Membranes with controlled permeability to polar and apolar molecules in solution and methods of making same

a technology of polar molecules and membranes, applied in the field of biocompatible synthetic membranes, can solve the problems of fundamental difficulty in preparing interpenetrating networks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

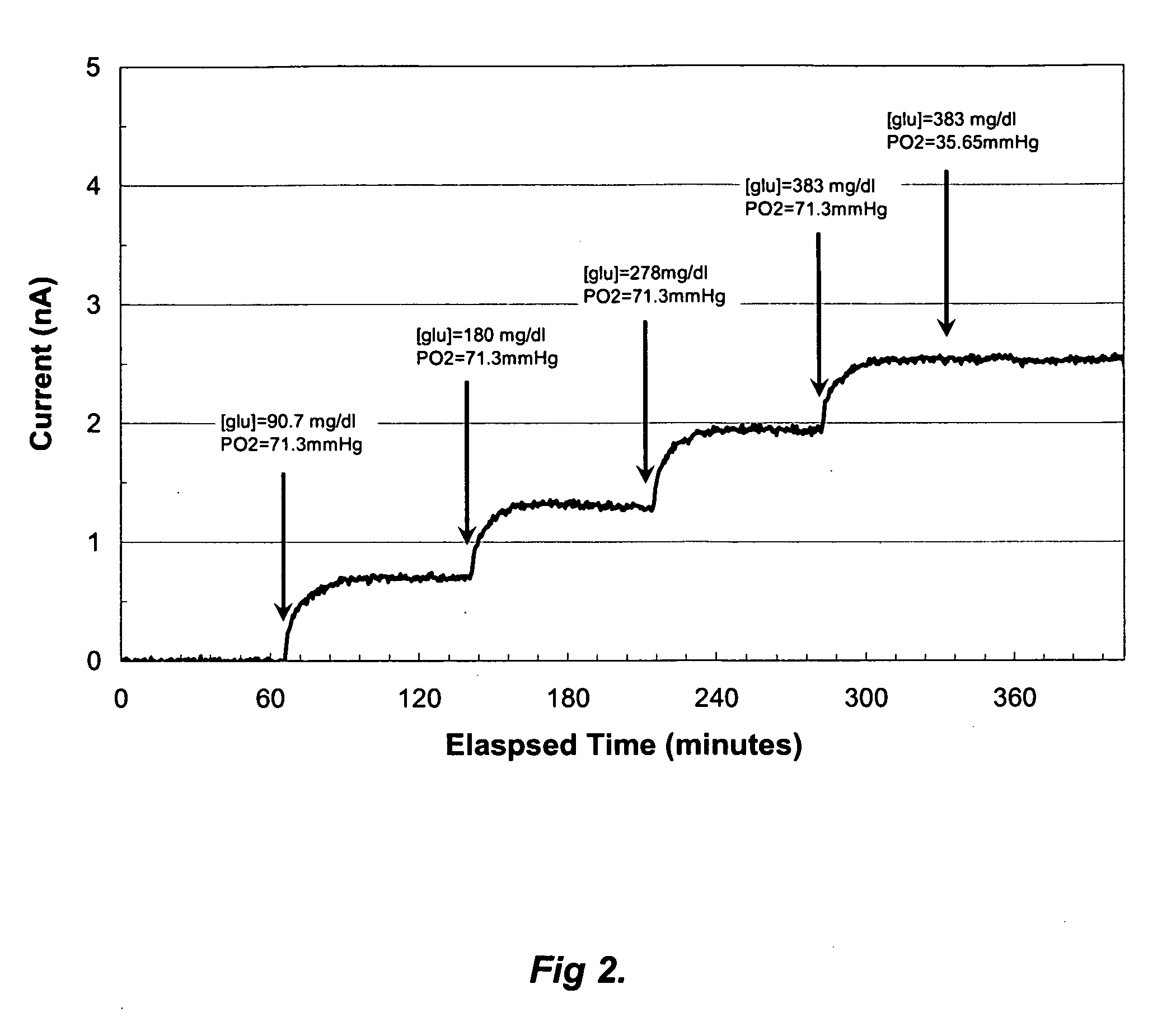

Hydrogen Peroxide-Based Glucose Sensor Constructed with Membrane Operated In Vitro

[0138]In addition to being useful in oxygen-based enzyme electrode sensors, the membranes of the invention may also find application in hydrogen peroxide-based enzyme electrode sensors, so-called “wired enzyme” sensors, or other implantable sensors. As a demonstration of usefulness in a hydrogen peroxide-based enzyme electrode sensor for glucose, a sensor plate was again constructed using a Type 2 membrane of the invention. The plate construction method was as described above in “Methods for Production of Type 2 Membranes.” However, for this demonstration, instead of being poised at a cathodic potential for oxygen reduction, the single working electrode of the sensor plate was poised instead at an anodic potential suited for hydrogen peroxide oxidation, and the PDMS layer overlying the working electrode was removed, to allow diffusion of hydrogen peroxide from the immobilized enzyme layer to the workin...

