Hybrid vehicle and hybrid power system

a hybrid power system and hybrid technology, applied in the direction of mechanical equipment, electric propulsion mounting, transportation and packaging, etc., can solve the problems of inability to achieve the required power effect, limited power efficiency of these new power sources, and inability to use a single power source, so as to improve the power transmission efficiency of the automatic manual transmission system, speed change is smooth, and the effect of reducing the abrasion of the gear shifting devi

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

The First Embodiment

[Hybrid Vehicle]

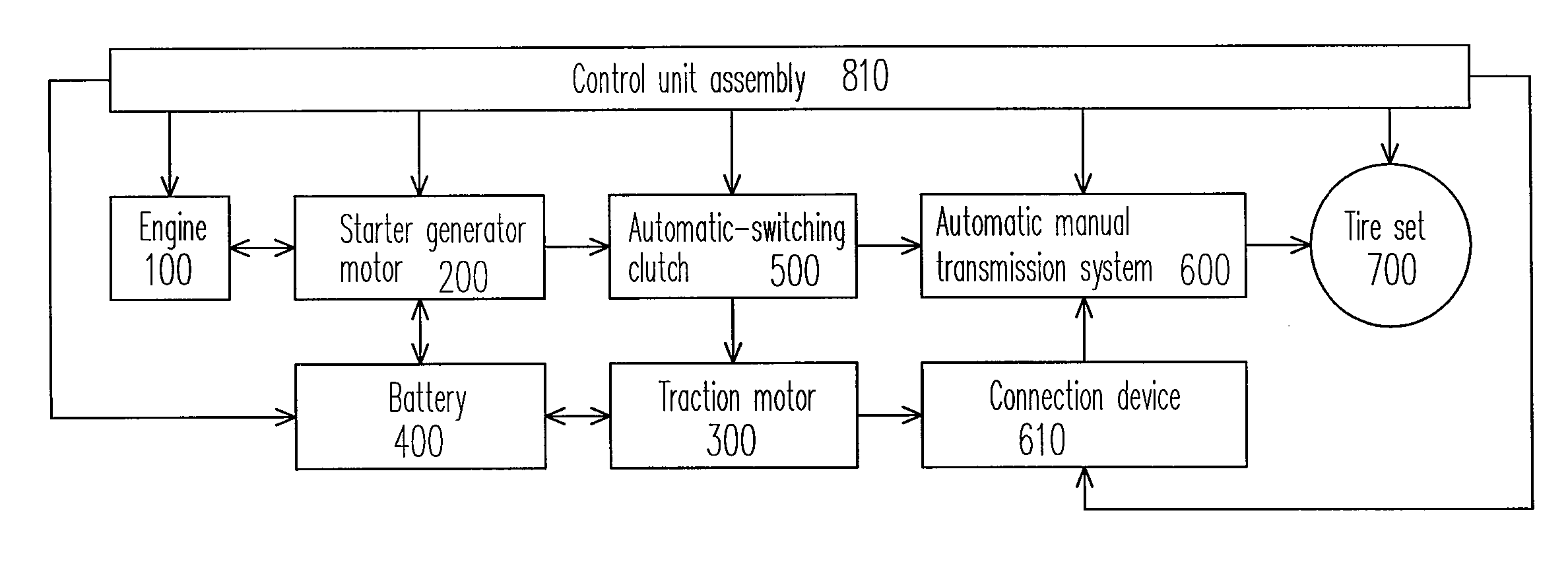

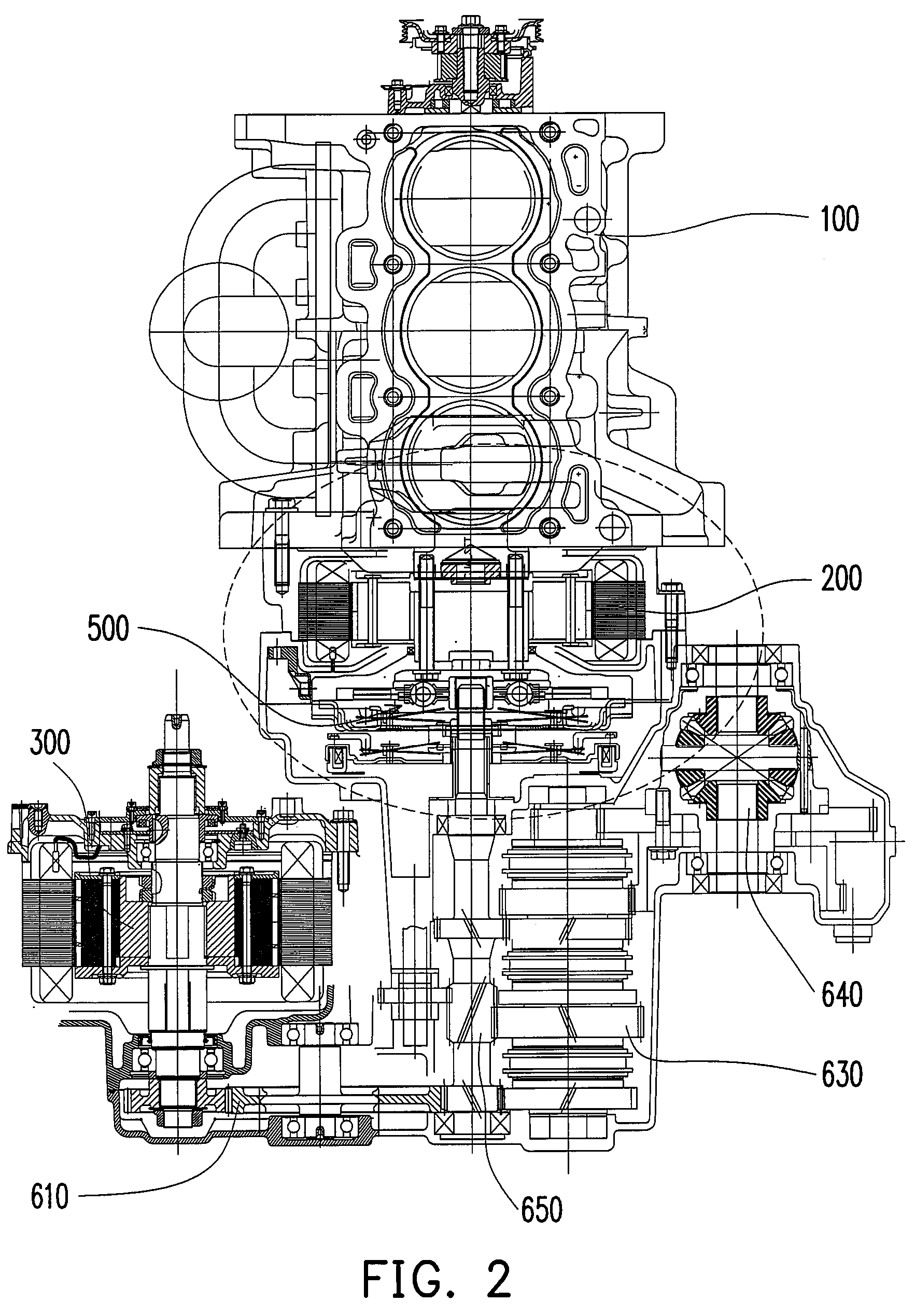

[0042]FIG. 1 is a block diagram of a hybrid vehicle according to a first embodiment of the present invention.

[0043]The hybrid vehicle using at least two energies of the present invention includes an engine 100 serving as a first power, a starter generator motor 200, a traction motor 300 serving as a second power, a battery 400, an automatic-switching clutch 500, an automatic manual transmission system 600, a connection device 610, a tire set 700 and a transmission shaft (not shown), and a control unit assembly (a power-type-controlling unit) 810.

[0044]The starter generator motor 200 is coupled with the engine 100, and synchronously rotates with the engine 100 for starting the engine 100 and serving as an assistant power.

[0045]The automatic manual transmission system 600 is coupled with the traction motor 300 through a connection device 610. Herein, the connection device, for example, includes a gear set, a sprocket and chain set, a belt and pulley...

example 1

[Mechanical Arrangement Example 1]

