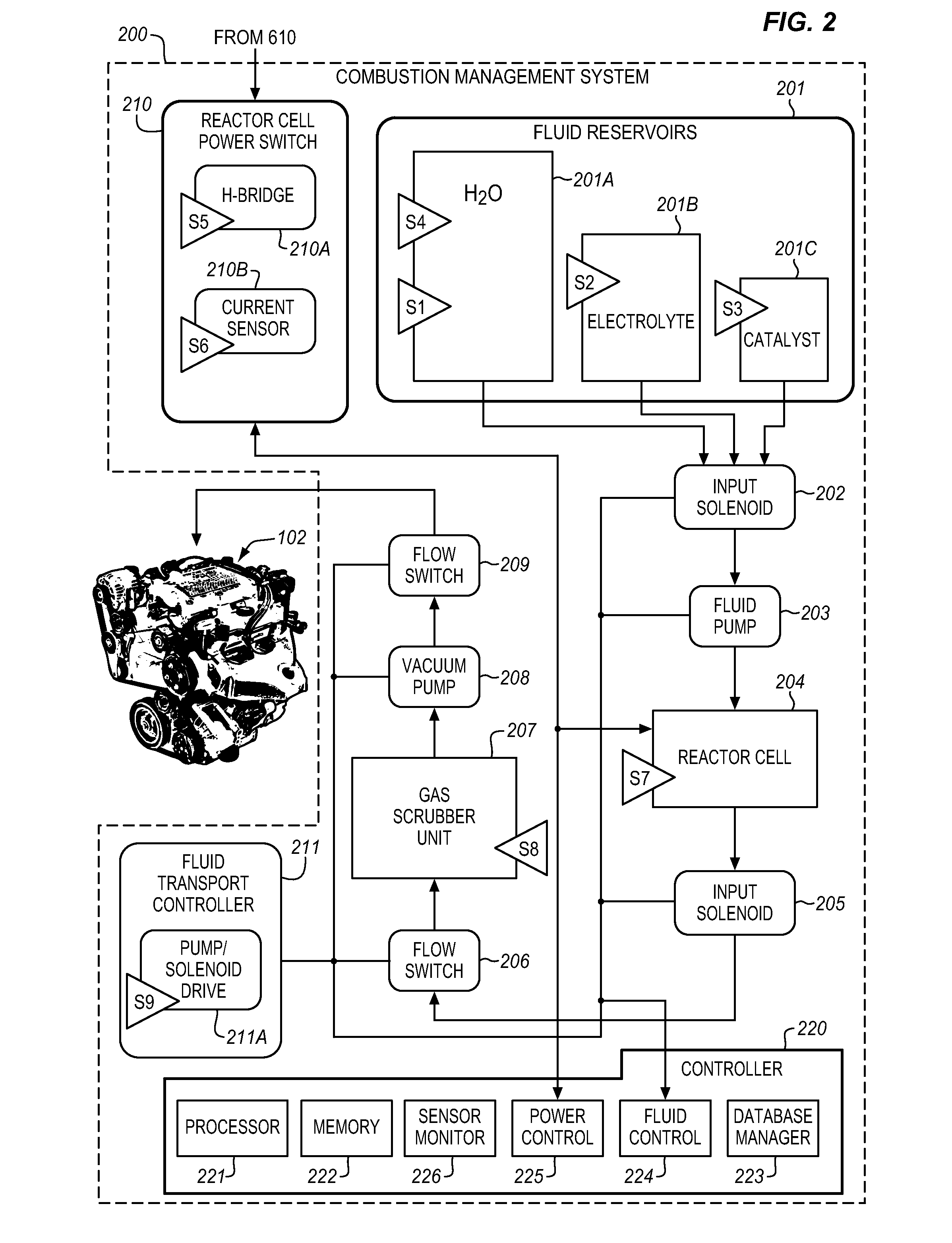

[0021]The present

Product Gas Generator For Producing A Substantially Stoichiometric Mix Of

Hydrogen And

Oxygen (termed “Product

Gas Generator” herein) works in conjunction with a Combustion

Management System, which models each

hydrocarbon combustion application, and the Product

Gas Generator supplies a

product gas, comprising a dynamic mixture of nascent

hydrogen (H) and

oxygen (O), to the

internal combustion engine to propagate the formation of

hydroxide radicals (OH) and thereby to improve the level of completion of the hydrocarbon

combustion reaction. Atomic

hydrogen (or nascent hydrogen) is the species denoted by H (atomic), contrasted with di-hydrogen, the usual “hydrogen” (H2) commonly involved in chemical reactions. Being monatomic, nascent hydrogen (H) atoms are much more reactive and, thus, a much more effective

reducing agent than ordinary diatomic H2 atoms. The Combustion Management System provides product gas volumetric requirement information and takes into account the engine style, primary torque requests, and hydrocarbon fuel consumption information to develop an

operating system specific application that produces consistent measurable results. Stoichiometric models are used versus

trial and error data obtained from running the engine on a dynomometer through various load and engine speed conditions, which saves time and money while insuring that each Combustion Management System application is adequate for its intended use.

[0028]Unlike the HRM, which introduces a competitive reaction into the

internal combustion engine, this approach directly addresses the

primary reaction driving the hydrocarbon combustion mechanism toward completion. This approach creates a twofold increase in the reactive tendency toward completion.

Hydroxide radicals (OH) are lighter than the standard diatomic

oxygen (O2) being administered, which allows for greater diffusivity and an increased potential for oxidative continuance to supersede

polymerization. Also, the higher oxidative potential of the

hydroxide radicals (OH) allow for

carbon chain cleaving reactions, thus creating more reactive sites on the hydrocarbon molecules and greater reaction distribution.

