Duplex-Chamber Package

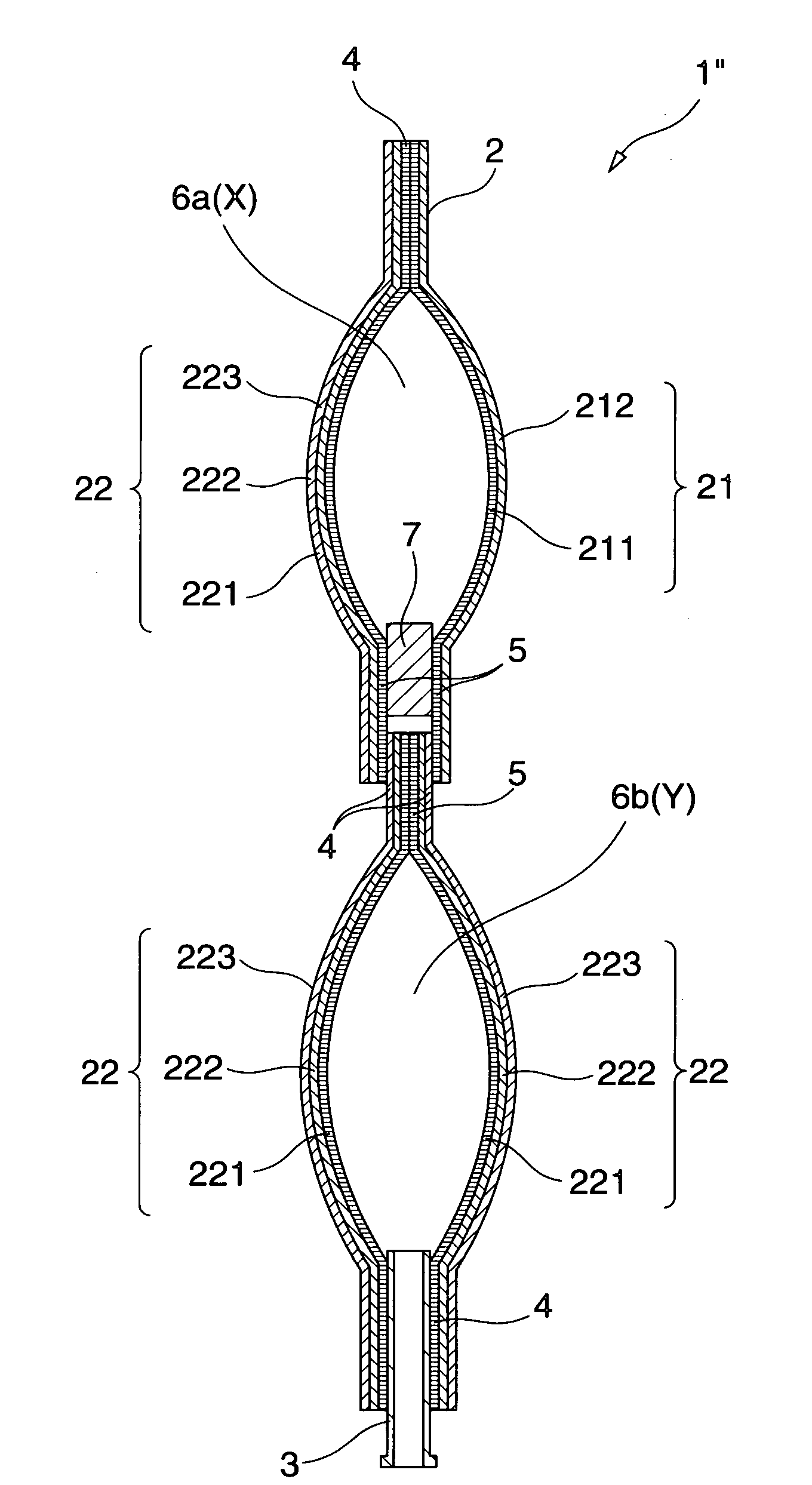

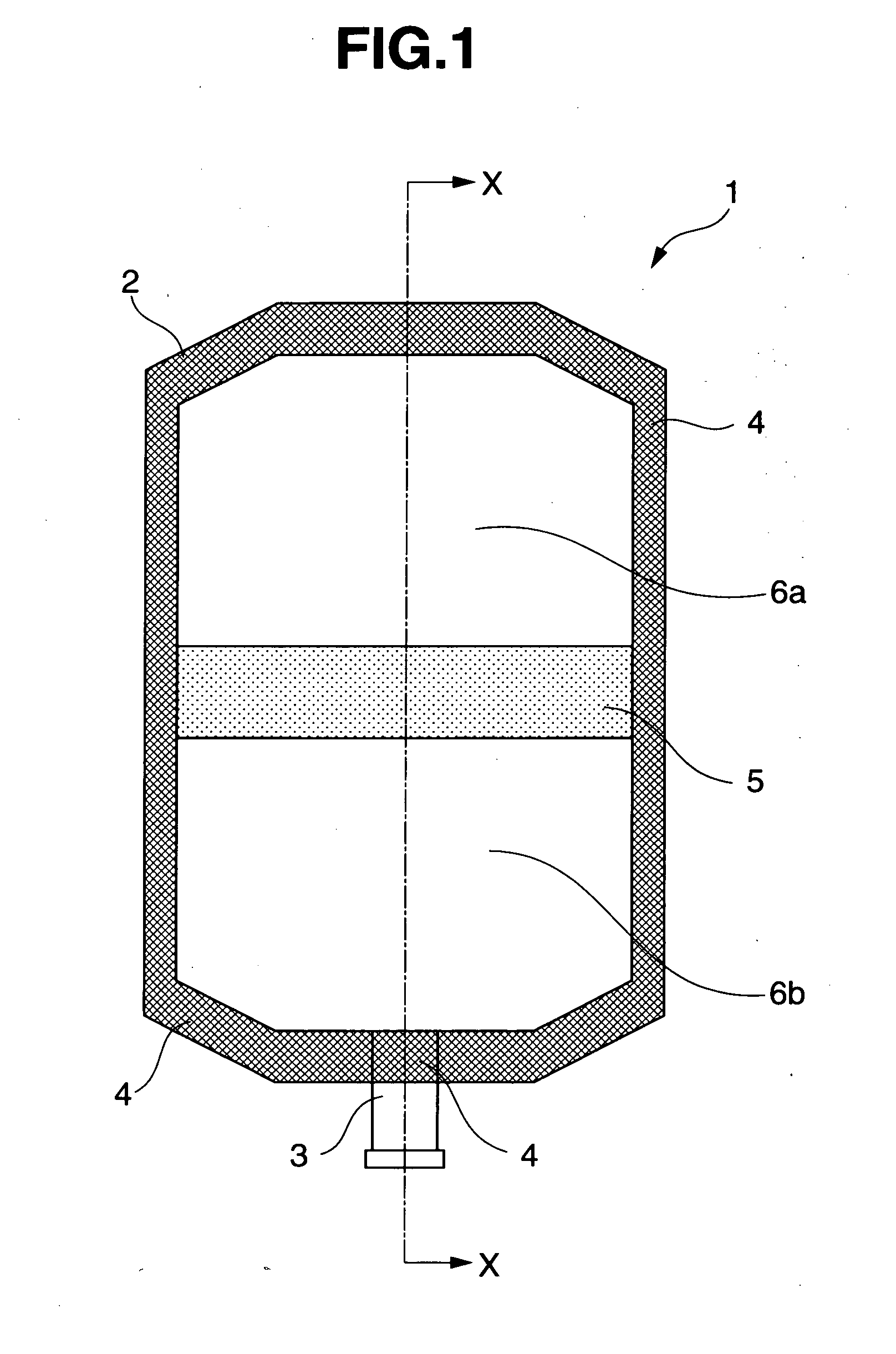

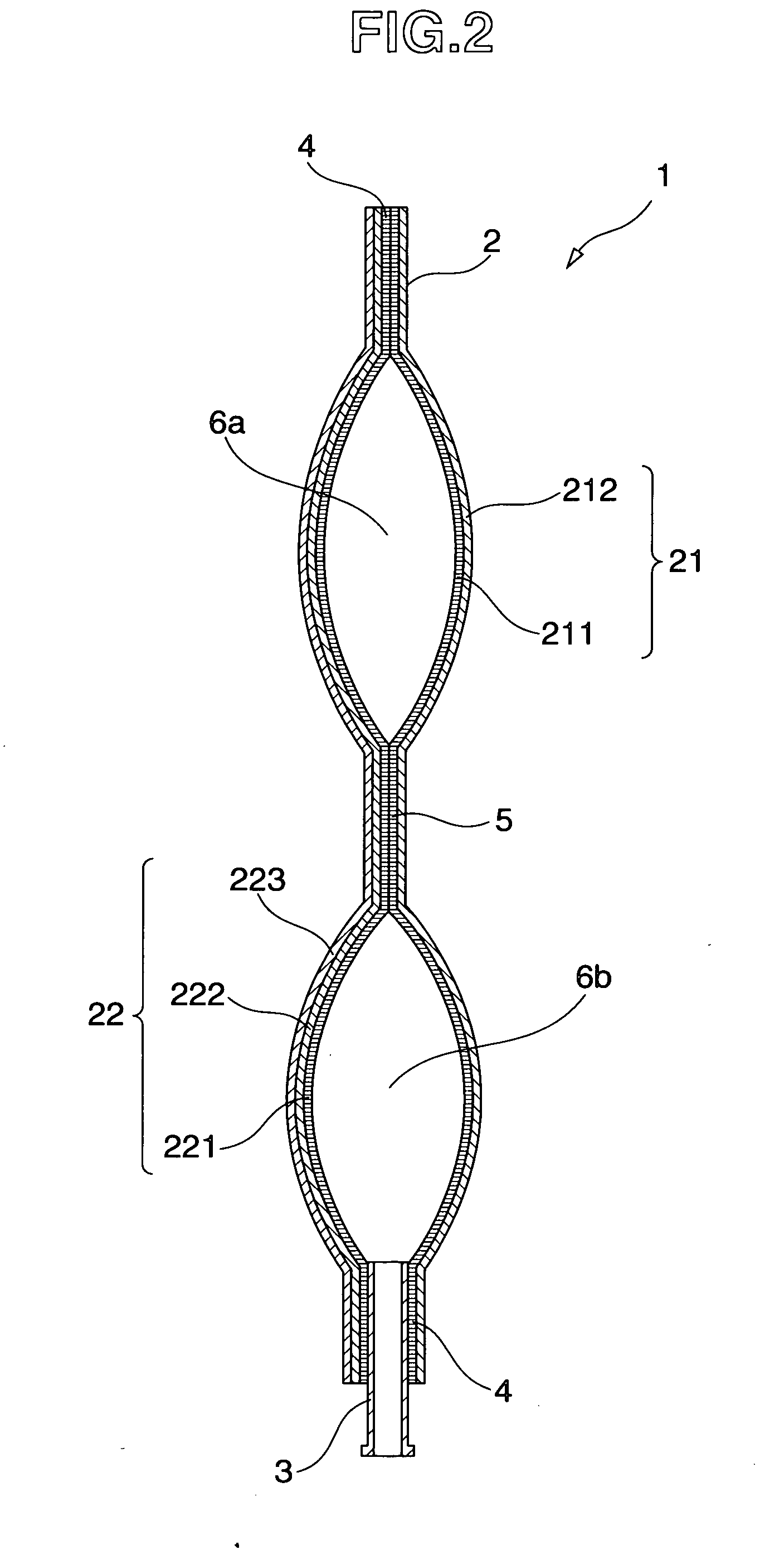

a dual chamber and packaging technology, applied in the field of dual chamber packages, can solve the problems of inability to completely remove inability to completely prevent the elution of monomer components or oligomer components, and the elution of additives or residual monomer components used in nylon and polypropylene, etc., to achieve excellent visibility of contents, high water vapor barrier properties, and high mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

[0098]After dry lamination of a 12 μm thick alumina-deposited polyethylene terephthalate (GL film, made by Toppan Printing Co., Ltd.) film to a 12 μm thick polyethylene terephthalate (an ester, made by Toyobo Co., Ltd.) by use of a two-part curing adhesive (polyester-urethane / isocyanate adhesive, made by Mitsui Takeda