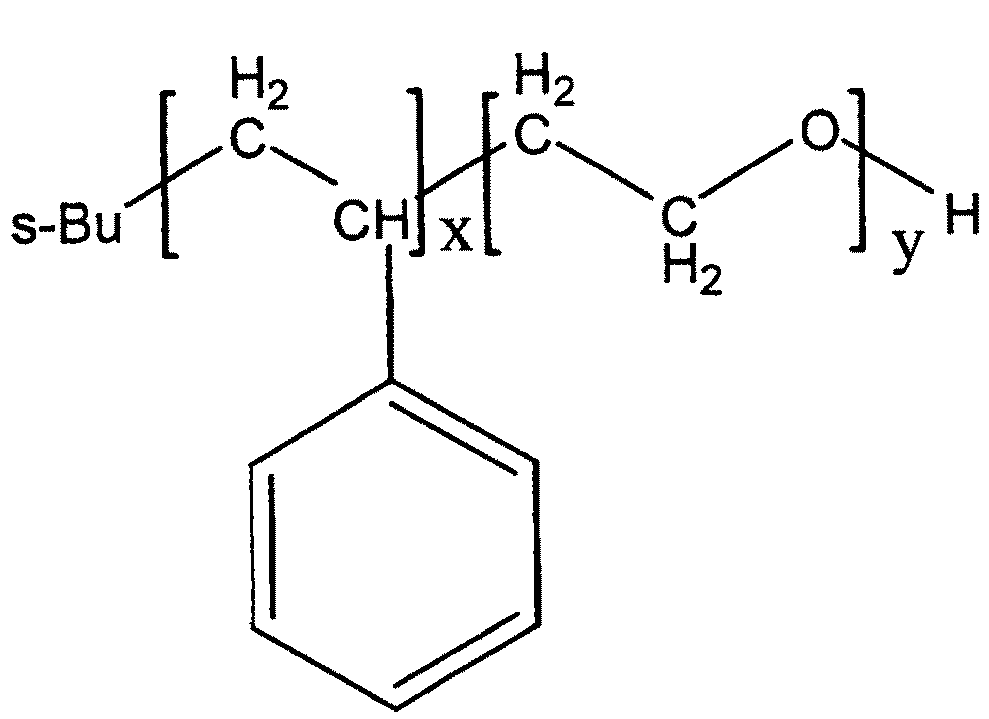

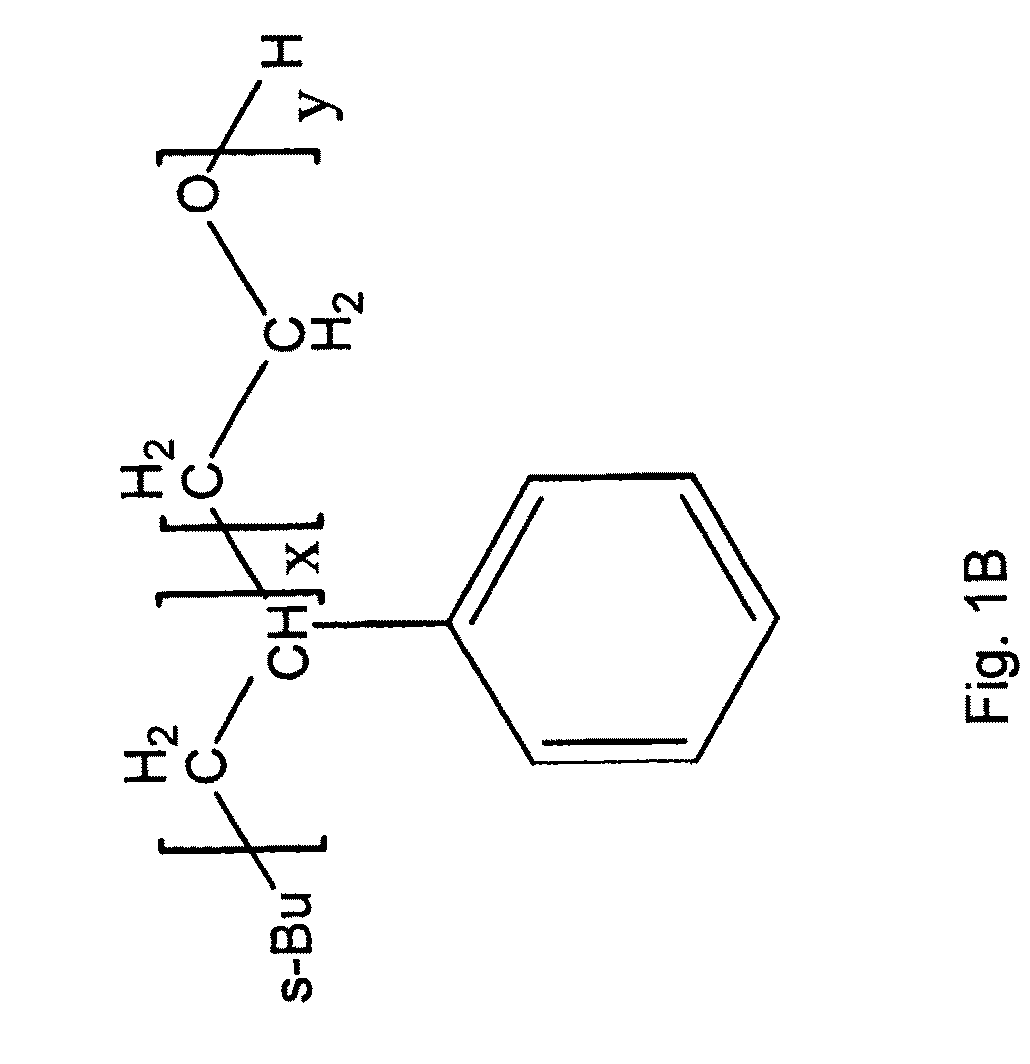

High elastic modulus polymer electrolytes suitable for preventing thermal runaway in lithium batteries

a polymer electrolyte and high elastic modulus technology, applied in the field of polymer electrolyte, to achieve the effect of preventing thermal runaway and dropping conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples

[0092]The following examples provide details relating to composition, fabrication and performance characteristics of block copolymer electrolytes in accordance with the present invention. It should be understood the following is representative only, and that the invention is not limited by the detail set forth in these examples.

[0093]To characterize the electrolyte, experimental data results were obtained by methods such as transmission electron microscopy (TEM), small angle X-ray scattering (SAXS), AC impedance spectroscopy, and rheology. AC impedance spectroscopy measurements were made using a test cell on thermo-stated pressed samples in the glove box, and a Solartron 1260 Frequency Response Analyzer machine connected to a Solartron 1296 Dielectric Interface. The polymer samples for TEM and SAXS were annealed using the same thermal history as that used for conductivity measurements. The electrolyte samples were kept at 120° C. for 2 hrs, and cooled to room temperature. Thin secti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com