Lubricant composition

a technology of lubricant composition and composition, which is applied in the direction of lubricant composition, liquid carbonaceous fuel, fuel, etc., can solve the problems of affecting diesel engines, so as to improve the resistance to degradation and improve the performance of lubricant composition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples

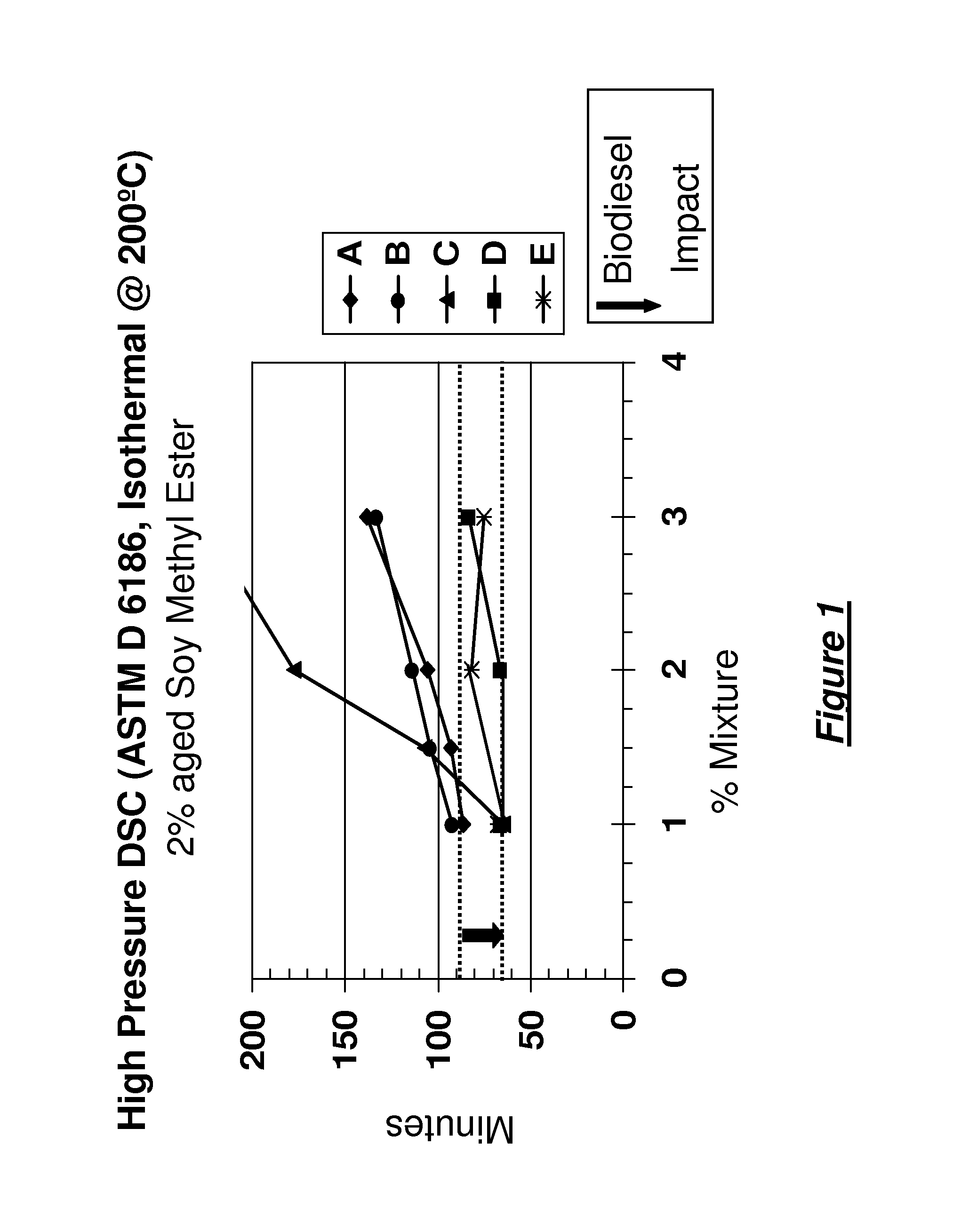

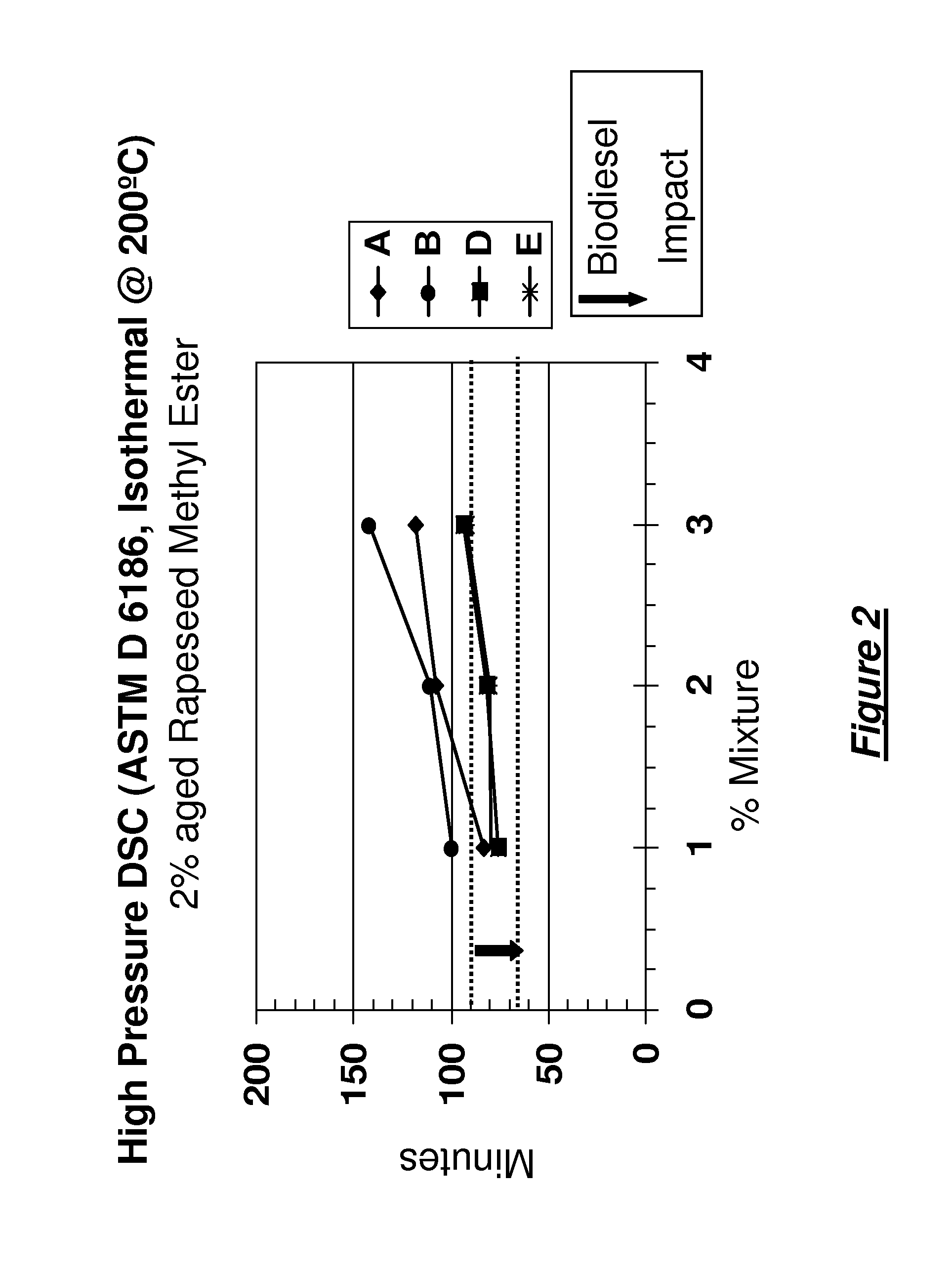

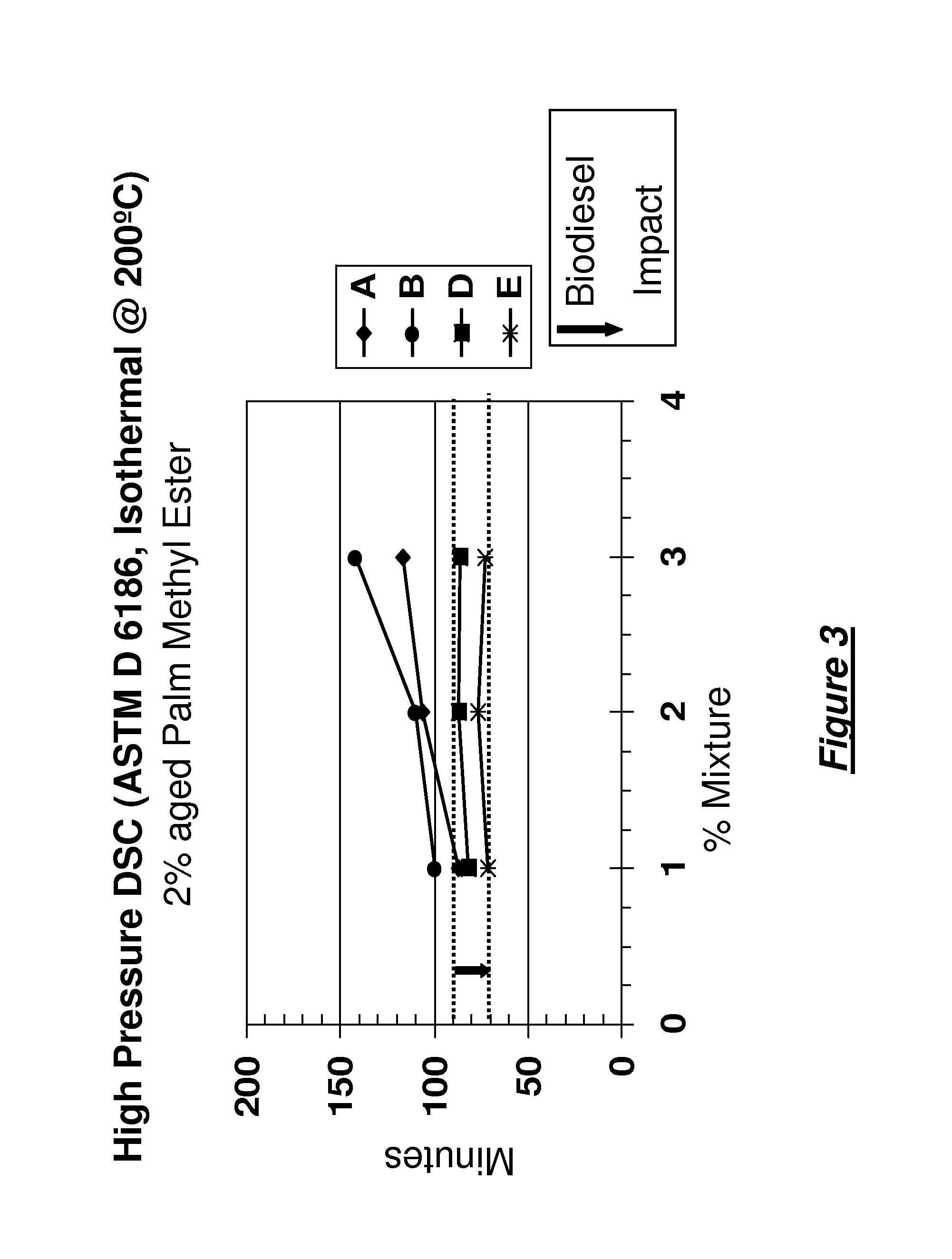

[0091]Two mixtures of antioxidants (Mixtures A and B) are formed according to this invention. Three comparative mixtures (Comparative Mixtures C, D, and E) are also formed but do not represent this invention.

[0092]More specifically, Mixture A is an 80 / 20 weight ratio of a mixture of octylated / butylated diphenylamine and thiodiethylene bis[3-(3,5-di-tert-butyl-4-hydroxyphenyl)propionate].

[0093]Mixture B is an 80 / 20 weight ratio of a mixture of octylated / butylated diphenylamine and octylated phenyl-alpha-naphthylamine.

[0094]Comparative Mixture C is a diisobutylene reaction product of a mixture of diphenylamine and phenothiazine as prepared according to Example 1 of U.S. Pat. No. 5,503,759.

[0095]Comparative Mixture D is a 1 / 1 weight ratio of a mixture of octylated / butylated diphenylamine and 3-(3,5-di-tetrabutyl-4-hydroxyphenyl)propionic acid isooctyl ester.

[0096]Comparative Mixture E is a 1 / 1 weight ratio of a mixture of octylated / butylated diphenylamine and 4,4-methylene-bis(2,6-di-t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| weight percent | aaaaa | aaaaa |

| viscosity index | aaaaa | aaaaa |

| weight percent | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com