Two-part sizing composition for reinforcement fibers

a technology of sizing composition and reinforcement fiber, which is applied in the direction of fibre treatment, textiles and papermaking, transportation and packaging, etc., to achieve the effects of improving hydrolysis resistance, high loss-on-ignition (loi), and improving mechanical properties of dry as-molded

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples

[0079] Two-Part Sizing Formulations

TABLE 2Ex.Ex.Ex. 1Ex. 2Ex. 3Ex. 4Ex. 5Ex. 6Ex. 7Ex. 8Ex. 91011Size CompositionAX-1100 Silane(a)0.070.070.070.040.040.040.040.040.070.060.06Lubesize K-12(b)0.02Zonyl FS-300(c)0.005Baybond PU403(d)0.310.310.310.310.18Witcobond 296B(e)0.530.530.53Baybond XP-2602(f)0.160.16Binder CompositionGlascol E5(g)0.280.400.650.950.14Glascol C95(h)0.040.12ZeMac E400(i)0.300.240.470.38ZeMac E60(j)0.40AmmoniaBaybond PU-403(d)0.40Baybond XP-2602(e)0.21Aquathane 518(k)0.19AX-1100 Silane(a)0.02Jeffamine ED2003(l)0.09Pluronic F-77(m)0.0008Pluronic PE-103(n)0.0022Pluronic L-101(o)0.0009Triton X-100(p)0.0022Polyacid LOI0.000.280.300.000.400.650.950.280.610.400.50Total LOI (%)0.600.880.900.750.750.951.300.650.860.830.72

(a)AX-1100 Silane γ-aminopropyltriethoxysilane (GE Silicones)

(b)K12 Lubesize tetraethylenepentamine reacted with stearic acid (AOC)

(c)Zonyl FS-300 fluoroalkyl alcohol substituted polyethylene glycol (DuPont)

(d)Baybond PU-403 blocked isocyanate polyuret...

preparation of examples 1-3

of Table 2

[0081] In Examples 1-3, the components of Table 3 were mixed to prepare the size composition. The size composition was applied to 10 μm Advantex® glass fibers to achieve a strand Loss-On-Ignition (LOI) of 0.60% on the glass fibers. A conventional loss on ignition (LOI) method, ASTM 2854, was used to determine how much of the applied size composition was on the glass fibers. The glass fibers were then collected into a strand and chopped wet in-line by a chopper into segments of approximately 4 mm in length.

TABLE 3ComponentAmount of ComponentWitcobond 296B(a) 78.4 kg as received in 400 L of deionized waterAX-1100 Silane(b)19.91 kg as received in 500 L of deionized waterDeionized Waterto 1000 L

(a)blocked polyurethane dispersion (Baxenden Chemicals)

(b)γ-aminopropyltriethoxysilane (GE Silicones)

