Lithographic machine platform and applications thereof

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022]The spirit of the present invention relates to a lithographic machine platform and applications thereof, which forms a patterned layer used as a hard mask layer or other applications on a substrate by using the high lithographic properties of an electron beam or an ion beam. According to the above-mentioned description, the utilization and selection of the material of a precursory thing and a patterned layer, or the variations of process parameters are both within a spiritual scope of the present invention.

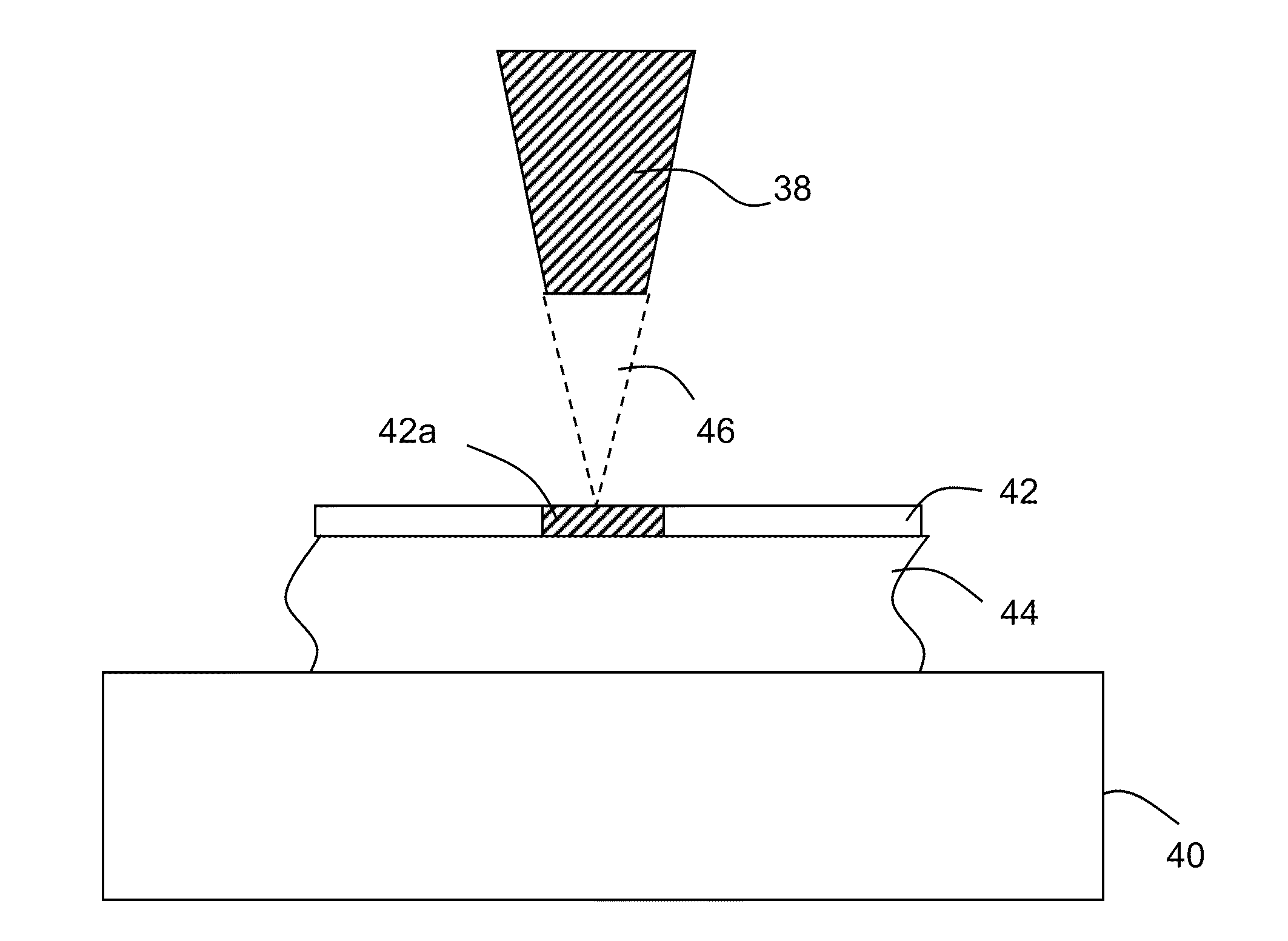

