Reciprocating compressor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

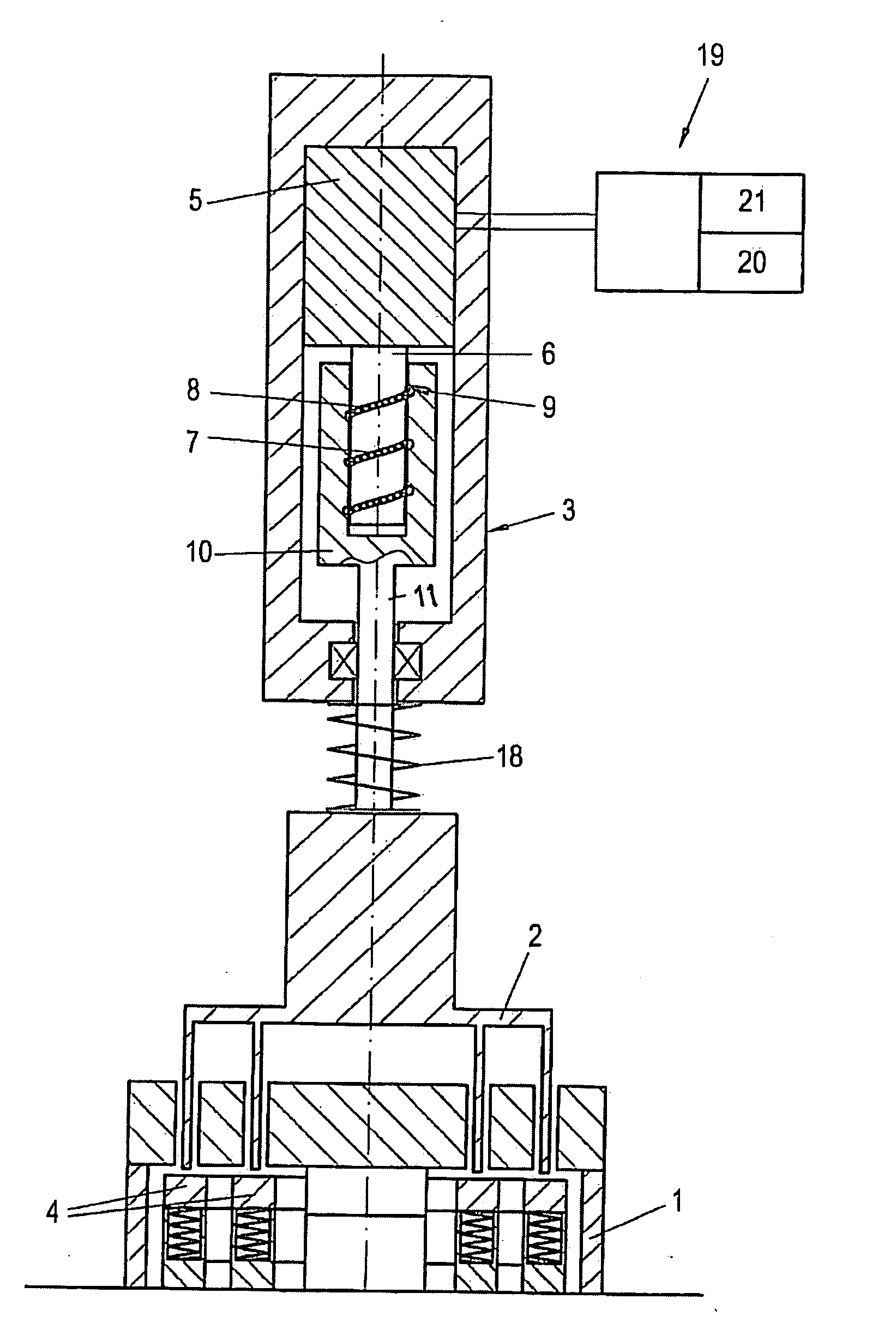

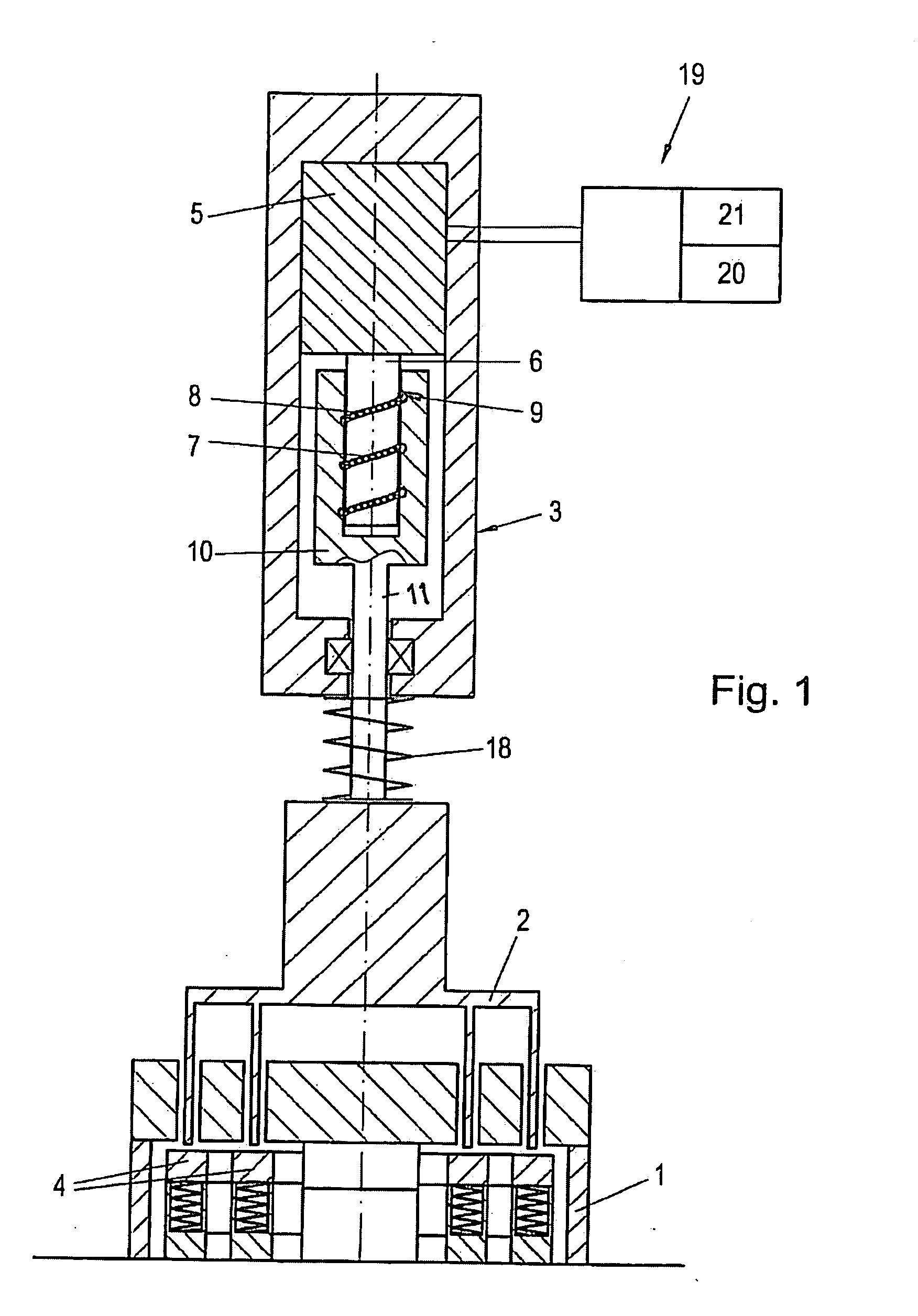

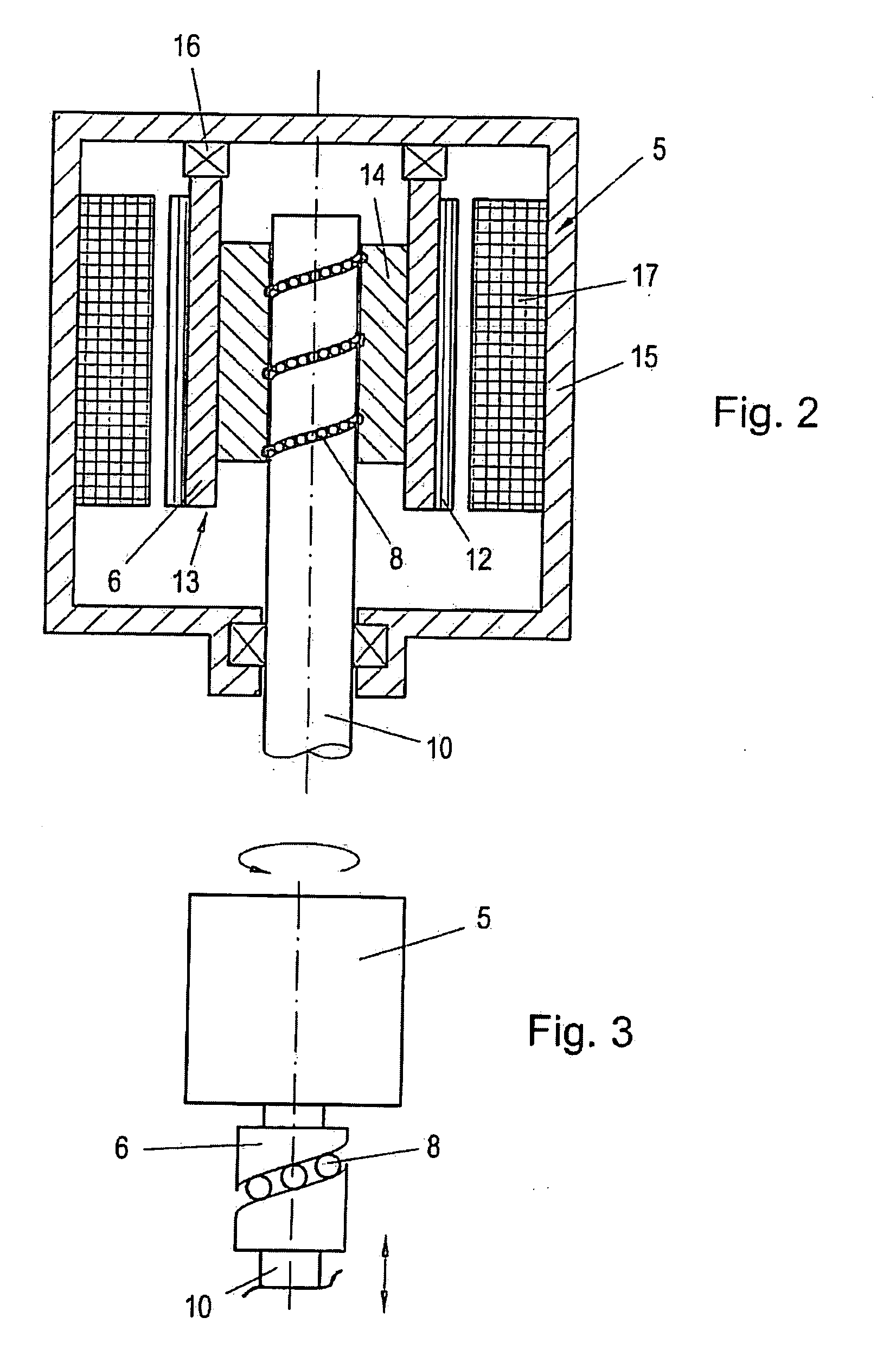

[0021]According to FIG. 1, a reciprocating compressor—not further shown—comprises a valve unloader 2 arranged at an automatically acting suction valve 1 of the compressor, said valve unloader holding open two ring-shaped sealing elements 4 of the suction valve 1 over a controllable portion of the compressor's cycle by means of an electrically operated actuation device 3. For this purpose, the actuation device 3 comprises as drive an electric motor 5, whose driven element 6 (developed here as a central shaft) comprises a guide surface 7 (here circumferential spiral groove) extending in an inclined manner in rotational direction for low-friction rolling elements 8, which on the other hand interact with a counter-guide 9 extending in an inclined manner at a non-rotating lifting element 10, the latter being connected to the valve unloader 2.

[0022]As soon as the electric motor 5 is supplied with current, its driven element 6 rotates, which, in conjunction with the non-rotating lifting el...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com