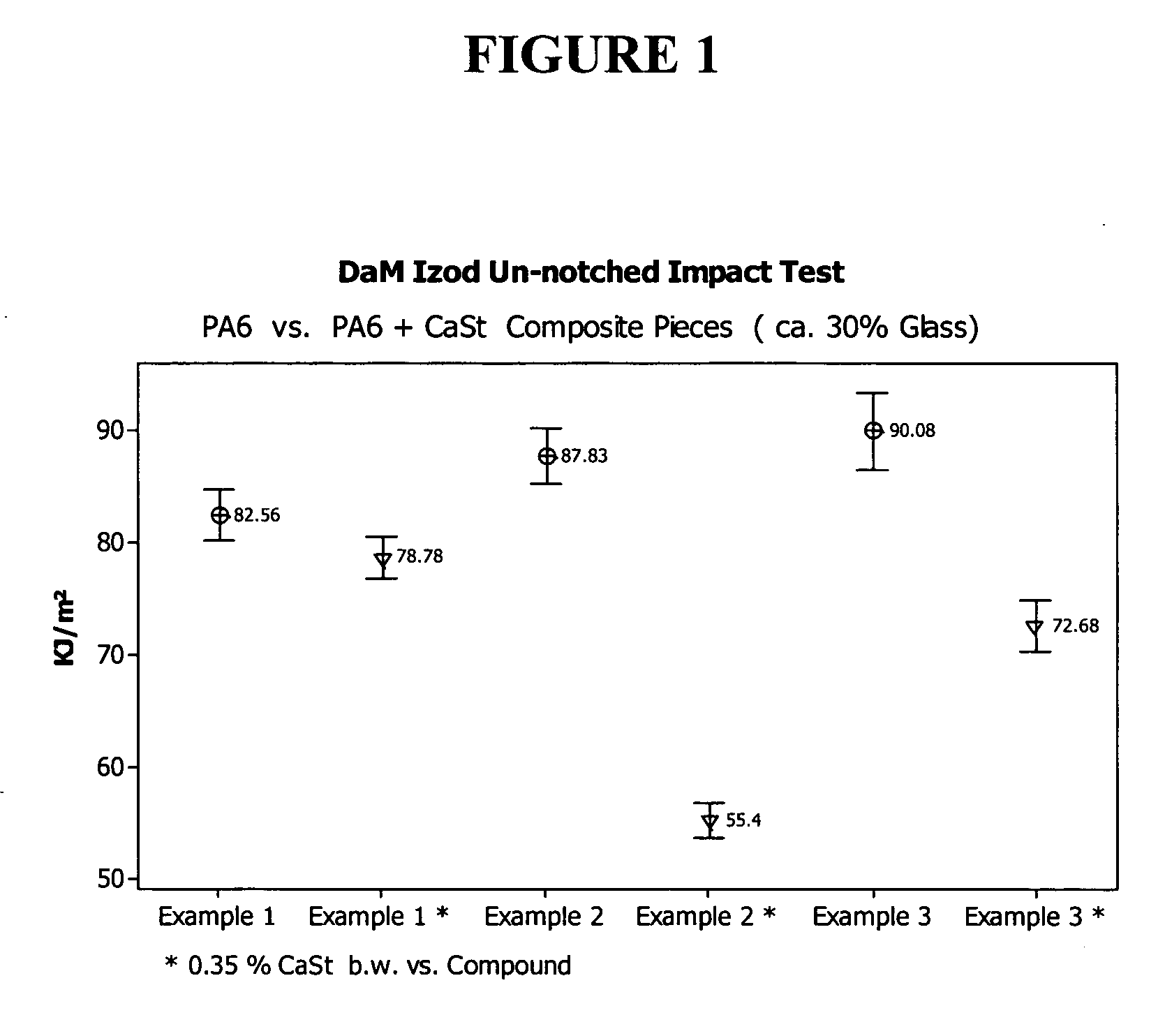

[0082] The chopped segments were then collected and approximately 1-2 days later treated under rotation in a lab pelletizer where the corresponding binder set forth in Table 2 was sp...

preparation of examples 4-7

of Table 2

[0083] In Examples 4-7, the components of Table 4 were mixed to prepare the size composition. The size composition was applied to 10 μm Advantex® glass fibers to achieve a strand Loss-On-Ignition (LOI) of 0.35% on the glass fibers. A conventional loss on ignition (LOI) method, ASTM 2854, was used to determine how much of the applied size composition was on the glass fibers. The glass fibers were then collected into a strand and chopped wet in-line by a chopper into segments of approximately 4 mm in length.

TABLE 4ComponentAmount of ComponentBaybond PU-403(a)160.20 kg as received in 450 L of deionized waterAX-1100 Silane(b) 14.5 kg as received hydrolyzed in 65 L ofdeionized waterDeionized Waterto 1400 L

(a)blocked isocyanate polyurethane dispersion (Bayer Corp.)

