Anion adsorbing carbon material, as well as manufacturing method and manufacturing facilities for same

a technology of carbon materials and anions, applied in the field of anion adsorption carbon materials, can solve the problems of contaminating water quality and soil, destroying the environment, and presently difficult to treat anions in the form of anions with adsorbents,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

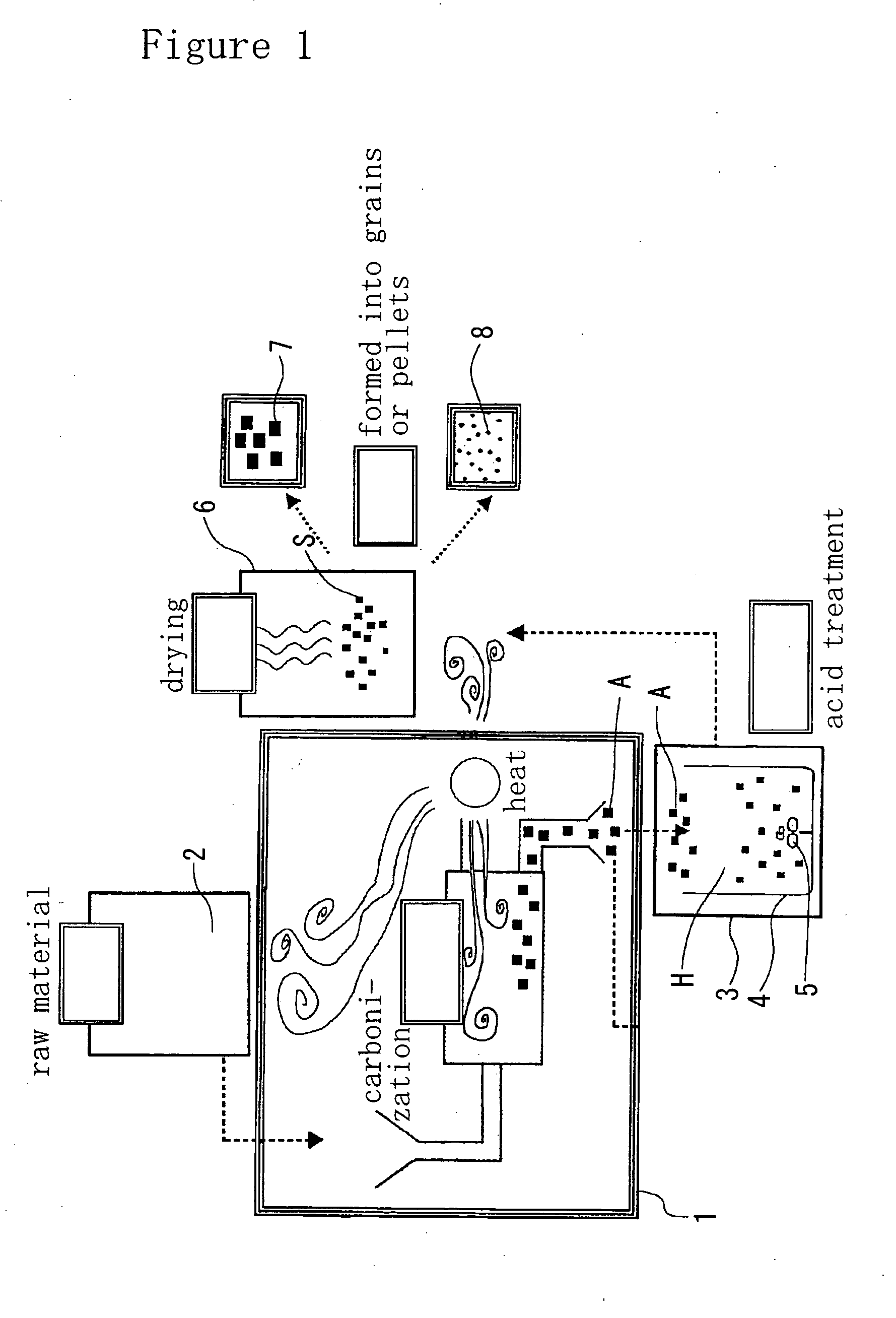

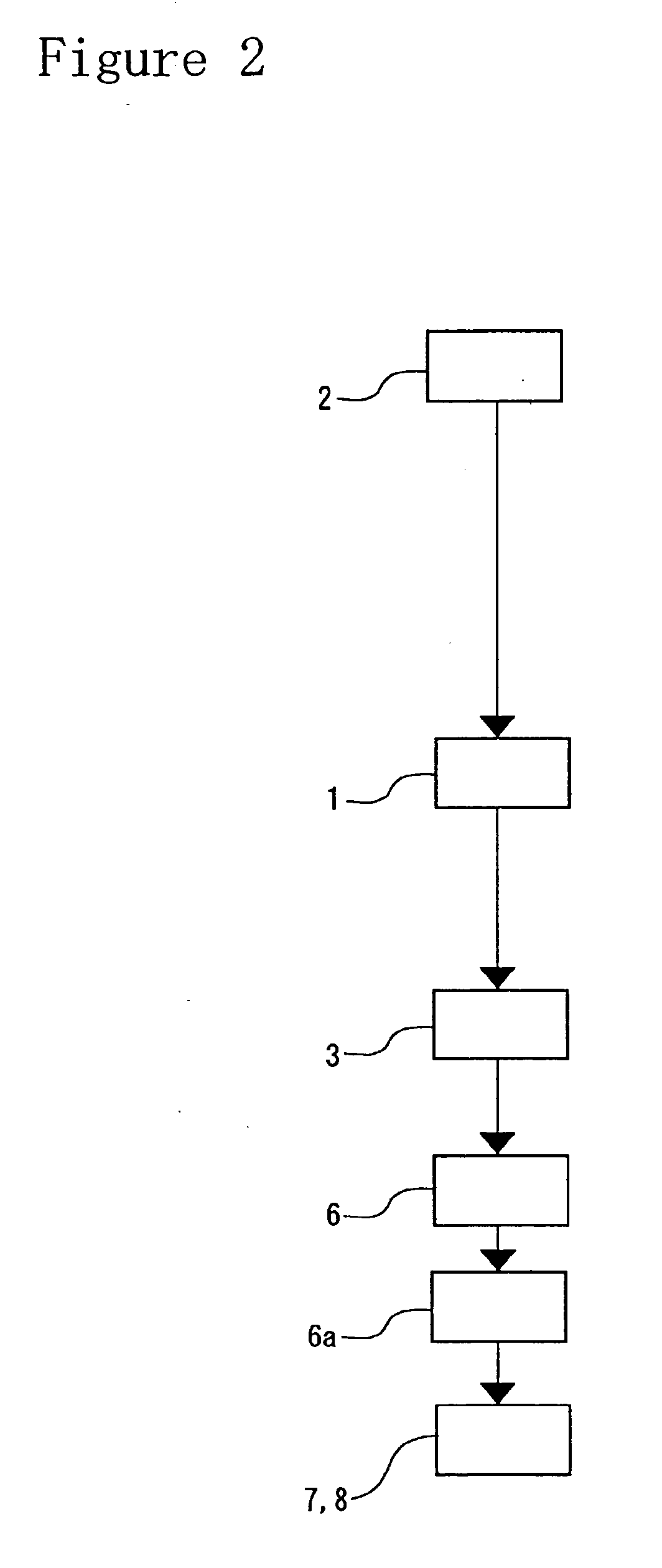

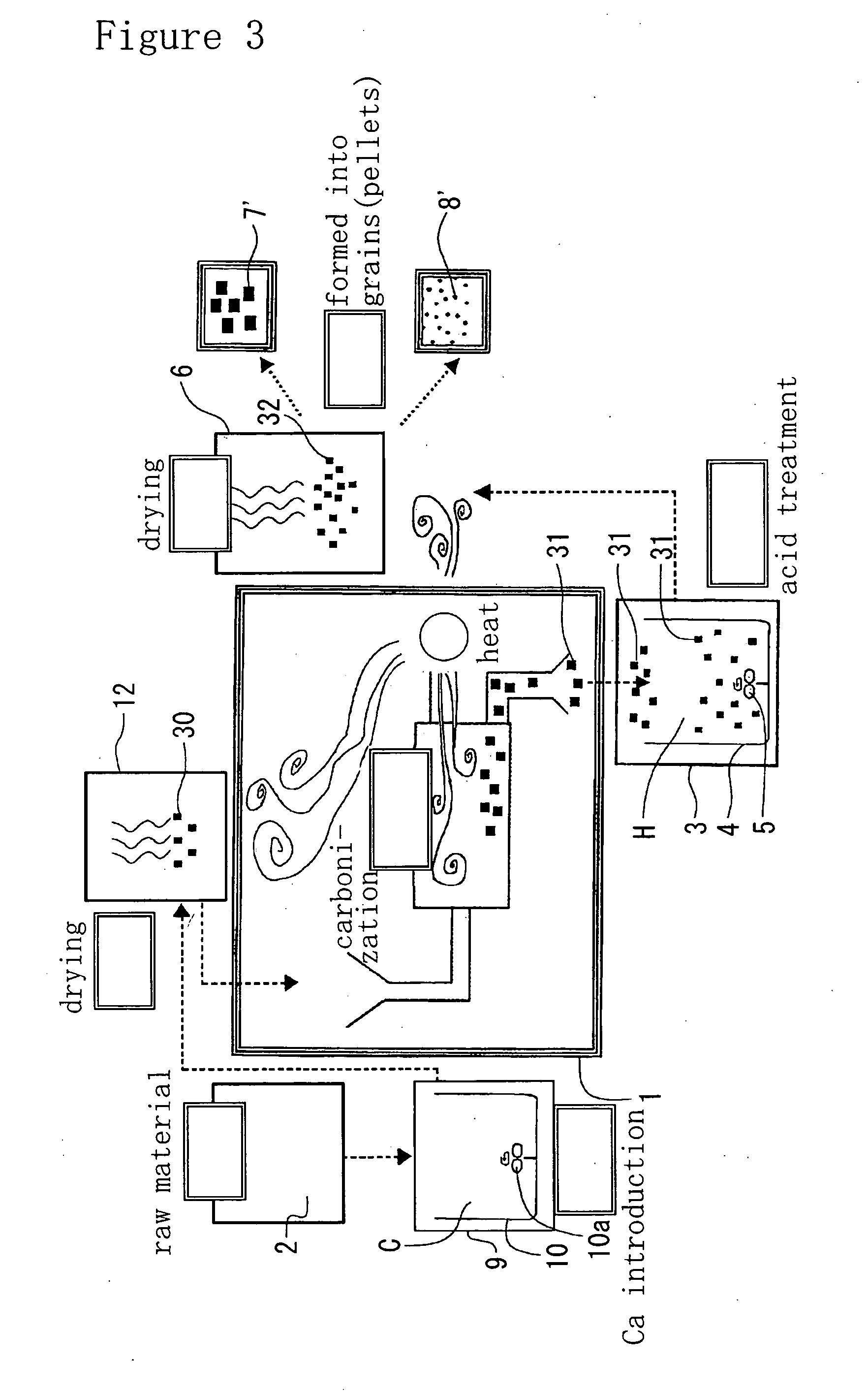

[0106]FIGS. 1 and 2 show this invention.

[0107] In FIGS. 1 and 2, 1 indicates a carbonization furnace (an example of a carbonization apparatus for carbonizing a raw material which comprises plant(s)) for carbonizing a ligneous material (an example of a raw material which comprises plant(s)) 2 of plant(s), for example, natural fibers, including hemp, or lumber, without activating the material. Ligneous chips, for example, are used as the above described material 2. These ligneous chips are gained by processing a conifer, such as Japanese cypress or cedar having high water absorbency and have a size of no greater than, for example, 10 mm.

[0108]3 indicates facilities for acid treatment which contact an acid solution with a carbonized material that has been created by carbonization apparatus 1, and has mixing blades 5 inside a container 4 for containing an acid solution H, for example, HCl and H2SO4. The concentration of this acid solution is, for example, 5 mol / L. Apparatus for acid tr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com