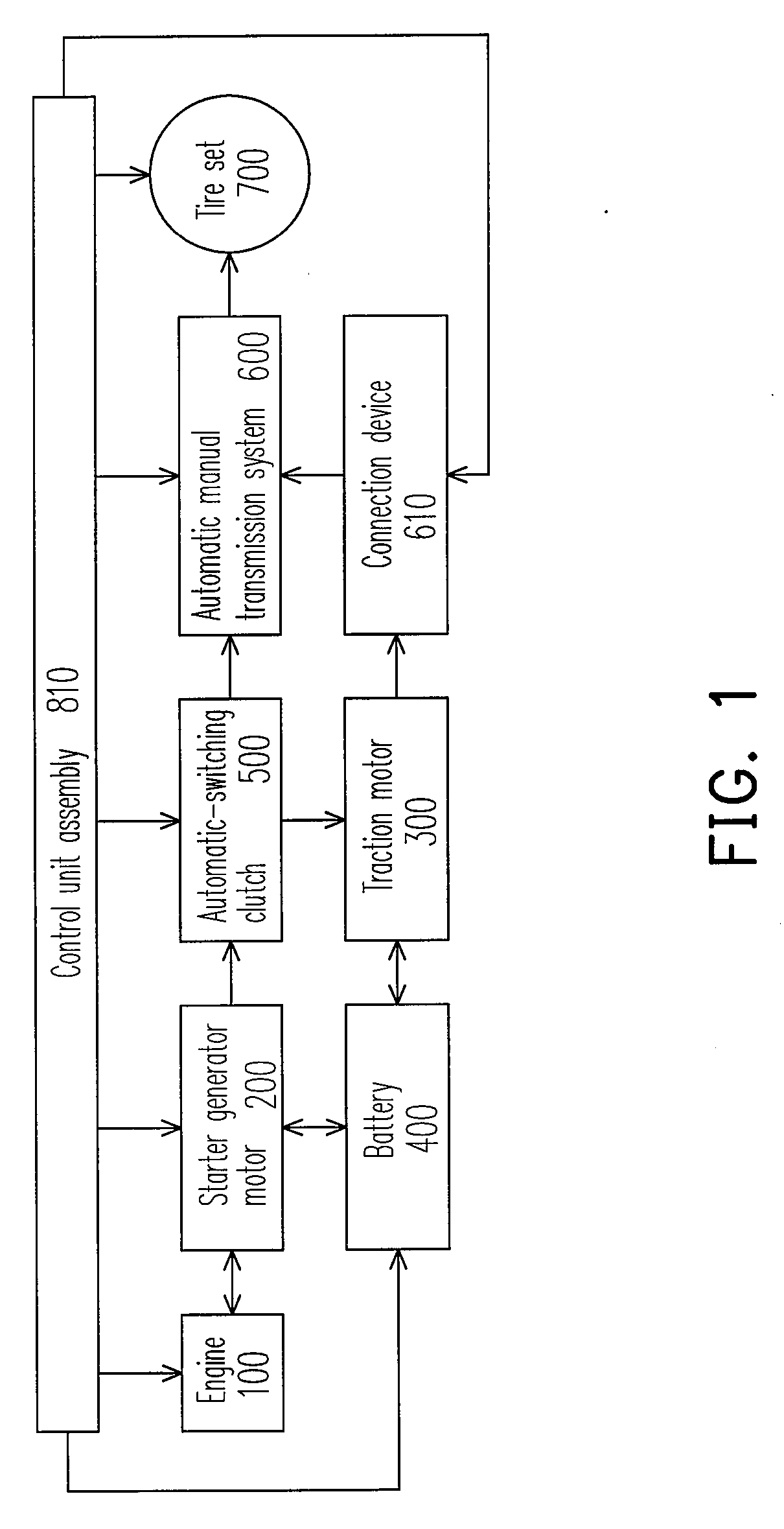

[0050]Referring to FIGS. 2 and 3, FIG. 2 is a schematic view of a mechanical arrangement of the above components according to Example 1, and FIG. 3 is a partial enlarged view of the dashed area of FIG. 2.

[0051]The starter generator motor 200 and the automatic-switching clutch 500 (for example, an electromagnetic disc clutch) are arranged on the same side of the engine 100. The starter generator motor 200 adopts an inner rotor design. A clutch flywheel 542 is directly locked onto a flange coupling 102f on the left end of the engine crank 102 by using a screw 524b passing through a rotor 202.

[0052]The automatic manual transmission system 600 is connected to a transmission main shaft 650 through a differential 640 and then connected to the tire set 700 (FIG. 1).

example 2

[Mechanical Arrangement Example 2]

[0053]Referring to FIGS. 4 and 5, FIG. 4 is a schematic view of a mechanical arrangement of the above components according to Example 2, and FIG. 5 is a partial enlarged view of the dashed area of FIG. 4.

[0054]The starter generator motor 200 and the automatic-switching clutch 500 (for example, an electromagnetic disc clutch) are arranged on two sides of the engine 100. The starter generator motor 200 adopts an outer rotor design. The rotor 202 is directly locked onto a tapered shaft 102t on the right end of the engine crank 102. A clutch flywheel 542 is directly locked onto a flange coupling 102f on the left end of the engine crank 102.

[0055]The automatic manual transmission system 600 is connected to a transmission main shaft 650 through a differential 640 and then connected to the tire set 700 (FIG. 1).

[0056]In the above two mechanical arrangement examples, the disengagement or engagement of the clutch flywheel 542 and the clutch set 540 involves ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com