Animal feed and methods for reducing ammonia and phosphorus levels in manure

a technology of animal feed and manure, which is applied in the field of animal feed and methods of feeding animals, can solve the problems of affecting the health and safety of people working in these environments, the odor control of poultry manure is continuing, and the ammonia content is particularly high, so as to reduce the ph of manure, reduce the number of insects associated, and reduce the volatile ammonia content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

experiment 1

[0079] In order to determine the efficacy of adding a high cation exchange capacity material pre-loaded with phosphate-reactive metals and acidogenic substances to animal feed rations, a test flock of white leghorn hens (HyLine W-36) was prepared. The test flock was subdivided into several units so that the effects of the various feed strategies could be monitored and compared. One unit acted as a control. This unit was fed a conventional industry standard diet, which initially comprised 18.8% by weight of crude protein, 4.2% by weight of calcium, and 0.5% by weight of bioavailable phosphorus. The conventional industry standard diet fed to the hens of this and the following examples as a control ration was substantially similar to the diet rations described in “Hy-Line Variety Commercial Management Guide 2003-2004” published by Hy-Line International, West Des Moines, Iowa, U. S. A. and available online at www.hyline.com.

[0080] A second unit was fed a ration of similar characteristi...

experiment 2

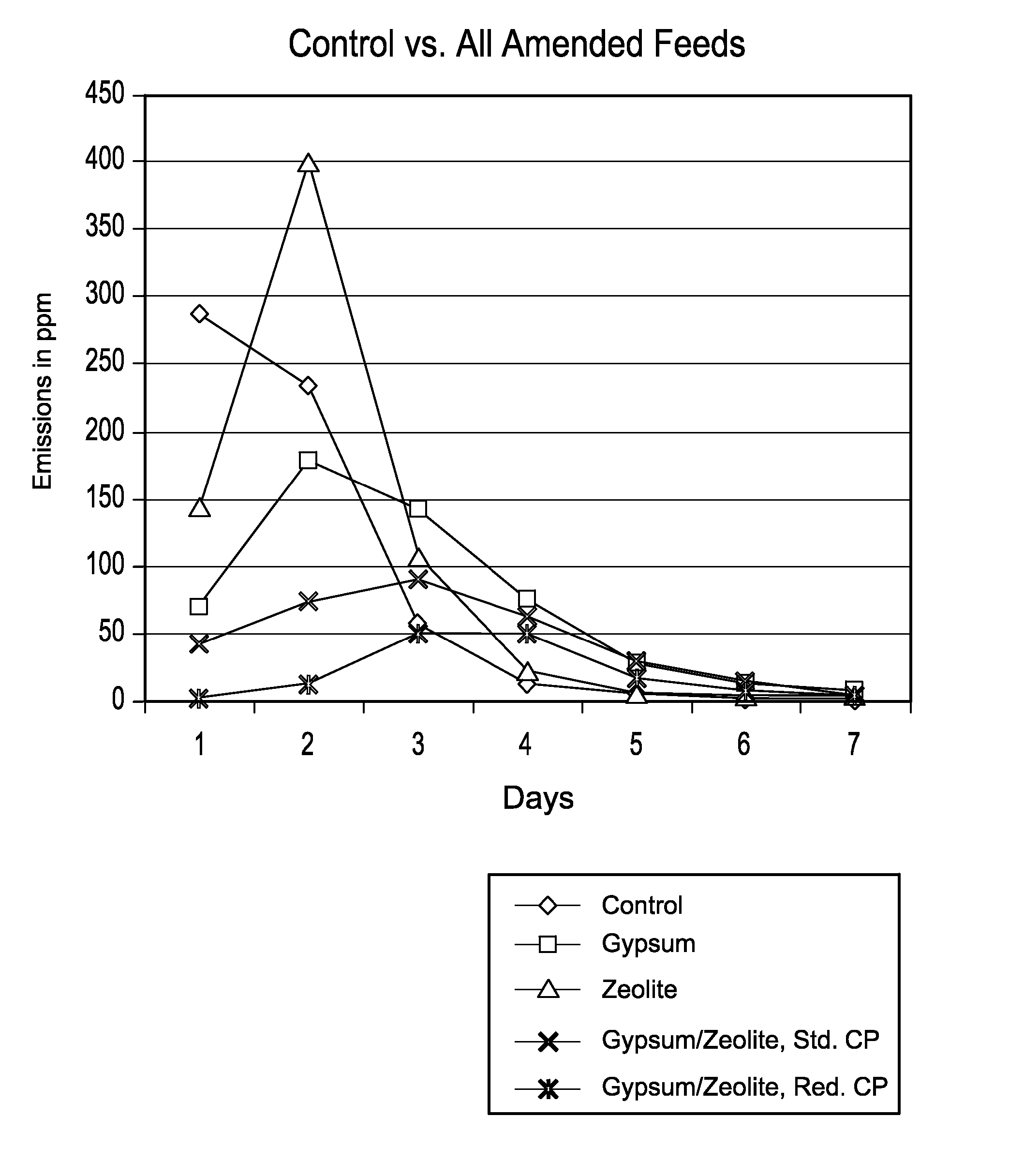

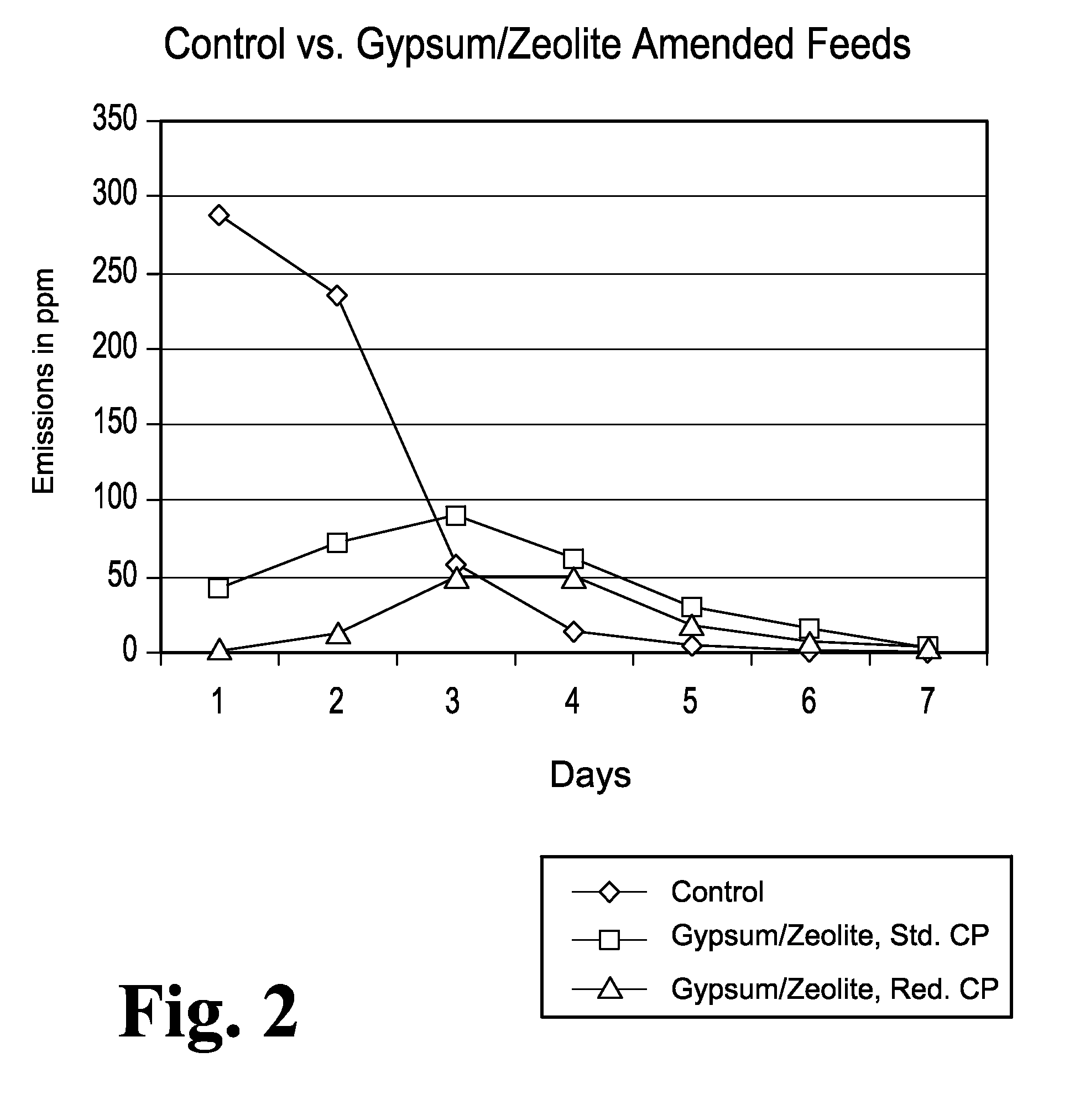

[0088] Manure produced by hens fed a ration that included the optimal amount of gypsum substituted for limestone was assayed less than 1 hour post-excretion. This manure was immediately transported to a laboratory, where the manure from each unit was homogenized and a 25-gram aliquot placed in a flask. The flask was supplied with air via an air pump. The air passed across the manure and collected the ammonia emitted. The ammonia-laden air was then bubbled through an acid solution to capture the ammonia. Every 24 hours, for a period of 7 days, the acid solution was changed out for fresh solution, and the samples were assayed to determine their levels of ammonia. Data resulting from the initial lab analyses are illustrated in Table 1.

