Chalcogenide devices incorporating chalcogenide materials having reduced germanium or telluruim content

a technology of chalcogenide materials and chalcogenide devices, which is applied in the direction of bulk negative resistance effect devices, basic electric elements, electric devices, etc., can solve the problems of affecting the stability of the material, the material needs to be thermally stable, and the material is susceptible to variations in the structural state, so as to achieve sufficient thermal stability, improve the thermal stability of data retention, and achieve sufficient thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

[0048] In this example, the fabrication of memory devices having active chalcogenide layers in accordance with the instant invention is described. The device structure is a commonly utilized two-terminal device design having an active chalcogenide layer in a pore geometry in electrical contact with top and bottom electrodes. Two different device configurations were used and similar results were achieved for each. Both designs were deposited on an Si wafer with a thick SiO2 surface oxide layer.

[0049] In one design, a tungsten layer was deposited on the surface oxide and another SiO2 layer was deposited thereon. A 600 Å diameter opening was formed in the deposited SiO2 layer and was filled with TiN. The tungsten layer and TiN layers serves as a bottom electrode. A chalcogenide layer having a thickness of 500 Å was deposited on the TiN filled opening and surrounding SiO2 layers. A top electrode was next deposited in situ and included a 400 Å carbon layer deposited on top of the chalco...

