Finish guard

a technology of finishing guard and sleeve, which is applied in the field of mechanical sleeves, can solve the problems of further cost savings in both labor and mat, and achieve the effects of preventing discoloration and deterioration, reducing labor costs, and reducing labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

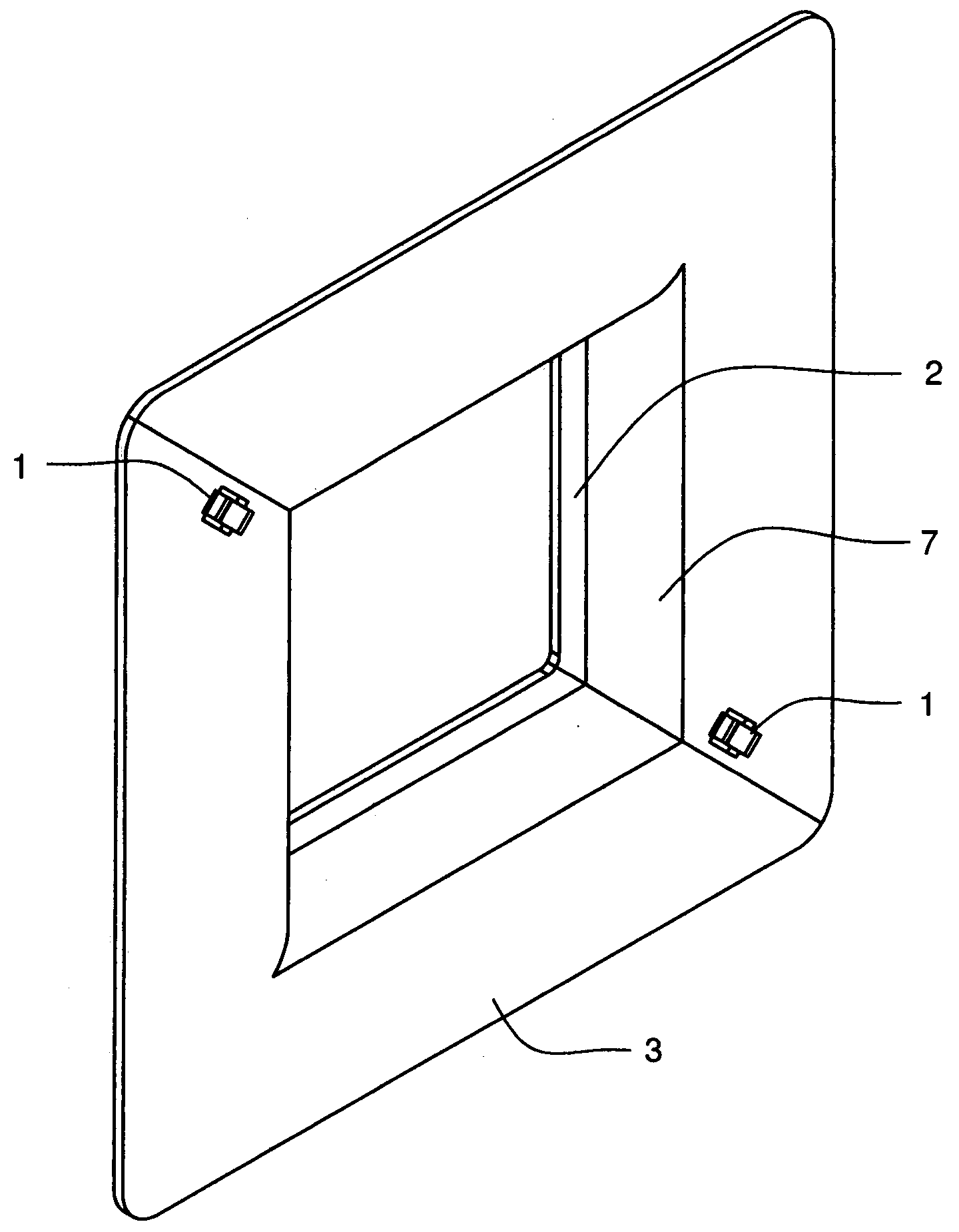

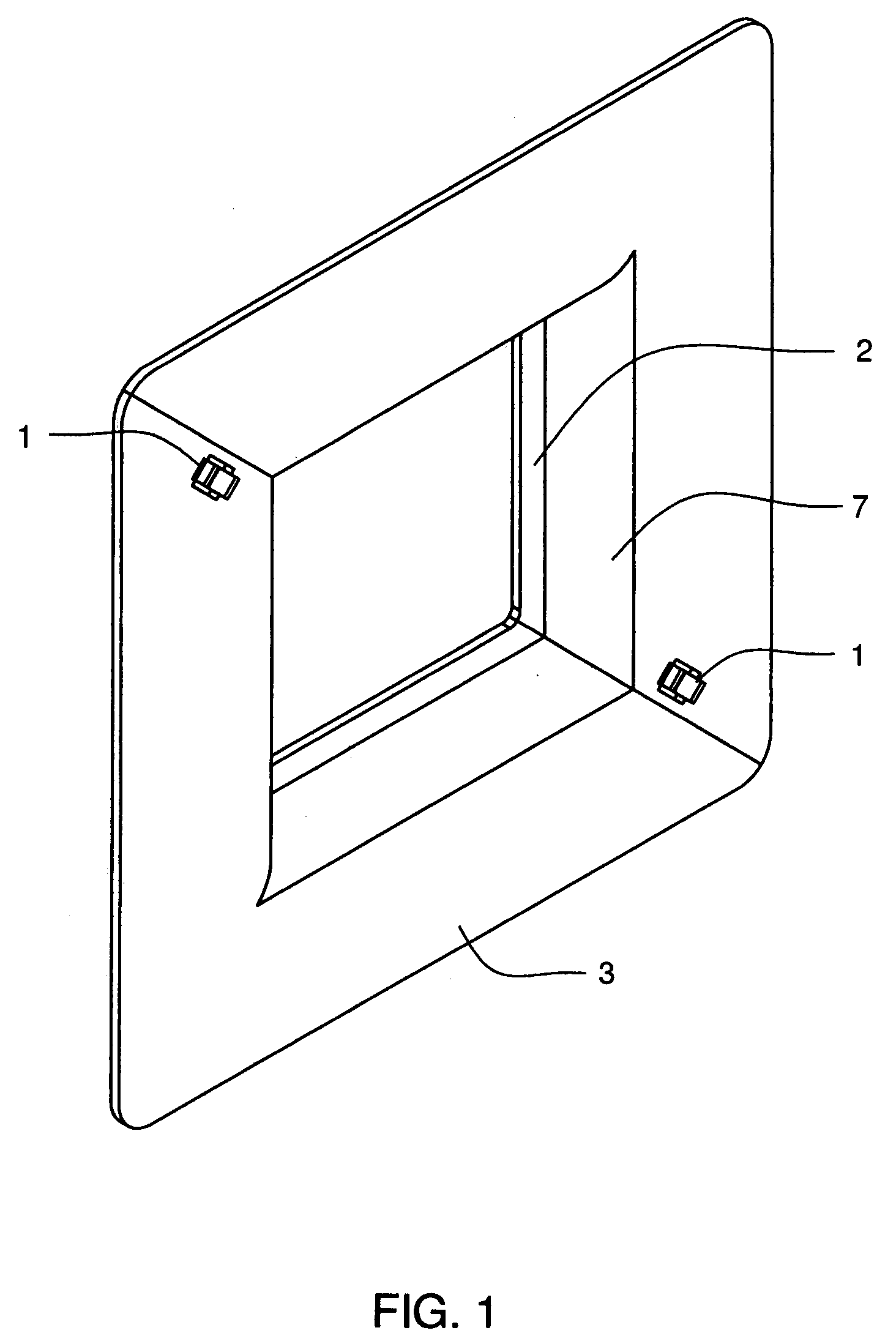

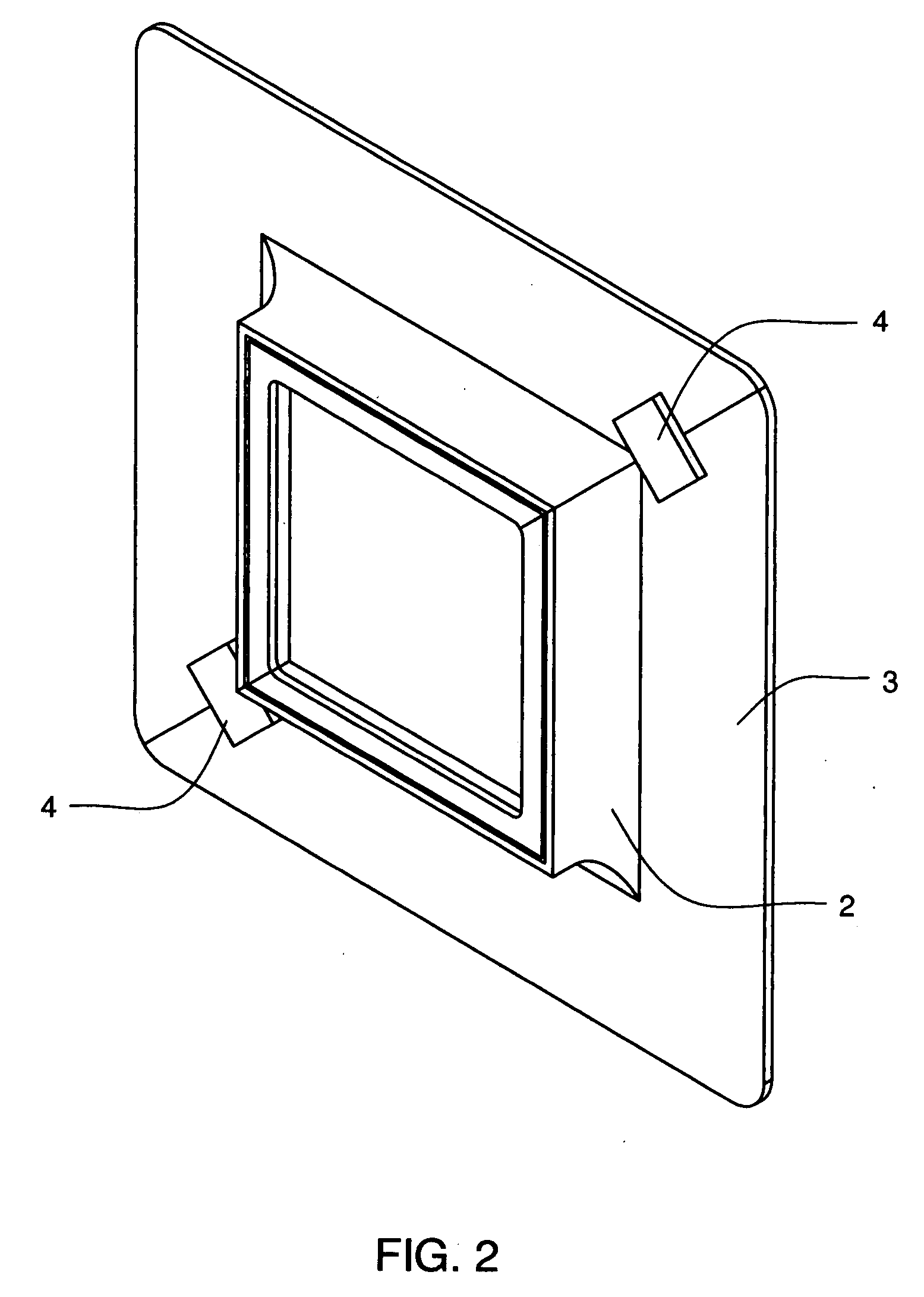

Image

Examples

Embodiment Construction

[0015]In the preferred embodiment, the trim guard of the instant invention is constructed of polyvinylchloride. However, any polymeric material with the necessary impact strength is suitable, for instance polyethylene, polybutylene, or polypropylene. Copolymers are also suitable, such as ABS copolymer. It must be remembered the trim guard is intended for outdoor use. Therefore, the material selected must possess the requisite thermal properties, i.e. it must not become overly brittle at cold winter temperatures and at the same time it must not become unnecessarily soft at higher summer temperatures. Polyvinylchloride plasticized with dioctylthalate or doctyladipate, and epoxidized soy bean oil, is commonly used in these temperature extremes. The material must also be resistant to radiant degradation, normally encountered when polymeric materials are exposed to sunlight. Any material selected absolutely must be impact resistant to mechanical abrasion, as when a string rotary trimmer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com