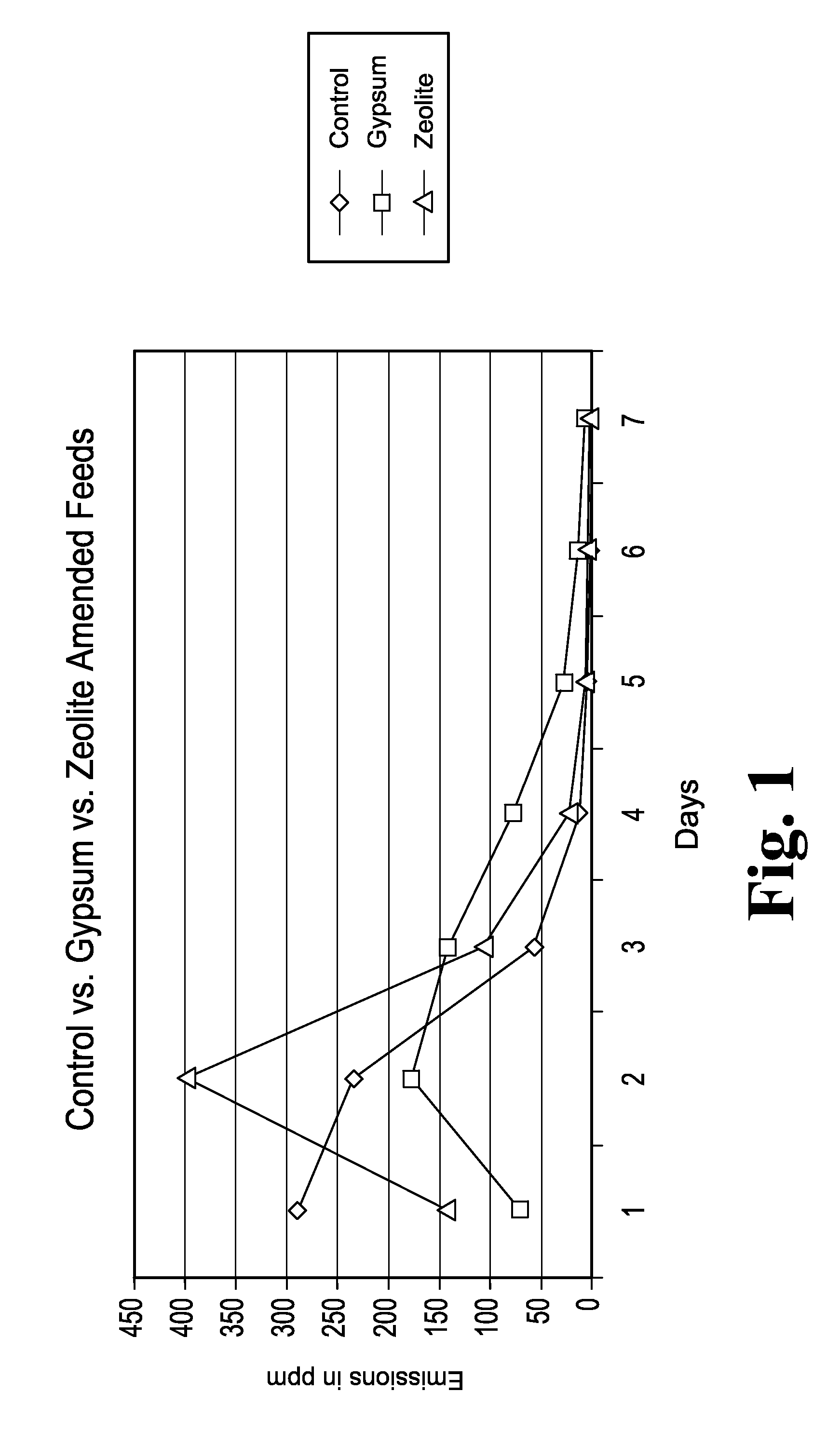

[0089]FIG. 1 illustrates the effect of supplementing chicken feed with zeolite in the absence of added acidogenic substances. Chickens fed rations supplemented with zeolite alone did not produce manure that emitted less ammonia than manure from birds fed...

experiment 3

[0097] Older manure is continually being covered over by fresh as a manure pile accretes. Because ammonia emission occurs from the surface of the manure, accretion may act to suppress ammonia emissions. If this is true, then reducing the amount of ammonia off-gassed from fresh manure even transiently may help to reduce the level of ammonia in a whole hen house.

[0098] In order to test this hypothesis, an entire layer house was fed a ration comprising 1.25% zeolite with 25% of the supplemental calcium derived from gypsum. A second layer house used as a control was fed a control ration with no zeolite and all of its supplemental calcium derived from limestone. Crude protein levels in the two rations were nearly identical: 15.3% and 14.8% of total ration weight, respectively.

[0099] Because birds in the gypsum / zeolite-amended feed house could likely not tolerate an immediate shift from the standard rations to the amended rations, birds fed the amended ration were weaned from their stan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pKa | aaaaa | aaaaa |

| pH | aaaaa | aaaaa |

| pH | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com