Novel Skin Lightening Agents, Compositions and Methods

a skin lightening agent and composition technology, applied in the field of substituted resorcinol derivative compounds, can solve the problems of compound low efficacy or undesirable side effects, etc., and achieve the effect of less irritation to the skin, cost-effective preparation of commercially available substances, and effective skin lightening properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

Procedure for Making 1,3-dithiane Resorcinol

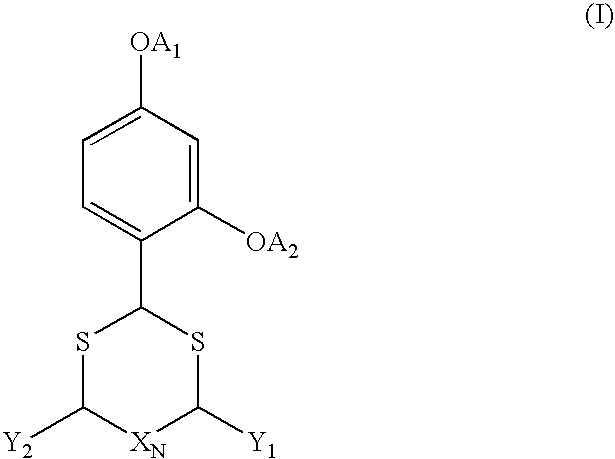

[0068]The compound of formula III was prepared in accordance with the process discussed hereinbelow and used throughout the examples that follow:

[0069]In a most preferred embodiment designated by the compound of formula II, N is zero; each A1 and A2 represents H, both Y1 and Y2 represent H, because it is most cost-effective to manufacture. This most preferred embodiment, referred to herein as 1,3-dithiane resorcinol, may be prepared by reaction of 2,4-dihydroxy benzaldehyde and 1,3-Dimercaptoethane (Both starting materials are available from Yick-Vic Chemicals & Pharmaceuticals (HK) Ltd / Hong Kong), denoted by the following formula III and catalyzed by an acid catalyst. Suitable catalysts include but are not limited to methane sulfonic acid, p-toluene sulfonic acid, H2SO4 (sulfuric acid), HCl (hydrochloric acid) and acidic resins.

[0070]A three necked flask equipped with a Dean-Stark apparatus, an additional funnel and a condenser is charged...

example 2

Cosmetic Compositions within the Scope of the Invention were Prepared

[0071]A base formulation shown in Table 3, below, was made by heating phase

[0072]A ingredients to 70 to 85° C. with stirring. Phase B ingredients were heated in a separate container to 70 to 85° C. with stirring. Then, phase A was added into phase B while both phases were kept at 70 to 85° C. The mixture was stirred for at least 15 minutes at 70 to 85° C., then cooled.

[0073]A base formulation is shown in the table below.

TABLE 5abIngredients% wt.% wt.PhaseIsostearyl Palmitate6.006.00AC12-C15 Alkyl Octanoate3.003.00APEG-100 Stearate2.002.00AGlyceryl Hydroxystearate1.501.50AStearyl Alcohol1.501.50AStearic acid3.004.00ATEA, 99%1.201.20BDimethicone1.001.00ASorbitan Monostearate1.001.00AMagnesium Aluminum Silicate0.600.60BVitamin E acetate0.100.10ACholesterol0.500.50ASimethicone0.010.01BXanthan gum0.200.20BHydroxyethylcellulose0.500.50BPropylparaben0.100.10BDisodium EDTA0.050.05BButylated hydroxytolene0.050.05BCompound o...

example 3

[0074]Additional cosmetic compositions within the scope of the invention were prepared.

TABLE 6Wt %Phasewater, DIBALANCEAdisodium EDTA0.05Amagnesium aluminum silicate0.6Amethyl paraben0.15Asimethicone0.01Abutylene glycol 1,33.0Ahydroxyethylcellulose0.5Aglycerine, USP2.0Axanthan gum0.2Atriethanolamine1.2Bstearic acid3.0Bpropyl paraben NF0.1Bglyceryl hydroxystearate1.5Bstearyl alcohol1.5Bisostearyl palmitate6.0BC12-15 alcohols octanoate3.0Bdimethicone1.0Bcholesterol NF0.5Bsorbitan stearate1.0BMicronized titanium dioxide5.0Ctocopheryl acetate0.1BPEG-100 stearate2.0Bsodium stearoyl lactylate0.5Bhydroxycaprylic acid0.1CCompound of Formula III10.0CPARSOL MCX2.4Calpha-bisabolol0.2C

The composition of Example 3, was prepared as follows:

[0075]1. Heat Phase A to 80° C.

[0076]2. Heat Phase B to 75° C. in a separate container

[0077]3. Add B to A and mix with heat off for 30 min.

[0078]4. At 50° C. add Phase C and mix for 10 min.

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com