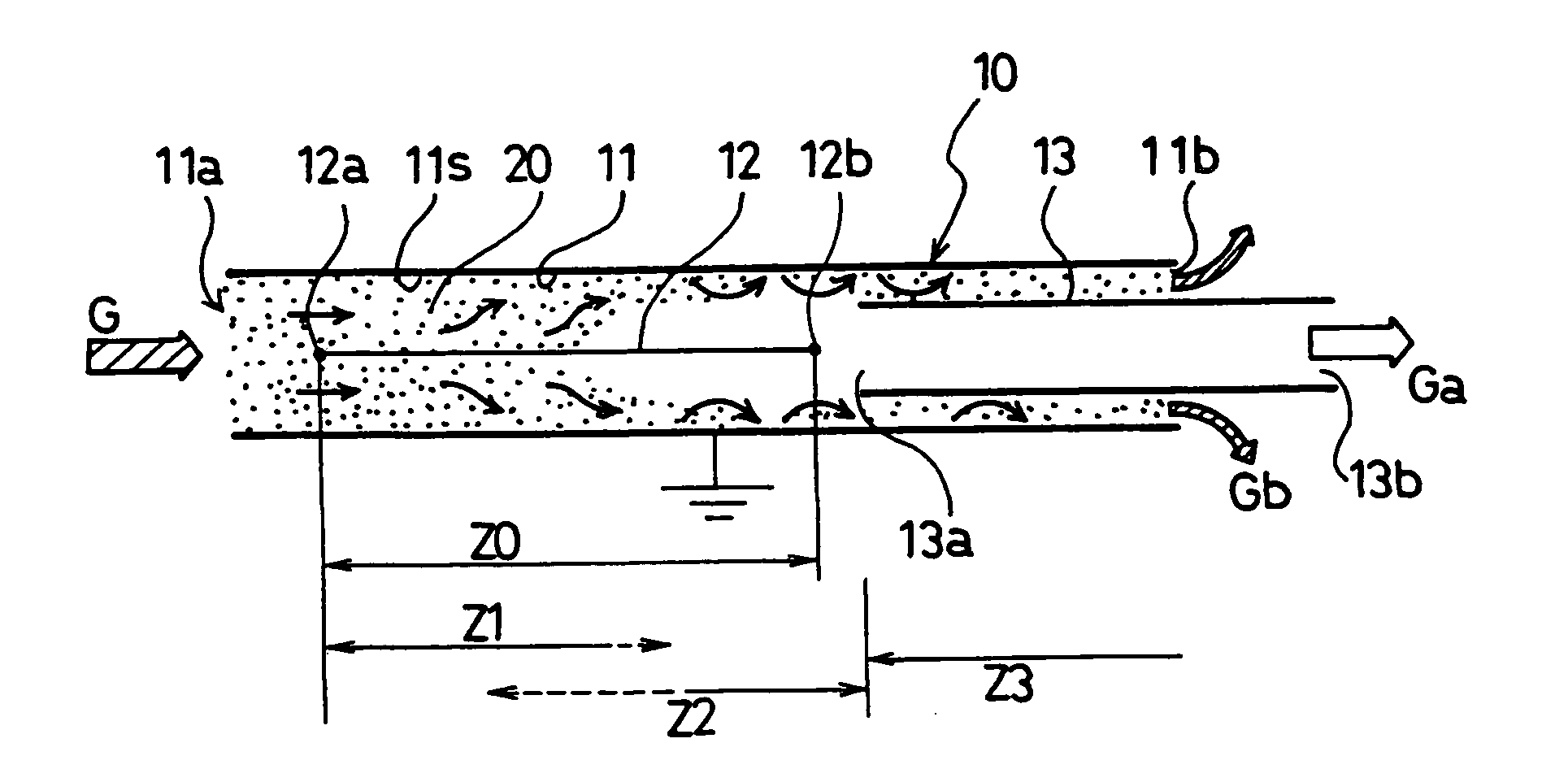

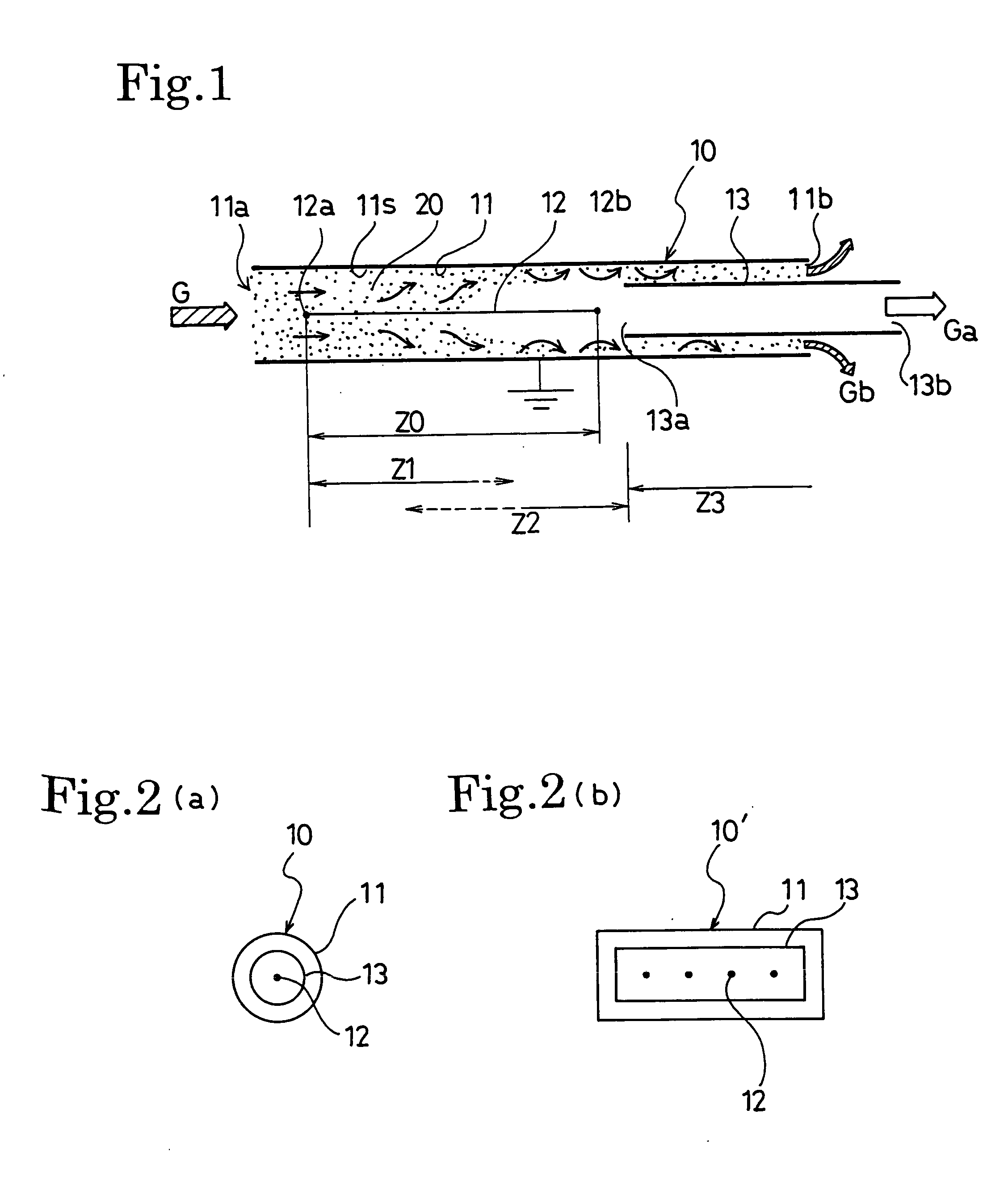

[0095] In the case of the exhaust gas processing system 10 of the first embodiment shown in FIGS. 1 and 2 (a), the high-voltage electrode 12 is formed of a stainless wire with a diameter of 0.2 mm φ, the low-voltage electrode 11 is formed by a stainless cylinder with an inside diameter of 38 mm φ, and the inner cylinder 13 is formed of a stainless cylinder with an inside diameter of 15 mm φ. The ratio between the inside and outside cross-sectional area of a cylinder becomes 5:3.

[0096] The exhaust gas processing system 10 is directly connected to the exhaust gas pipe area of a small diesel power generator (maximum output of 5 kW) to perform an experiment under an operation condition at 2.4 kW (48%) load. A voltage of −10 kV and a current of 0.4 mA are supplied to a high-voltage electrode by using a negative electrode direct high voltage power supply. The temperature of the exhaust gas processing system 10 is set to 100-200° C., flow rate of exhaust gas is set to approx. 200 L / min (i...