(b)γ-aminopropyltriethoxysilane (GE Silicones)

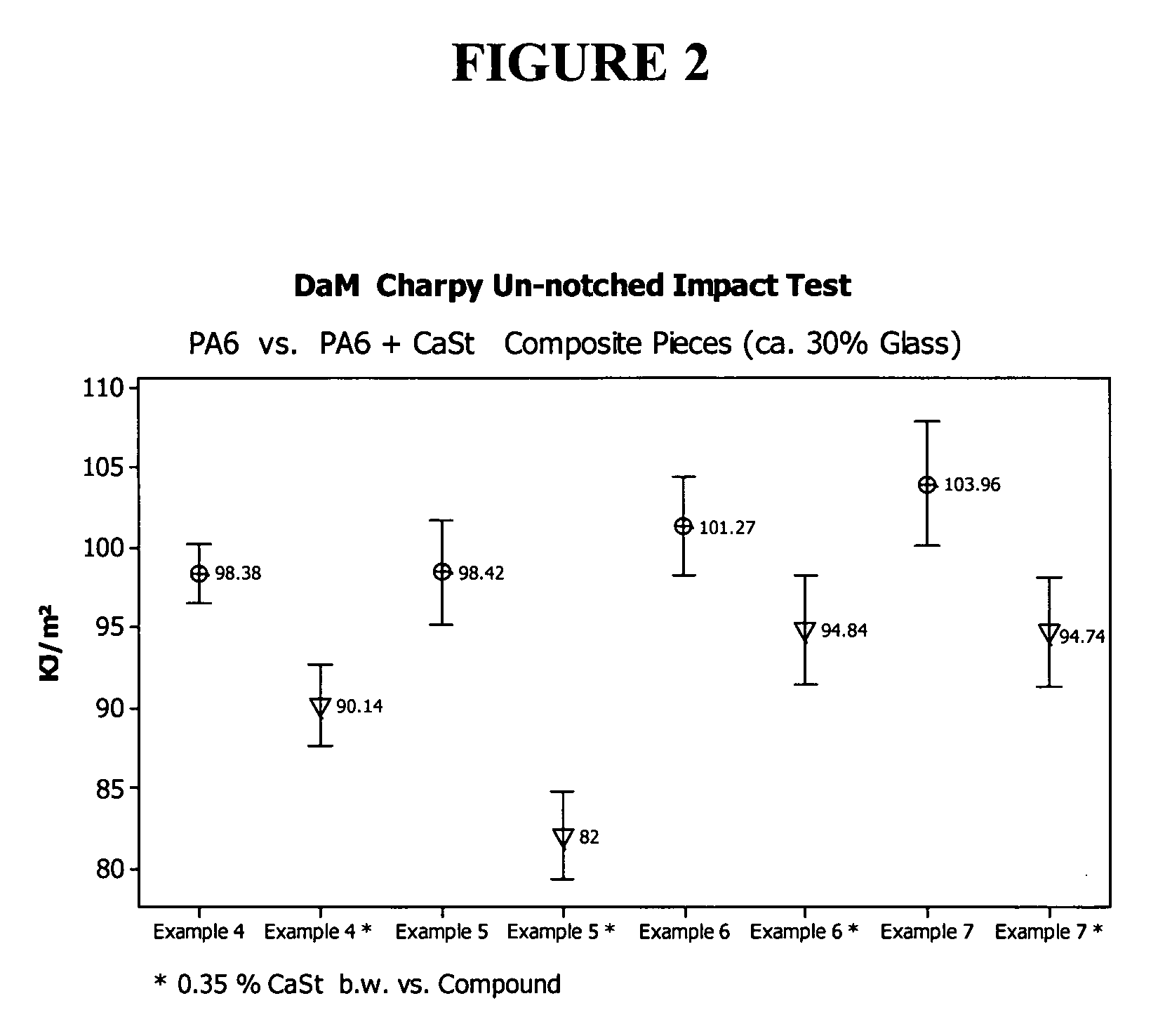

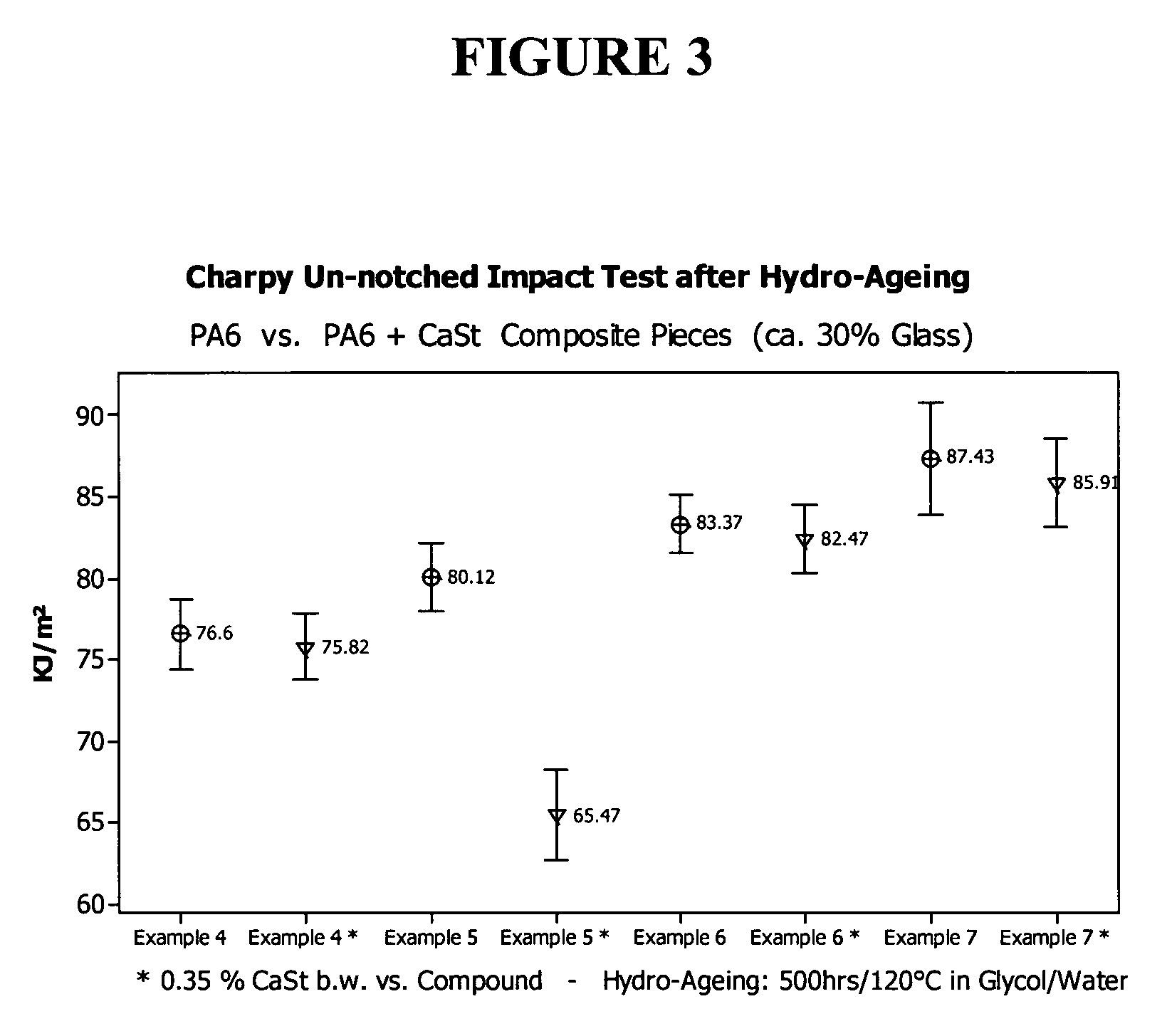

[0084] The chopped segments were then collected and approximately 1-2 days later treated under rotation in a lab pelletizer where the corresponding binder set forth in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com