example 2

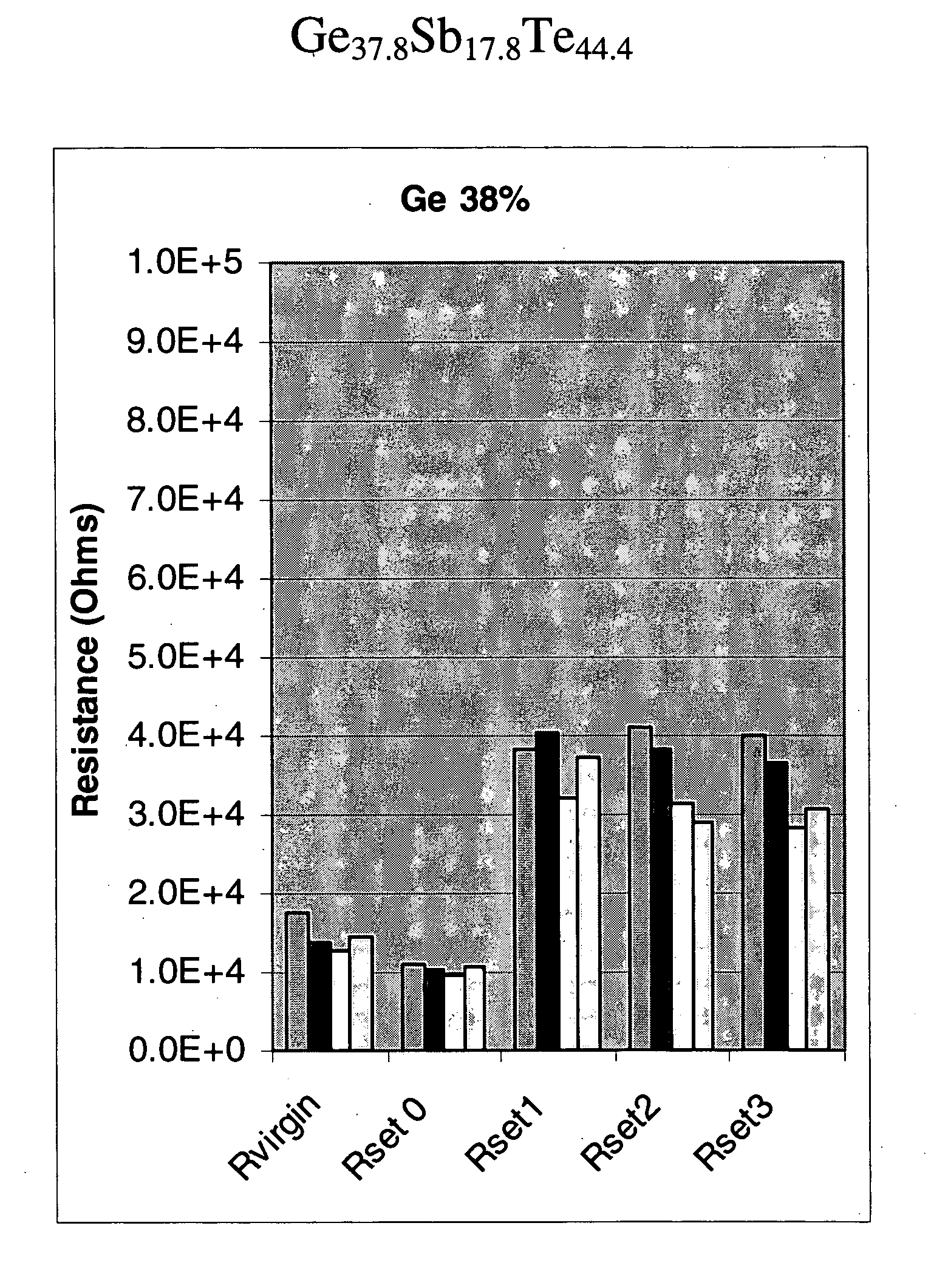

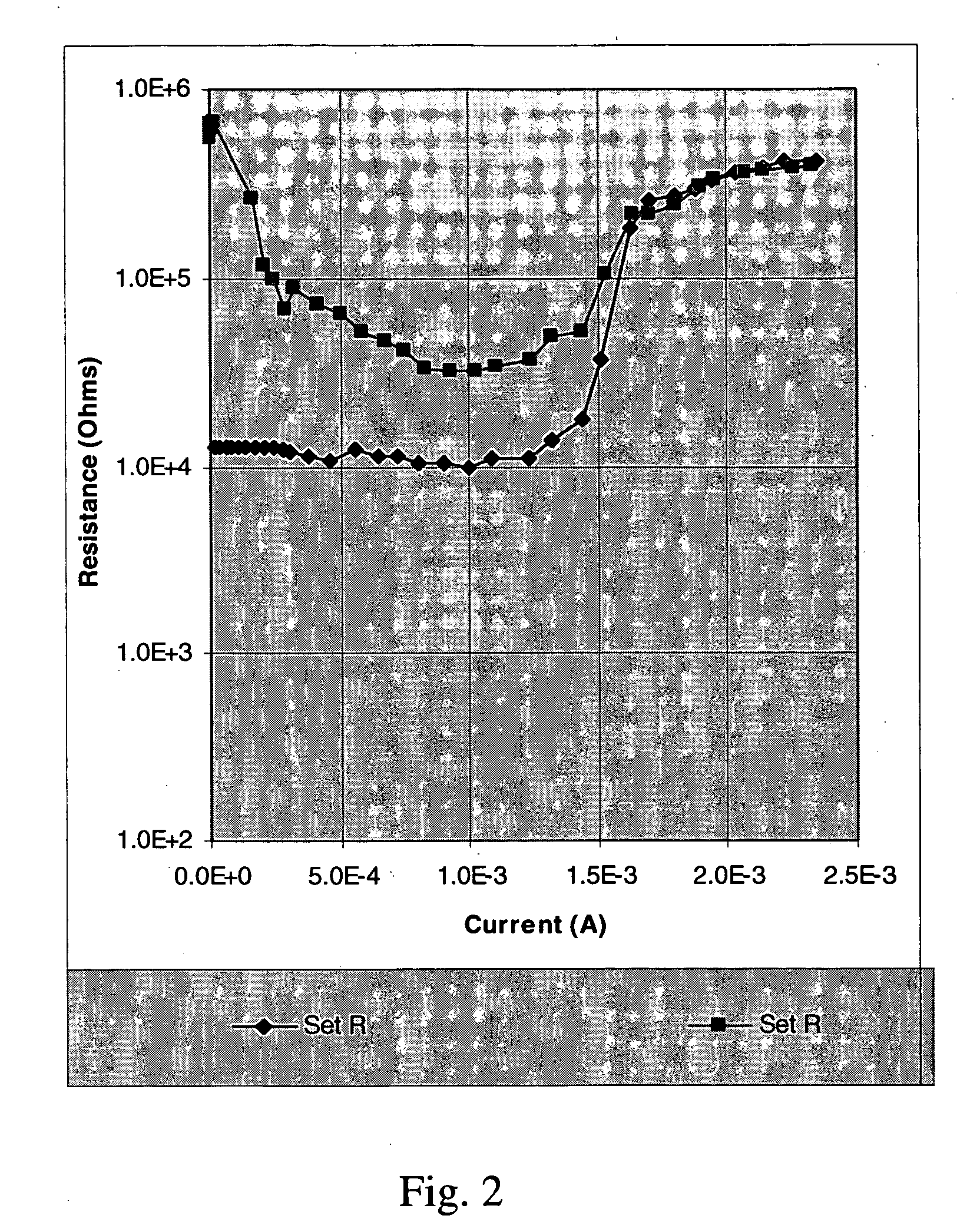

[0053] In this example, the improved formation characteristics of devices according to the instant invention are described. As described hereinabove, formation is a process that involves the post-fabrication electrical conditioning of a device to prepare it for its end application. Formation is required for the currently available chalcogenide memory devices and requires a series of electrical conditioning cycles that include setting and resetting the device until stable resistances are achieved for the set and reset states. In this example, we demonstrate the ability of devices using the instant chalcogenide materials to reduce or eliminate the need for formation. The devices used in this example correspond to those described in EXAMPLE 1 hereinabove. Devices included selected chalcogenide compositions from those presented in EXAMPLE 1 are described.

[0054] To evaluate the formation requirements of a device, we measured the resistance of the device in its as-fabricated state and su...

example 3

[0070] In this example, the speed advantage of the instant devices is demonstrated. During operation of a memory device, it is necessary to program the device into and out of the set and reset states in most applications. Since establishment of the reset state can generally be accomplished on shorter time scales than establishment of the set state, the programming speed of the device is controlled by the time required for setting. (Typically, the time required to set (time-to-set) is a factor of 10 or more greater than the time to reset.) Since the time-to-set is governed by the underlying crystallization process, it is desirable to develop chalcogenide materials suitable for use in memory devices that exhibit fast crystallization so that the set speed of the device can be shortened. The devices used in this example correspond to those described in EXAMPLE 1 hereinabove. Devices included selected chalcogenide compositions from those presented in EXAMPLE 1 are described.

[0071] In th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com