embodiment 2

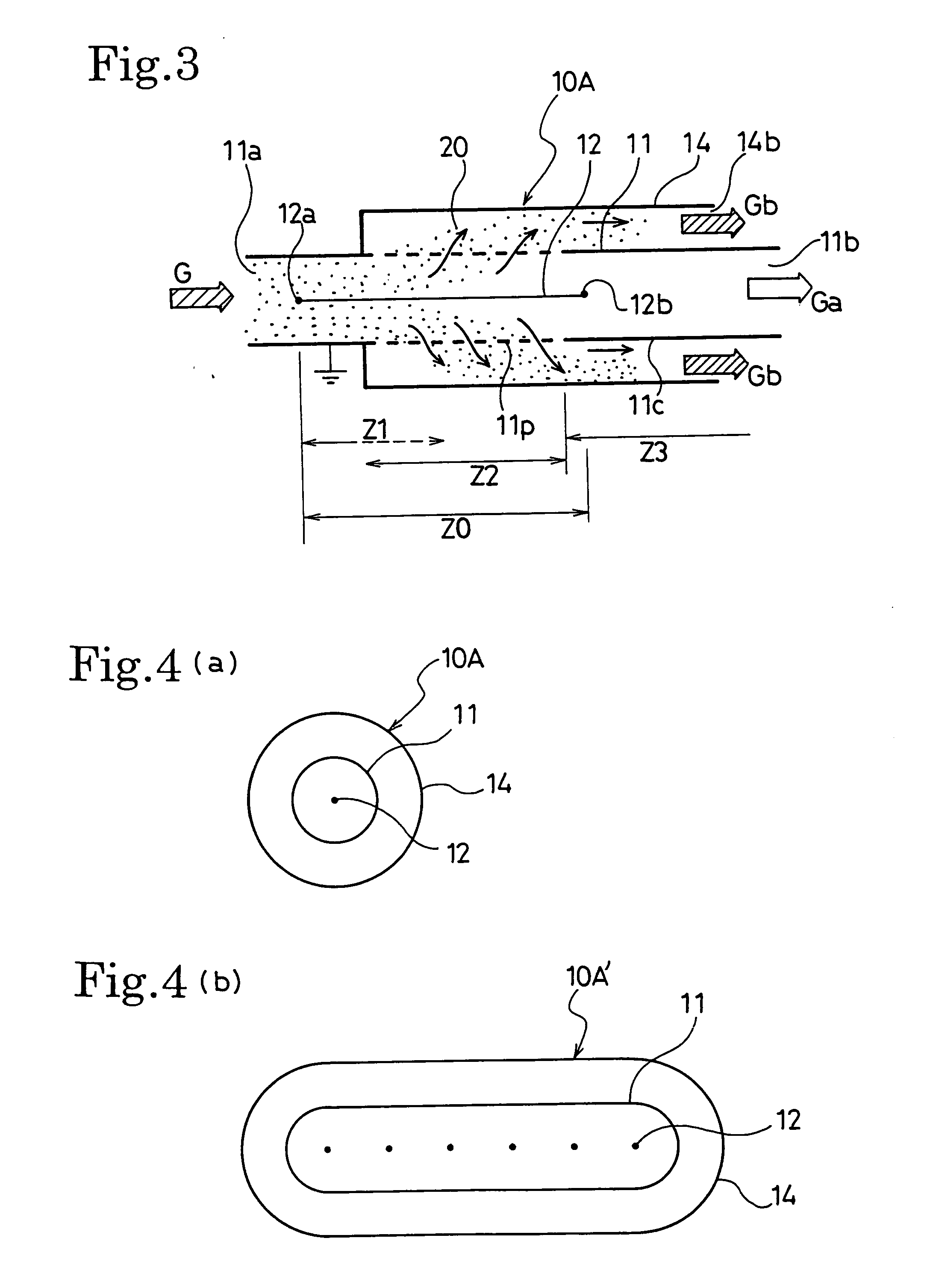

[0100] In the case of the exhaust gas processing system 10C of the fourth embodiment shown in FIGS. 6 and 7 (a), the high-voltage electrode 12 is formed of a stainless wire with a diameter of 0.6 mm φ, the low-voltage electrode 11 is formed of a stainless cylinder with an inside diameter of 58 mm φ, and the outer cylinder 14 is formed of a stainless cylinder with an outside diameter of 220 mm φ. The filter 16 is provided to three layers by punching metal with a pore diameter of 1 mm at 2-mm pitch.

[0101] The exhaust gas processing system 10C is directly connected to the exhaust gas pipe area of a 2-ton truck to perform an experiment under conditions of an engine speed of 550 rpm, exhaust gas temperature of approx. 70° C., and exhaust gas quantity of approx. 1,400 L / min. A voltage of −18 kV is applied to a high-voltage electrode by using a negative electrode direct high voltage power supply. The retention time at the electrifying area (length of 300 mm) is approx. 30 ms and the reten...

embodiment 3

[0104] In the case of the exhaust gas processing system 10D of the fifth embodiment shown in FIG. 8, an experiment is performed in the same dimension and condition as the case of the embodiment 2 to collect the PM in exhaust gas by using glass fiber filter paper having a 0.3 μm φ particle with capturing rate of 99.9% or more and aspirating the re-merging exhaust gas Gc by a constant-flow-rate pump.

[0105] As a result, a clear difference between the cases of presence of discharge and absence of discharge is observed in the filter paper through which the exhaust gas Gc passes. Thereby, it is found that the PM is extremely decreased by applying a voltage to a corona discharge electrode.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com