Methods of Modifying Surface Coverings to Embed Conduits Therein

a technology of surface coverings and conduits, which is applied in the direction of heating types, lighting and heating apparatus, and ways, etc., can solve the problems of insufficient utilization of heat energy from such structures, insufficient use of fossil fuels to generate energy, and harmful to the environment, so as to improve the efficiency of the system, and increase the temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

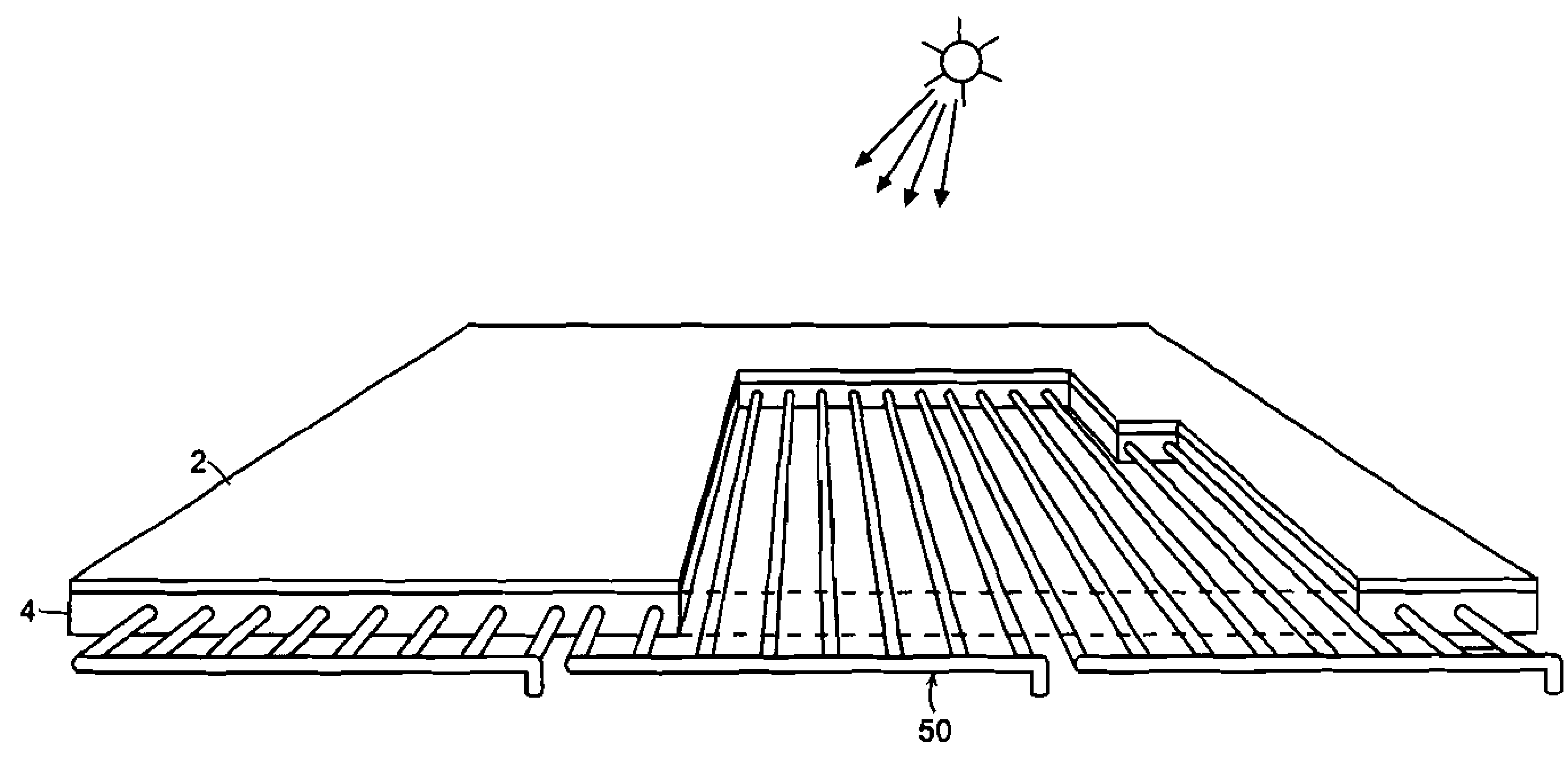

[0039]FIG. 1 is a schematic drawing of a retrofitted / modified surface covering for use of solar heat energy formed in accordance with the present invention. The surface covering has a top layer 2 and a lower layer 4 and in order to form the surface covering, the top layer and middle layer are ground away such that a network of conduits 50 can be installed in the recess formed by grinding. The network of conduits 50 carry fluid to be heated and the network is installed in, on, under or in contact with all or a portion of the surface covering, preferably in the layer 4 (or 14 as shown in FIGS. 5 and 6) which are high thermal conductivity layers.

