Tri-excluded WUCS glass fiber reinforced plastic composite articles and methods for making such articles

a technology of glass fiber reinforced plastic and composite articles, which is applied in the direction of textiles and papermaking, transportation and packaging, textiles, etc., can solve the problems of less suitable products for forming composite products, products generally unsuitable for articles subjected to bending, and the thickness and length of wood fiber and strand typically utilized in producing osb products are generally less suitable for products, so as to achieve a reduced or optimal level of incorporation, improve the performance of products, and effectively enhan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

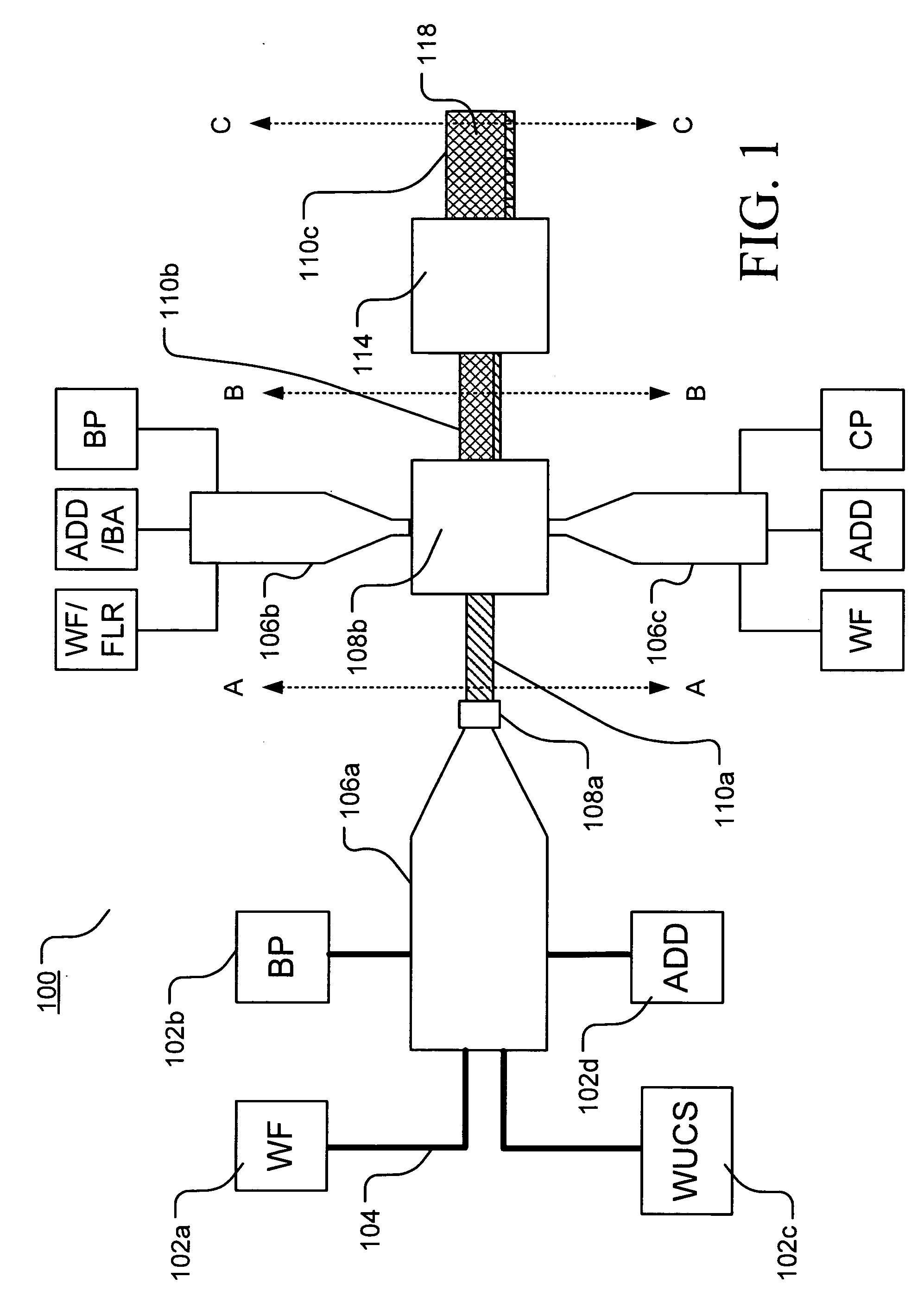

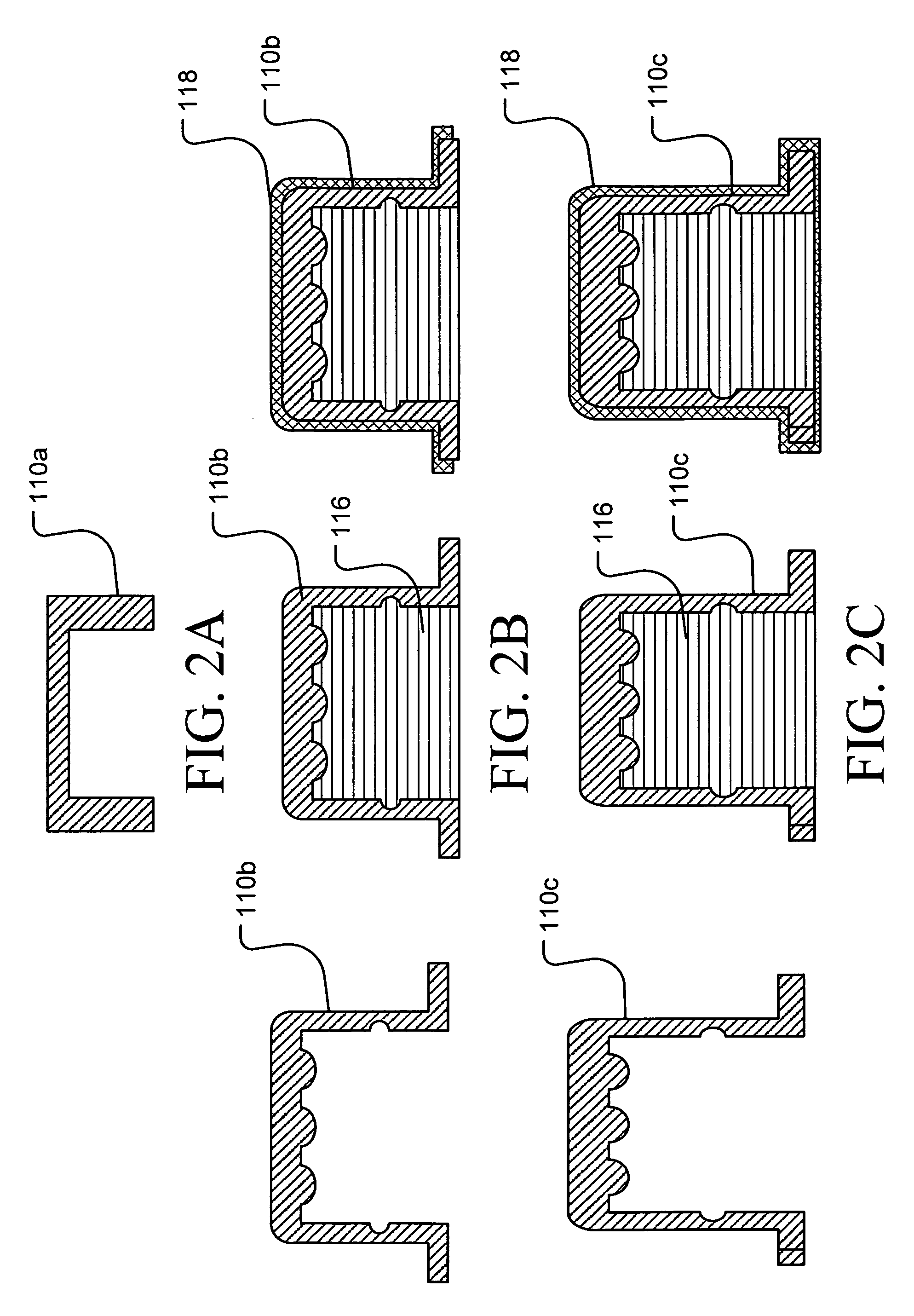

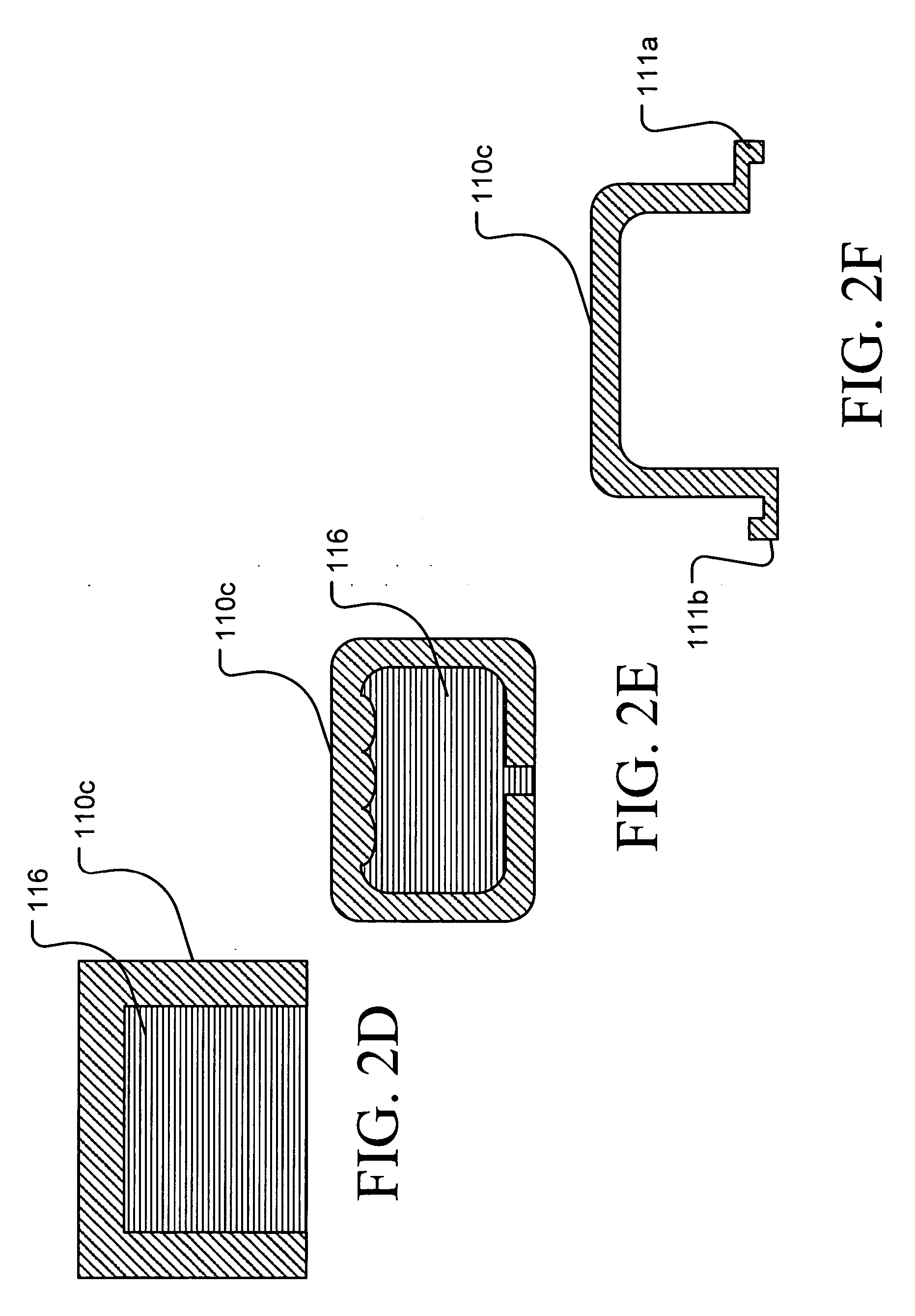

[0073] Illustrated in FIG. 1 is an example of a manufacturing line according to an embodiment of the invention in which various components such as wood fibers (WF) 102a, base polymers (BP) 102b, wet use chopped strand fiberglass (WUCS) 102c and other additives (ADD) 102d are provided through feed lines 104 to a blender / extruder mechanism 106a. Similar blender / extruder mechanisms 106b and 106c may be used to prepare one or more additional compositions for combination with the primary structure