Stretchable conductor sheet and paste for forming stretchable conductor sheet

a technology of stretchable conductors and conductor sheets, which is applied in the direction of pigmenting treatment, non-conductive materials with dispersed conductive materials, synthetic resin layered products, etc., can solve the problems of unsuitable mass production methods, unsuitable for mass production, and the inability to resist heat and heat, so as to reduce the anisotropy of conductivity, hinder conductivity, and reduce the deformation in different directions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples

[0157]Hereinafter, the invention will be explained in more detail and specifically by further showing examples. Evaluation results etc. of examples were measured by the following method.

[0158]The amount of nitrile was converted from the composition ratio obtained by analyzing the resulting flexible resin material by NMR to a ratio by mass (% by mass) of monomer.

[0159]The measurement was conducted using SMV-300RT “Mooney Viscometer” manufactured by Shimadzu Corporation.

Amount of Alkali Metal>

[0160]The resin was subjected to an ashing treatment, the resulting ash was extracted by means of hydrochloric acid, the contents of sodium and potassium were determined by atomic absorption spectrometry, and both contents were summed.

[0161]The flexible resin was heated, compressed and molded into a sheet having a thickness of 200±20 μm, and then punched out into a dumbbell shape defined by ISO 527-2-1A to obtain a test piece. A tensile test was performed by the method defined in ISO 527-1 to det...

production example

[0176]Butadiene 54 parts by mass, acrylonitrile 46 parts by mass, deionized water 270 parts by mass, sodium dodecylbenzenesulfonate 0.5 part by mass, sodium naphthalenesulfonate condensate 2.5 parts by mass, t-dodecyl mercaptan 0.3 part by mass, triethanolamine 0.2 part by mass, and sodium carbonate 0.1 part by mass were put into a stainless steel reactor equipped with a stirrer and a water cooling jacket and gently stirred while keeping the bath temperature at 15° C. by flowing nitrogen. Next, an aqueous solution prepared by dissolving 0.3 part by mass of potassium persulfate in 19.7 parts by mass of deionized water was added dropwise into the reactor over 30 minutes, reaction was further continued for 20 hours, an aqueous solution prepared by dissolving 0.5 part by mass of hydroquinone in 19.5 parts by mass of deionized water was then added thereto, and an operation for stopping the polymerization reaction was carried out. The polymerization temperature was 15° C.

[0177]Next, in or...

experiment 1

(Experiment 1)

[Paste Forming Stretchable Conductor Sheet]

[0191]As shown in Table 4-1, the components were blended, and then kneaded by a three-roll mill to prepare pastes for forming a stretchable conductor sheet in Examples 11 to 17 and Comparative Examples 11 to 13.

[Stretchable Conductor Sheet]