example 2

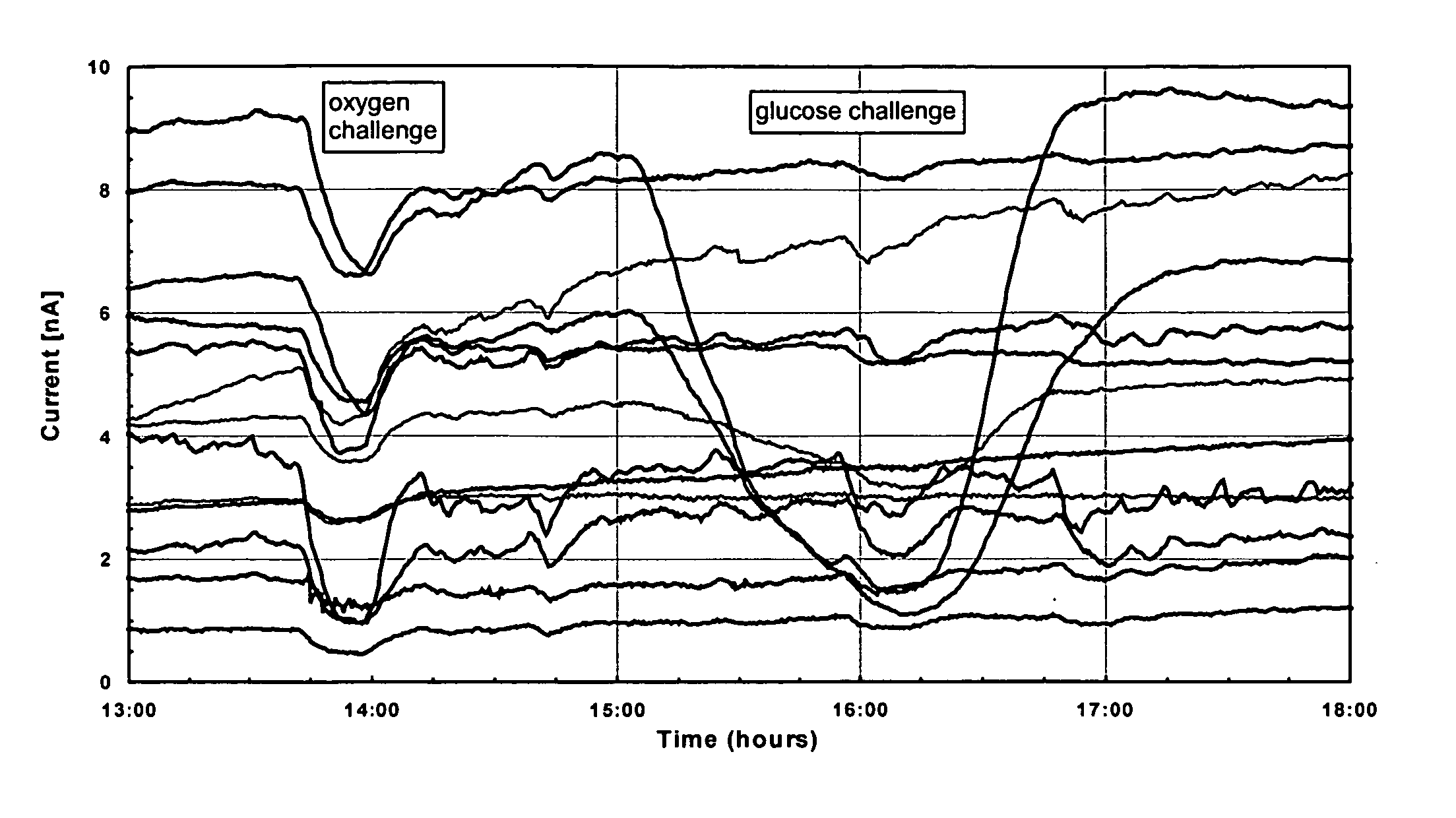

Hydrogen Peroxide-Based Glucose Sensors Constructed with Membranes Operated In Vitro at Low Oxygen Concentration

[0140]As a further demonstration of usefulness in hydrogen peroxide-based enzyme electrode sensors for glucose, sensor plates were constructed using both Type 1 and Type 2 membranes of the invention. The plate construction method was as described in Example 1, with the addition of a layer of cellulose acetate between the enzyme layer and the underlying electrolyte gel layer, as is understood by those skilled in the art to be useful for reducing the influence of interfering substances. As in Example 1, the working electrodes of the sensor plates were poised at an anodic potential suited for hydrogen peroxide oxidation. The sensor plates were inserted into a port in a thermostatted reaction vessel containing PBS, maintained at 37° C. such that the sensor was immersed in the solution, and the extended sensor plate was connected electrically to the potentiostat instrumentation...

