Process for preparing a sugar coating on an irregular shaped confection

a technology of irregular shaped confections and sugar coatings, which is applied in confectionery, cocoa, food science and other directions, can solve the problems of ingenuity to overcome, not a simple application of these techniques to coat and inability to achieve the effect of achieving the effect of achieving irregular shaped bite sized confections

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

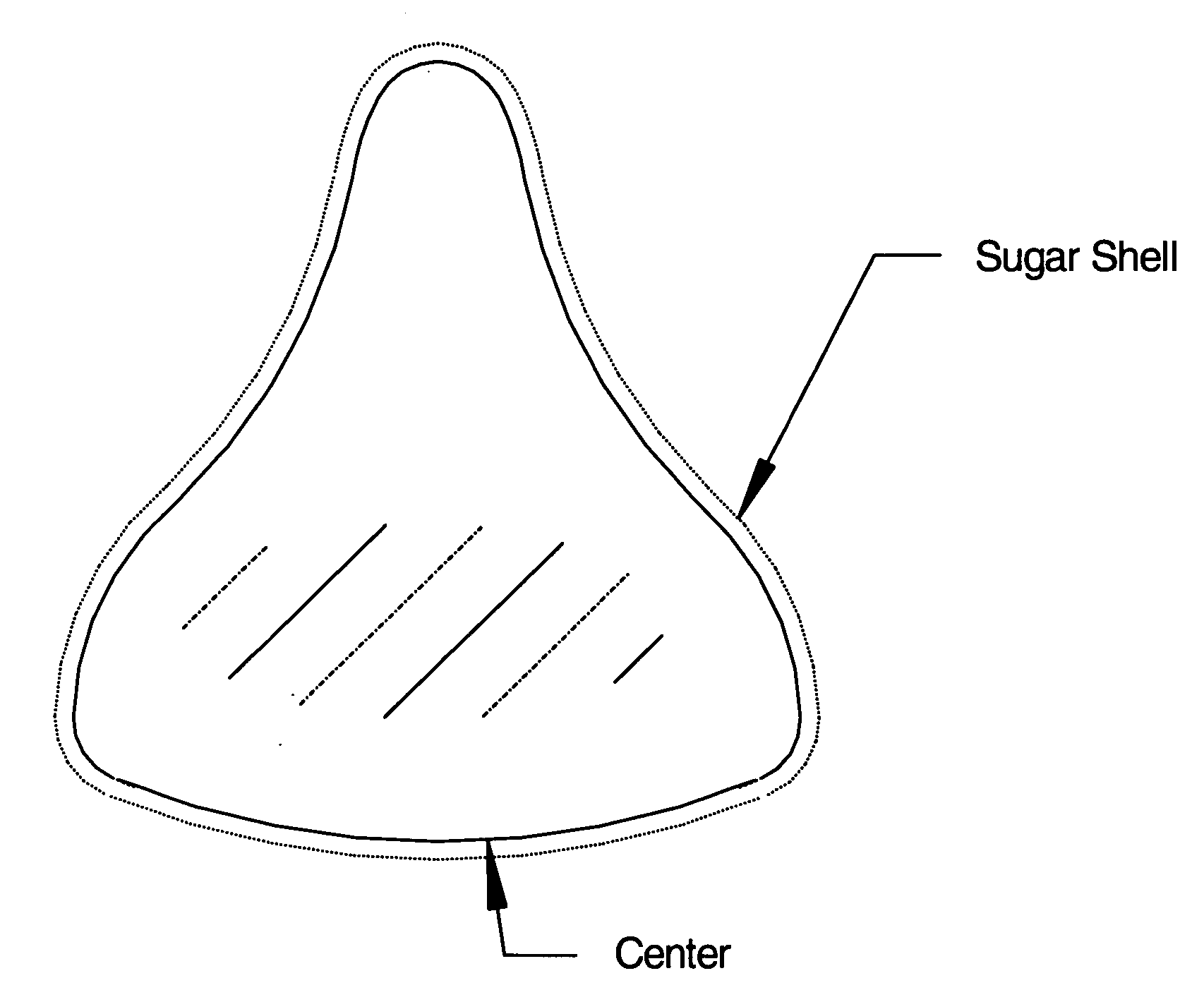

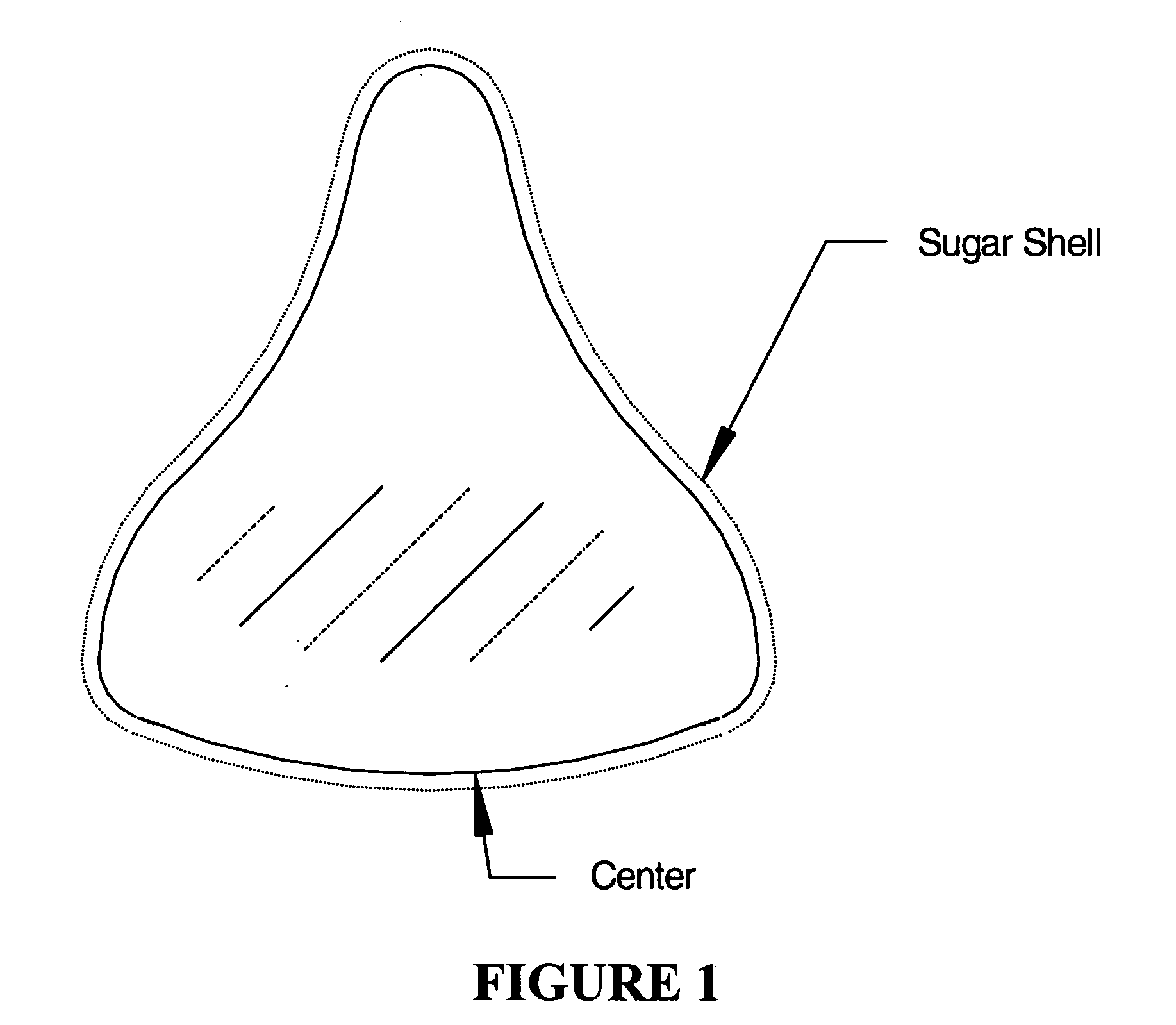

Image

Examples

example 1

[0169]Twenty two pounds of bite-sized heat sensitive Hershey's Kisses® chocolate centers with rounded bottoms were loaded into a 2 foot diameter perforated pan. The centers were cooled to 64 F. Centers were tumbled in the perforated pans at five revolutions per minute or 31.4 feet per minute peripheral speed. A solution of gum arabic syrup, 72% solids solution of sugar, gum arabic and water, were sprayed at a rate of 0.44 pounds per minute on the centers using air atomized spray nozzles. The gum syrup provides protection for the tip, acts as a binding agent and prepares the surface for sugar coating. Dose sizes ranged from 0.48 to 0.57 pounds of syrup. Air atomization was set at 29 psi and remained constant during the entire process. After each application of gum syrup, the product was allowed to spread without air for 40 to 60 seconds. Air was then applied and the product was dried with 80.6-82.4 F air at a dew point of 36 F for about six to seven minutes. The air volume was direct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com