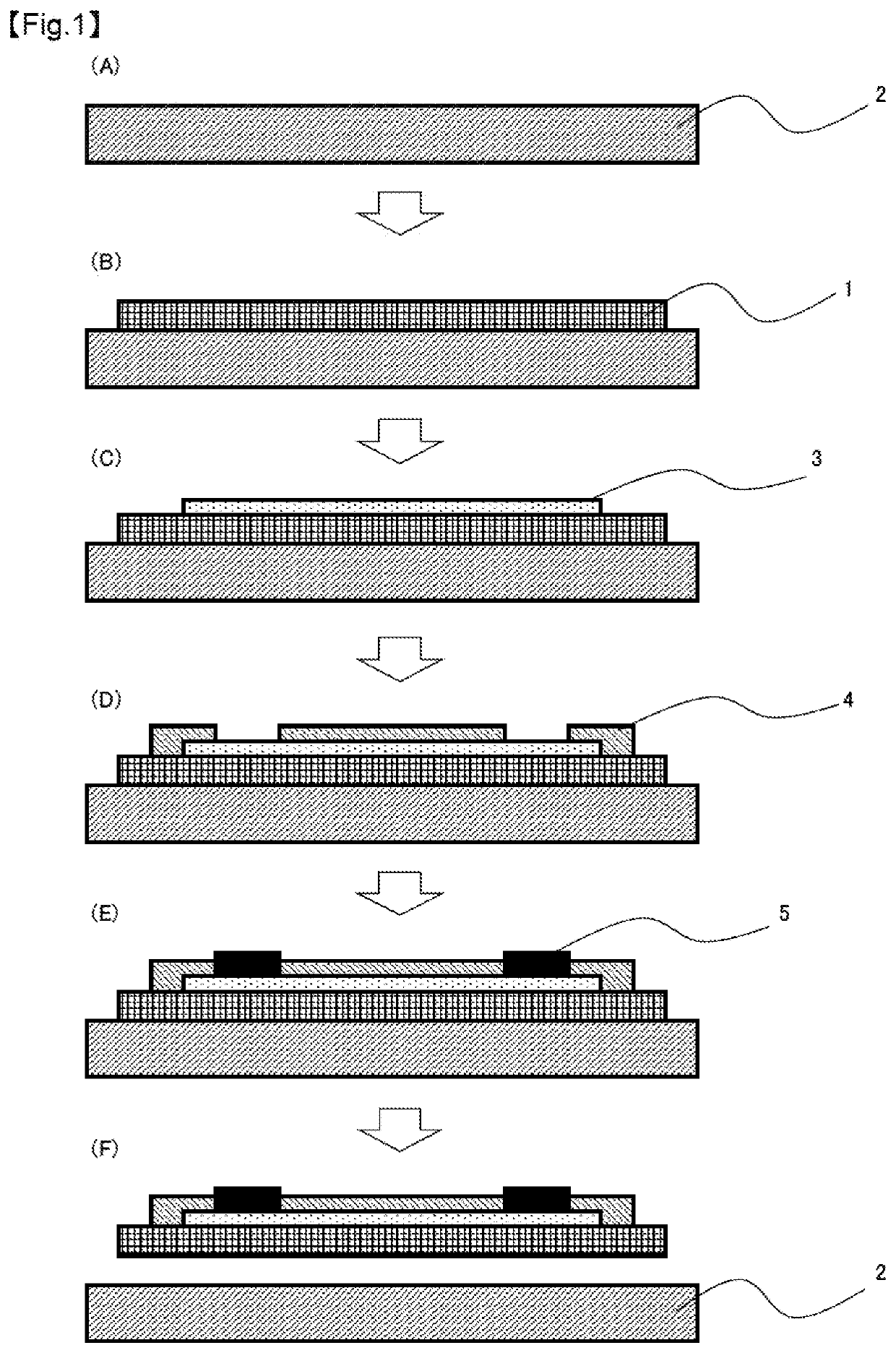

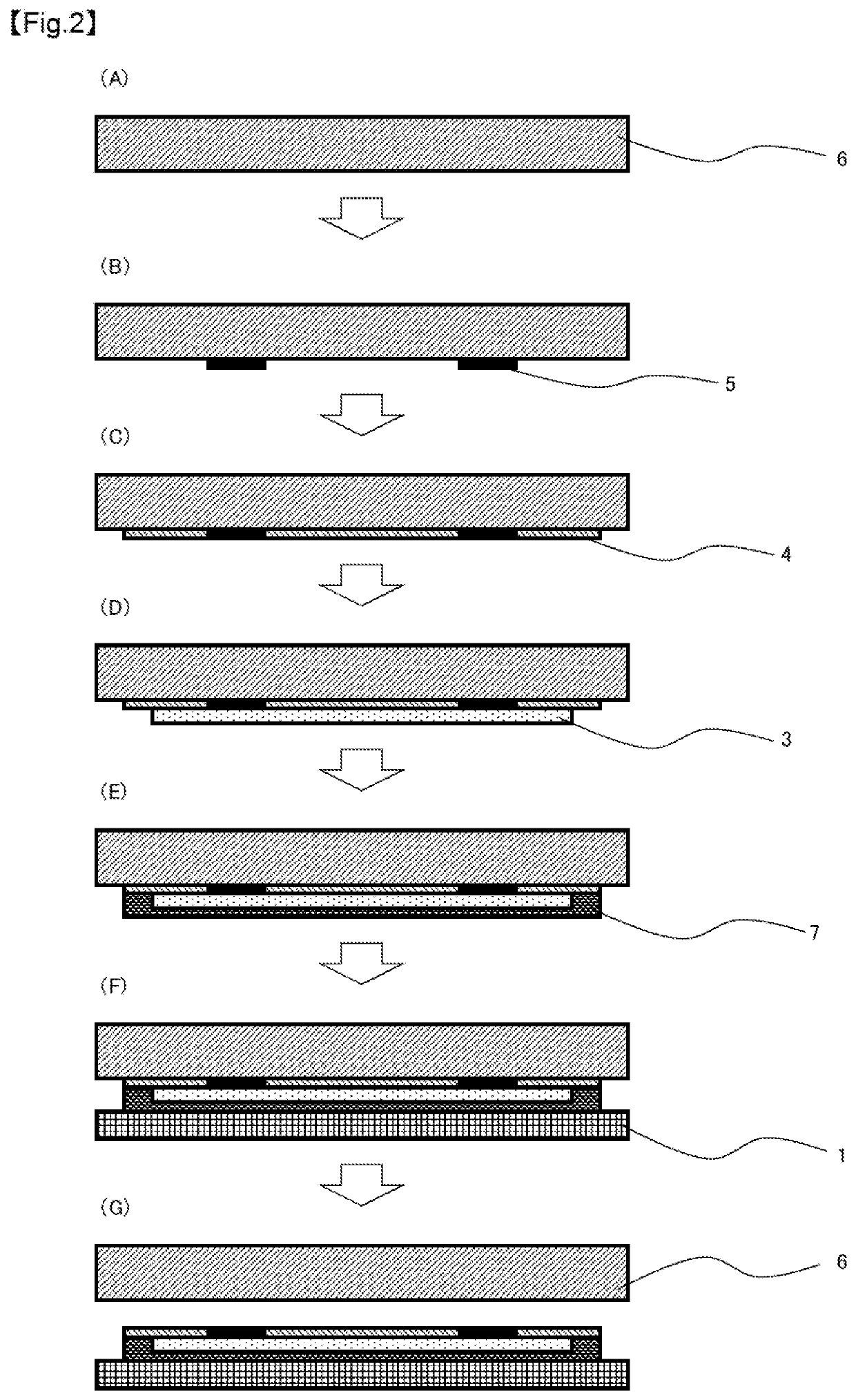

[0192]A paste for forming a stretchable conductor sheet in each of Examples 11 to 17 and Comparative Examples 11 to 13 as shown in Table 4-1 was applied onto a Teflon (registered trademark) sheet by an applicator to form a film (application direction(A)), and drying was performed at 120° C. for 20 minutes to form a stretchable conductor sheet having a thickness of 50 μm. For the obtained stretchable conductor sheet, the specific resistance in a natural state (elongation ratio: 0%) was measured by the above-described method. In addition, the specific resistances at the time of elongation by 40% in the application direction (A) and the specific resistance at the time of elongation by 40% in th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile elastic modulus | aaaaa | aaaaa |

| tensile elastic modulus | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com