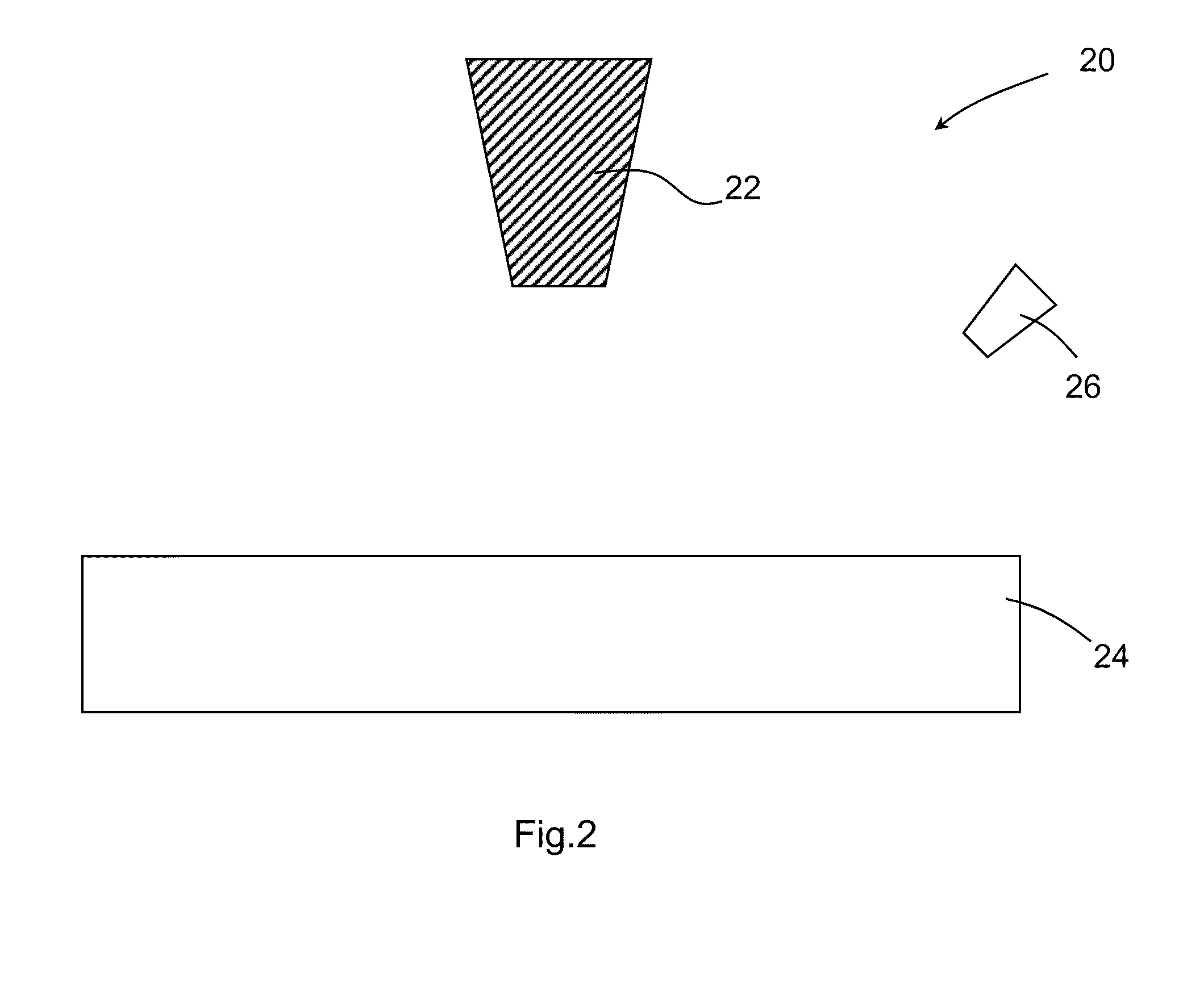

[0023]Refer to FIG. 2, which are diagrams schematically showing the first configuration of the lithographic machine platform according to the present invention. As shown in FIG. 2, an electron beam or an ion beam lithographic machine platform 20 of the present invention comprises: an electron beam or an ion beam generator 22; a substrate supporting platform 24 positioned below the electron beam generator or the ion beam generator 22; and a precursory gas injector 26 injectin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Dielectric polarization enthalpy | aaaaa | aaaaa |

| Metallic bond | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com