Chemicals Inc.), dry lamination was carried out by inserting a preliminarily formed three-layered sheet of a 20 μm thick linear low density polyethylene (Harmorex®, made by Japan Polyethylene Corporation), a 20 μm thick cyclic polyolefin (ZENOR®, made by Zeon Corporation) and a 30 μm thick linear low density polyethylene (Harmorex®, made by Japan Polyethylene Corporation), simultaneously with melt extrusion of a 20 μm thick linear low density polyethylene (Harmorex®, made by Japan Polyethylene Corporation) on the other surface of the polyethylene terephthalate film (an ester, made by Toyobo Co., Ltd.) as an adhesive resin, thereby providing a multi-layered sheet (I-1)....

example 2

[0104]A multi-layered sheet (I-2) was made in the same manner as in (I-1) of Example 1, and another multi-layered sheet (II-2) was made in such a way that after dry lamination of a 9 μm thick aluminium foil (made by Nippon Foil Mfg. Co., Ltd.) to a 12 μm thick polyethylene terephthalate (an ester, made by Toyobo Co., Ltd.) by use of a two-part curing adhesive (polyester-urethane / isocyanate adhesive, made by Mitsui Takeda Chemicals Inc.), dry lamination was carried out by inserting a preliminarily formed, 40 μm thick linear low density polyethylene (Harmorex®, made by Japan Polyethylene Corporation) film, simultaneously with melt extrusion of a 20 μm thick linear low density polyethylene (Harmorex®, made by Japan Polyethylene Corporation) on the other surface of the aluminium foil as an adhesive resin.

[0105]This multi-layered sheet (II-2) was one including the innermost layer of the 40 μm thick linear low density polyethylene (Harmorex®, made by Japan Polyethylene Corporation), the a...

example 3

[0107]After dry lamination of a 60 μm thick linear low density polyethylene (Harmorex®, Japan Polyethylene Co., Ltd.) film to a 12 μm thick polyethylene terephthalate (an ester, made by Toyobo Co., Ltd.) by use of a two-part curing adhesive (polyester-urethane / isocyanate adhesive, made by Mitsui Takeda Chemicals Inc.), sand lamination was carried out by inserting a preliminarily formed two-layered sheet of a 20 μm thick linear low density polyethylene (Harmorex®, made by Japan Polyethylene Corporation) and a 30 μm thick cyclic polyolefin (ZENOR®, made by Zeon Corporation), simultaneously with melt extrusion of a 20 μm thick linear low density polyethylene (Harmorex®, made by Japan Polyethylene Corporation) on the other surface of the polyethylene terephthalate as an adhesive resin, thereby providing a multi-layered sheet (I-3).

[0108]This multi-layered sheet (I-3) was one including the innermost layer of the 30 μm thick cyclic polyolefin (ZENOR®, made by Zeon Corporation), the adjace...

PUM

| Property | Measurement | Unit |

|---|---|---|

| total light transmittance | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com