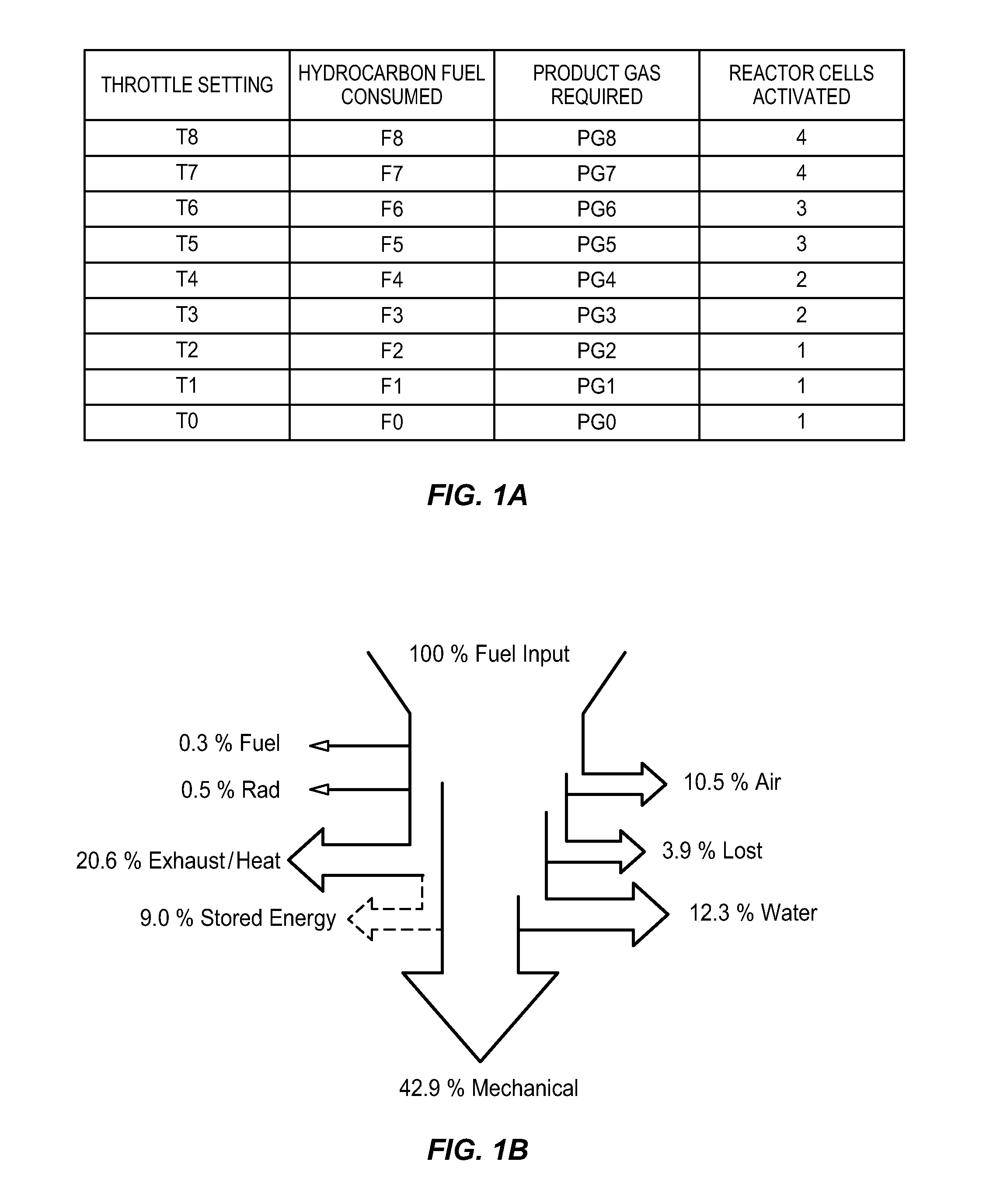

[0029]Fuel savings are achieved as a result of extracting more

stored energy from each hydrocarbon molecule. Every carbon-carbon and carbon-

hydrogen bond in the cylinders of the internal combustion engine represents

stored energy that could be translated into mechanical work. By promoting a higher degree of oxidative completion, the Combustion Management System extracts more energy from the hydrocarbon fuel. Similarly, emissions of particulate matter, hydrocarbons, and

carbon monoxide from the internal combustion engine are a direct result of this hydrocarbon combustion not propagating to completion. Therefore, furthering the combustive process has a direct and measurable

impact on both fuel consumption and emissions reduction.

[0030]As noted above,

polymerization is a problem in combustive reactions; and the primary causes of

polymerization within an engine cylinder are fuel

droplet size, turbulence, air composition, molecule size, and

reaction mechanism. The Combustion Management System addresses each of these dynamics to ensure successful and consistent reductions. The product gas

injection port not only administers the activated gas but also is designed to increase turbulence and ensure homogeneous mixing. Fuel injectors are modified or replaced to optimize

droplet size and injection timing. The activated

reaction mechanism generates more molecules of smaller size and greater separation. All of these factors combine to facilitate a near total reduction of particulate matter emissions.

[0031]The Combustion Management System is geared toward increasing the reactivity of the hydrocarbon fuel itself. By increasing the number of

active carbon sites in the fuel, which is present in the cylinders of the internal combustion engine, the statistical probability of oxygen reacting in the desired fashion is dramatically improved. Also, the addition of nascent hydrogen (H) in stoichiometric balance with oxygen (O) nullifies the competition between the hydrogen (H) and carbon (C) for oxidation. Also, the creation of more

active carbon sites reduces

residence time of

active oxygen and decreases the statistical probability that

nitrogen and oxygen will collide during the optimum temperature threshold.

Reaction rate reductions also serve to limit the timeframe where

NOx formation is energetically feasible.

Login to View More

Login to View More