example 3

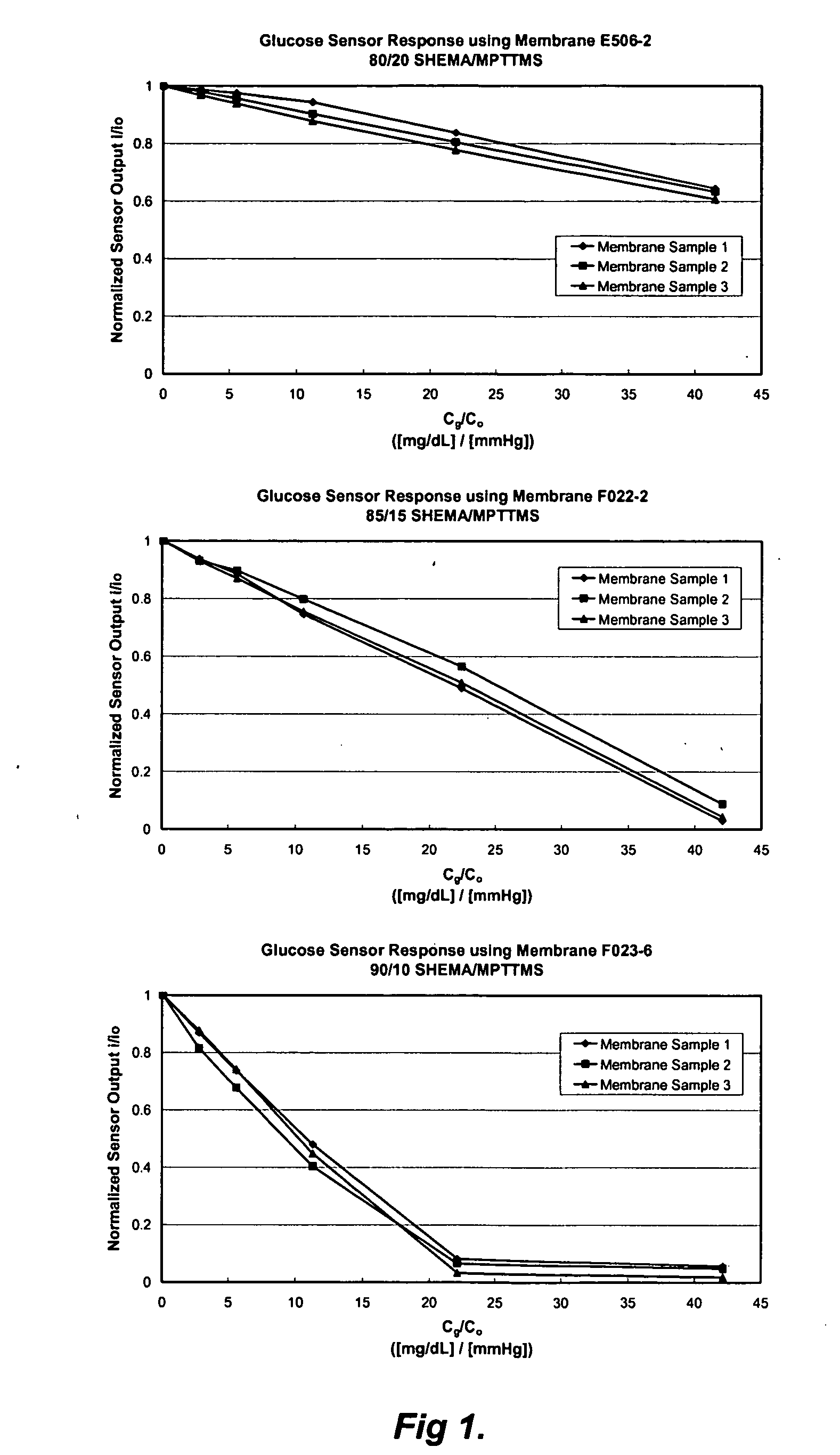

Oxygen-Based Glucose Sensor Constructed with Membrane Operated as an Implant in a Hamster

[0142]This example describes the operation of sensors incorporating a Type 2 membrane and a sensor body as a glucose sensor implant in an experimental hamster preparation.

[0143]Male Golden Syrian hamsters obtained from Charles River Laboratories, Cambridge, Mass., weighing between 60 and 200 g were housed in standard micro-isolator cages ventilated with HEPA filtered air and were fed Purina Hamster Chow and water ad libitum. Animals were treated in accordance with NIH guidelines for the care and use of laboratory animals. The window chamber support apparatus, described in detail elsewhere (Milan T. Makale, Joe T. Lin, Richard E. Calou, Amy G. Tsai, Peter C. Chen, and David A. Gough, “Tissue window chamber system for validation of implanted oxygen sensors,” Am J Physiol Heart Circ Physiol, June 2003; 284: 2288-2294, incorporated herein by this reference), consisted of two titanium alloy frames, e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Percent by mass | aaaaa | aaaaa |

| Percent by mass | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com