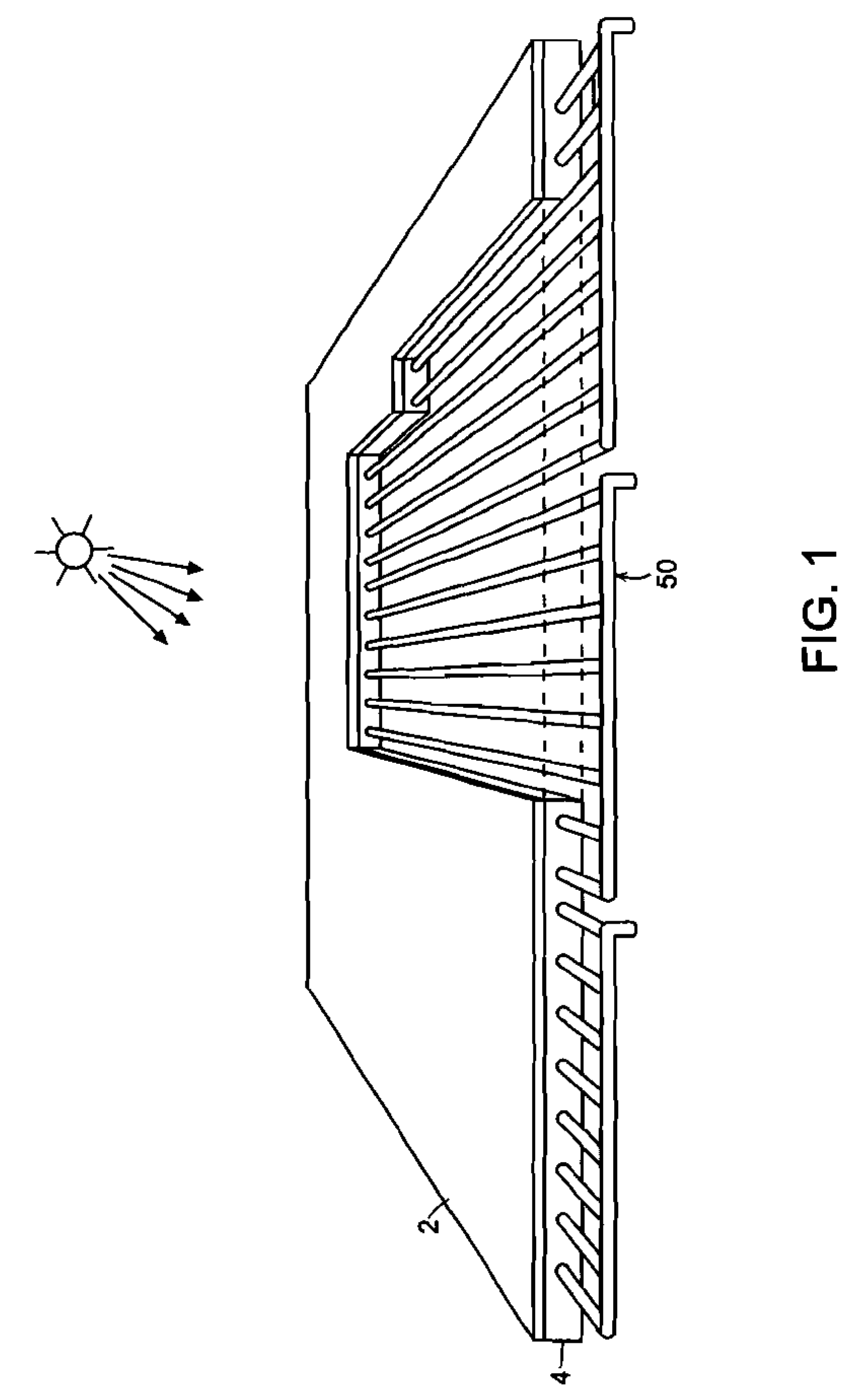

[0040]The method of modifying an existing surface covering to embed conduits therein to collect solar heat is shown in FIG. 2 where an existing surface covering 7 is removed with a grinder 6 which can be part of a piece of equipment, such as equipment moved by a vehicle 5. The equipment can be driven by an operator or could be a hand-driven pie...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface area | aaaaa | aaaaa |

| surface area | aaaaa | aaaaa |

| surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com