or initial form 110a as it is extruded from die 108 or shortly thereafter to fabricate a composite article. The other compositions may be prepared in the blender / extruder mechanisms 106b, 106c to form uniform mixtures having a suitable temperature and viscosity and then extruding the mixture through one or more dies included in apparatus 112 to form an initial form 110a. An example of a cross-section of initial form 110a along plane A-A is illustrated in FIG. 2A.

[0074] As suggested in FIG. 1, ...

second embodiment

[0077] Illustrated in FIG. 3 is an example of a manufacturing line according to another embodiment of the invention in which various components such as wood fibers (WF) 202a, binders and / or polymers (BP) 202b, fiberglass reinforcement (WUCS) 202c and other additives (ADD) 202d are provided through feed lines 204 to a blender / extruder mechanism 206. The various components are combined in the blender / extruder mechanism 206 to form a uniform mixture having a suitable temperature and viscosity and then extruding the mixture through a die 208 to form an initial form 210a. An example of a cross-section of initial form 210a along plane A-A is illustrated in FIG. 4A.

[0078] If desired, the initial form 210a may then be subjected to additional heating and / or forming operations in unit 212 to modify the initial form an produce an intermediate form 210b having a more complex cross-sectional profile. An example of an intermediate form 210b is illustrated in FIG. 4B. As illustrated in FIG. 3, a ...

third embodiment

[0080] Illustrated in FIG. 5 is an example of a manufacturing line according to another embodiment of the invention in which various components such as wood fibers (WF) 302a, binders and / or polymers (BP) 302b, fiberglass (WUCS) 302c and other additives (ADD) 302d are provided through feed lines 304 to a blender / extruder mechanism 306a. The various components are combined in the blender / extruder mechanism 306a in different proportions to form at least two separate and distinct compositions at suitable temperatures and viscosities for extrusion processing. The two compositions are then extruded through a die 308a to form an initial form 310a in which a first composition 314 forms a primary structural frame for the final product with a second composition 316 at least partially filling recesses defined in the primary structural frame form. An example of a cross-section of initial form 310a along plane A-A is illustrated in FIG. 6A in which the first composition 314 is extruded as a clos...

PUM

| Property | Measurement | Unit |

|---|---|---|

| weight | aaaaa | aaaaa |

| roughness | aaaaa | aaaaa |

| abrasion resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com